Formula SLX speed engine oil composition and preparation method and application thereof

A composition and engine oil technology, applied in the field of materials, can solve the problems of increased fuel and lubricating oil consumption, reduced engine effective power, black sludge, etc., to achieve the effect of reducing emissions and maintaining effective power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] ①Grind the mullite in a ball mill until the particle size is no more than 1 micron, and dry it at 360°C for 3 hours;

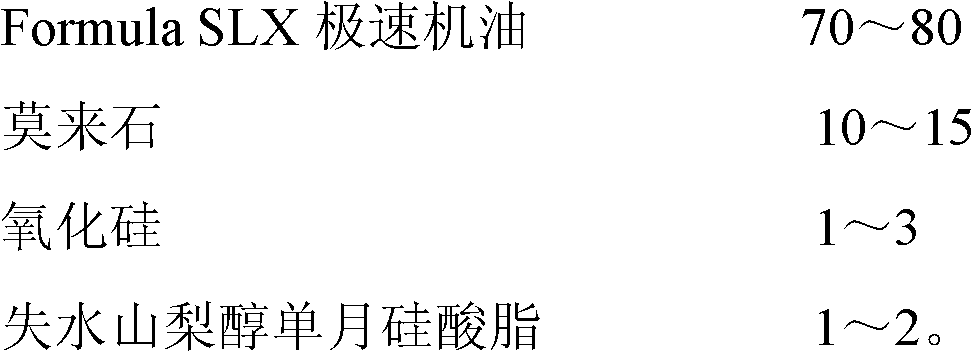

[0022] ②In parts by mass, weigh 10g of mullite obtained in step ①, 70g of Formula SLX extreme speed engine oil, 1g of silicon oxide, and 1g of sorbitan monolaurate, mix them into a homogenizer with a closed device, and make the vacuum The degree reaches -0.08MPa;

[0023] ③Raise the temperature to 85°C, stir at 10000rmp for 30min, adjust the speed to 18000rmp and stir for 10min, adjust the speed to 28000rmp and stir for 5min;

[0024] ④ Finely disperse in an 80W, 35KHz ultrasonic generator for 10 minutes.

[0025] The prepared new lubricant was tested on the MMW-1 vertical universal friction and wear machine with a test force of 600N and a speed of 2000r / min. After 5 hours of wear test, the sample changed from 2.9650g to 2.9658g, the weight loss was -0.027%, and the sample increased in weight. The coefficient of friction dropped from 0.037 to 0.033, ...

Embodiment 2

[0027] ①Grind the mullite in a ball mill until the particle size is no more than 1 micron, and dry it at 360°C for 3 hours;

[0028] ②In parts by mass, weigh 13g of mullite obtained in step ①, 75g of Formula SLX extreme speed engine oil, 2g of silicon oxide, 1.5g of sorbitan monolaurate and mix them into a homogenizer with a closed device, so that The vacuum degree reaches -0.08MPa;

[0029] ③Raise the temperature to 85°C, stir at 10000rmp for 30min, adjust the speed to 18000rmp and stir for 10min, adjust the speed to 28000rmp and stir for 5min;

[0030] ④ Finely disperse in an 80W, 35KHz ultrasonic generator for 10 minutes.

[0031] The prepared new lubricant was tested on the MMW-1 vertical universal friction and wear machine with a test force of 600N and a speed of 2000r / min. After 5 hours of wear test, the sample changed from 2.9586g to 2.9595g, the weight loss was -0.030%, and the sample increased in weight. The coefficient of friction dropped from 0.033 to 0.028, a re...

Embodiment 3

[0033] ①Grind the mullite in a ball mill until the particle size is no more than 1 micron, and dry it at 360°C for 3 hours;

[0034] ②In parts by mass, weigh 15g of mullite obtained in step ①, 80g of Formula SLX extreme speed engine oil, 3g of silicon oxide, and 2g of sorbitan monolaurate, mix them into a homogenizer with a closed device, and make the vacuum The degree reaches -0.08MPa;

[0035] ③Raise the temperature to 85°C, stir at 10000rmp for 30min, adjust the speed to 18000rmp and stir for 10min, adjust the speed to 28000rmp and stir for 5min;

[0036] ④ Finely disperse in an 80W, 35KHz ultrasonic generator for 10 minutes.

[0037] The prepared new lubricant was tested on the MMW-1 vertical universal friction and wear machine with a test force of 600N and a speed of 2000r / min. After 5 hours of wear test, the sample changed from 2.9691g to 2.9698g, the weight loss was -0.024%, and the sample increased in weight. The coefficient of friction dropped from 0.035 to 0.030, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com