SJ gasoline engine oil composition, preparation method thereof and application thereof

A technology for gasoline engine oil and composition, applied in the field of materials, can solve the problems of increasing fuel and lubricating oil consumption, reducing the effective power of the engine, black sludge, etc., and achieving the effect of reducing emissions and maintaining effective power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

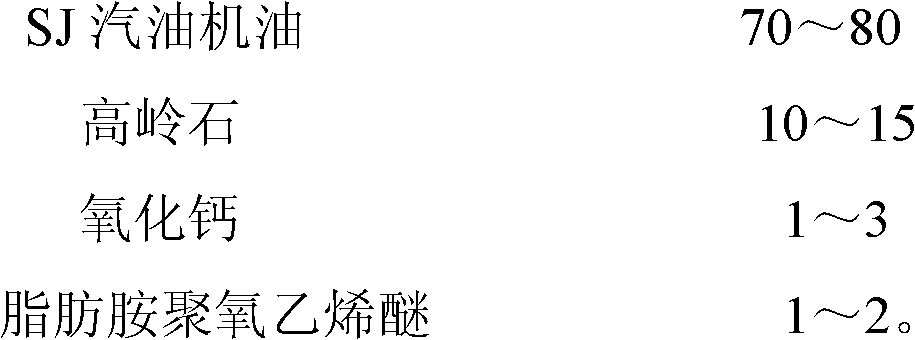

Method used

Image

Examples

Embodiment 1

[0020] ①After drying the kaolinite at 400°C for 3 hours, grind it in a ball mill to a particle size of no more than 1 micron;

[0021] ② Weigh 10g of kaolinite obtained in step ①, 70g of SJ gasoline engine oil, 1g of calcium oxide, 1g of fatty amine polyoxyethylene ether and mix them into a homogenizer with a closed device to make the vacuum degree reach -0.08MPa;

[0022] ③Raise the temperature to 85°C, stir at 10000rmp for 30min, adjust the rotation speed to 18000rmp for 10min, and adjust the rotation speed to 28000rmp for 5min;

[0023] ④ Finely disperse in an 80W, 35KHz ultrasonic generator for 10 minutes.

[0024] The prepared new lubricant was subjected to a wear test on a MMW-1 vertical universal friction and wear machine with a test force of 800N and a rotational speed of 2000r / min. After 5 hours of wear test, the sample changed from 2.9550g to 2.9561g, and the weight loss was -0.037%, which means that the sample not only did not decrease, but also increased in weight...

Embodiment 2

[0026] ①After drying the kaolinite at 400°C for 3 hours, grind it in a ball mill to a particle size of no more than 1 micron;

[0027] ② Weigh 13g of kaolinite obtained in step ①, 75g of SJ gasoline engine oil, 2g of calcium oxide, 1.6g of fatty amine polyoxyethylene ether and mix them into a homogenizer with a closed device to make the vacuum degree reach -0.08MPa;

[0028] ③Raise the temperature to 85°C, stir at 10000rmp for 30min, adjust the rotation speed to 18000rmp for 10min, and adjust the rotation speed to 28000rmp for 5min;

[0029] ④ Finely disperse in an 80W, 35KHz ultrasonic generator for 10 minutes.

[0030] The prepared new lubricant was subjected to a wear test on a MMW-1 vertical universal friction and wear machine with a test force of 800N and a rotational speed of 2000r / min. After 5 hours of wear test, the sample changed from 2.9576g to 2.9589g, and the weight loss was -0.04%, which means that the sample not only did not decrease, but also increased in weigh...

Embodiment 3

[0032] ①After drying the kaolinite at 400°C for 3 hours, grind it in a ball mill to a particle size of no more than 1 micron;

[0033] ② Weigh 15g of kaolinite obtained in step ①, 80g of SJ gasoline engine oil, 3g of calcium oxide, 2g of fatty amine polyoxyethylene ether and mix them into a homogenizer with a closed device to make the vacuum degree reach -0.08MPa;

[0034] ③Raise the temperature to 85°C, stir at 10000rmp for 30min, adjust the rotation speed to 18000rmp for 10min, and adjust the rotation speed to 28000rmp for 5min;

[0035] ④ Finely disperse in an 80W, 35KHz ultrasonic generator for 10 minutes.

[0036] The prepared new lubricant was subjected to a wear test on the MMW-1 vertical universal friction and wear machine with a test force of 800N and a speed of 2000r / min. After 5 hours of wear test, the sample changed from 2.9671g to 2.9682g, and the weight loss was -0.037%, which means that the sample not only did not decrease, but also increased in weight. The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com