Gas flow control device

A technology of air flow control device and control cavity, applied in the direction of control valve, valve device, functional valve type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

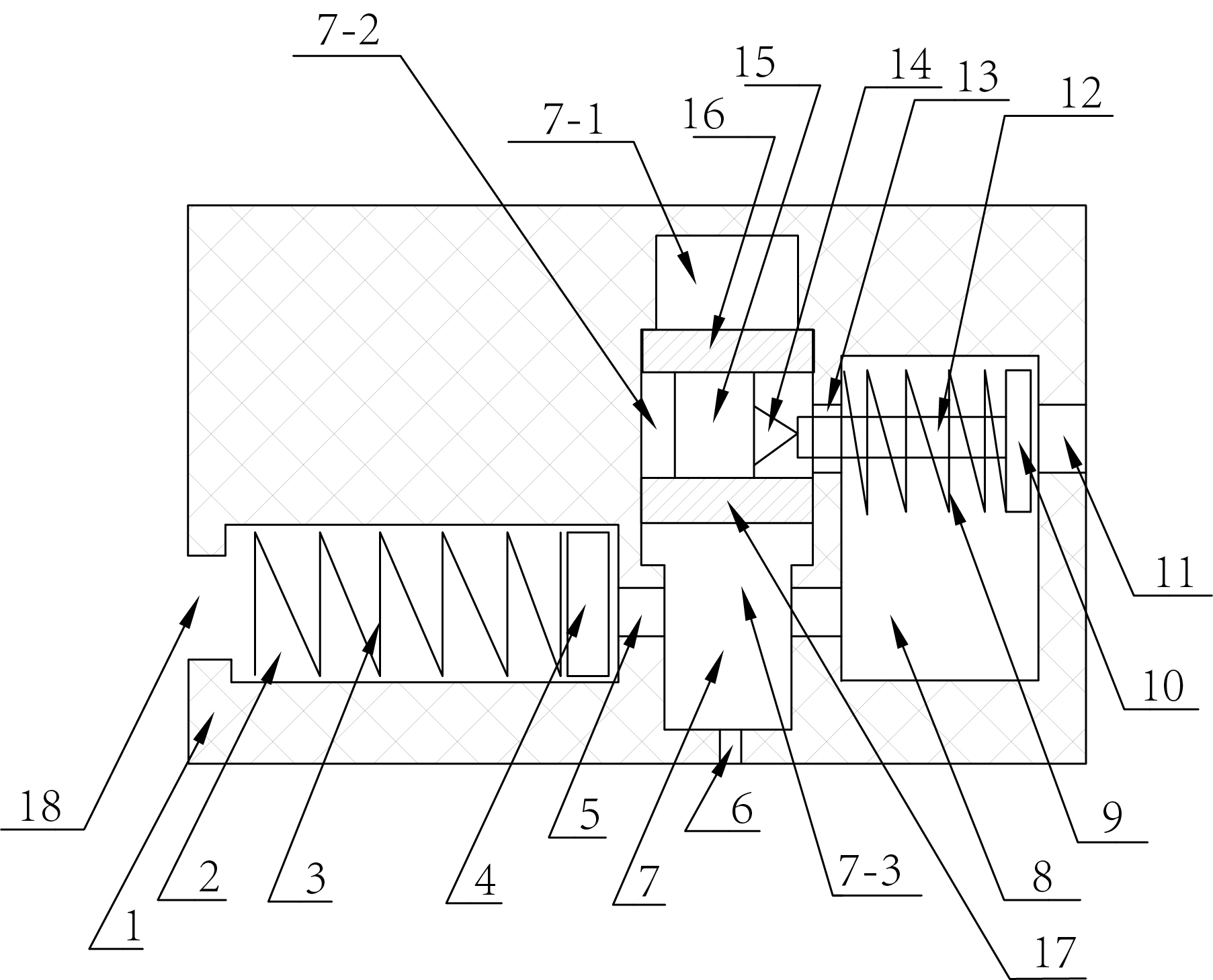

Embodiment 1

[0022] Such as figure 1 , this embodiment includes a main body 1, in which an inflation and exhaust chamber 7 with an inflation and exhaust port 6, an inflation control chamber 2 with an inflation hole 18 and a deflation control chamber with an exhaust hole 11 are arranged. Cavity 8; an air channel 5 is provided between the inflation and exhaust cavity body 7 and the inflation control cavity 2. An air passage is also provided between the inflation and exhaust cavity body 7 and the deflation control cavity 8 .

[0023] The inflatable control chamber 2 is installed with an inflatable end cap 4 for blocking the air passage 5 between the inflatable and exhaust chamber 7 and the inflatable control chamber 2, and the inflatable end cap 4 is connected to a Inner inflatable end elastomer 3. The deflation control cavity 8 is equipped with a deflation end cap 10 for blocking the vent hole 11, and the deflation end cap 10 is connected with a deflation end elastic body 9 located in the...

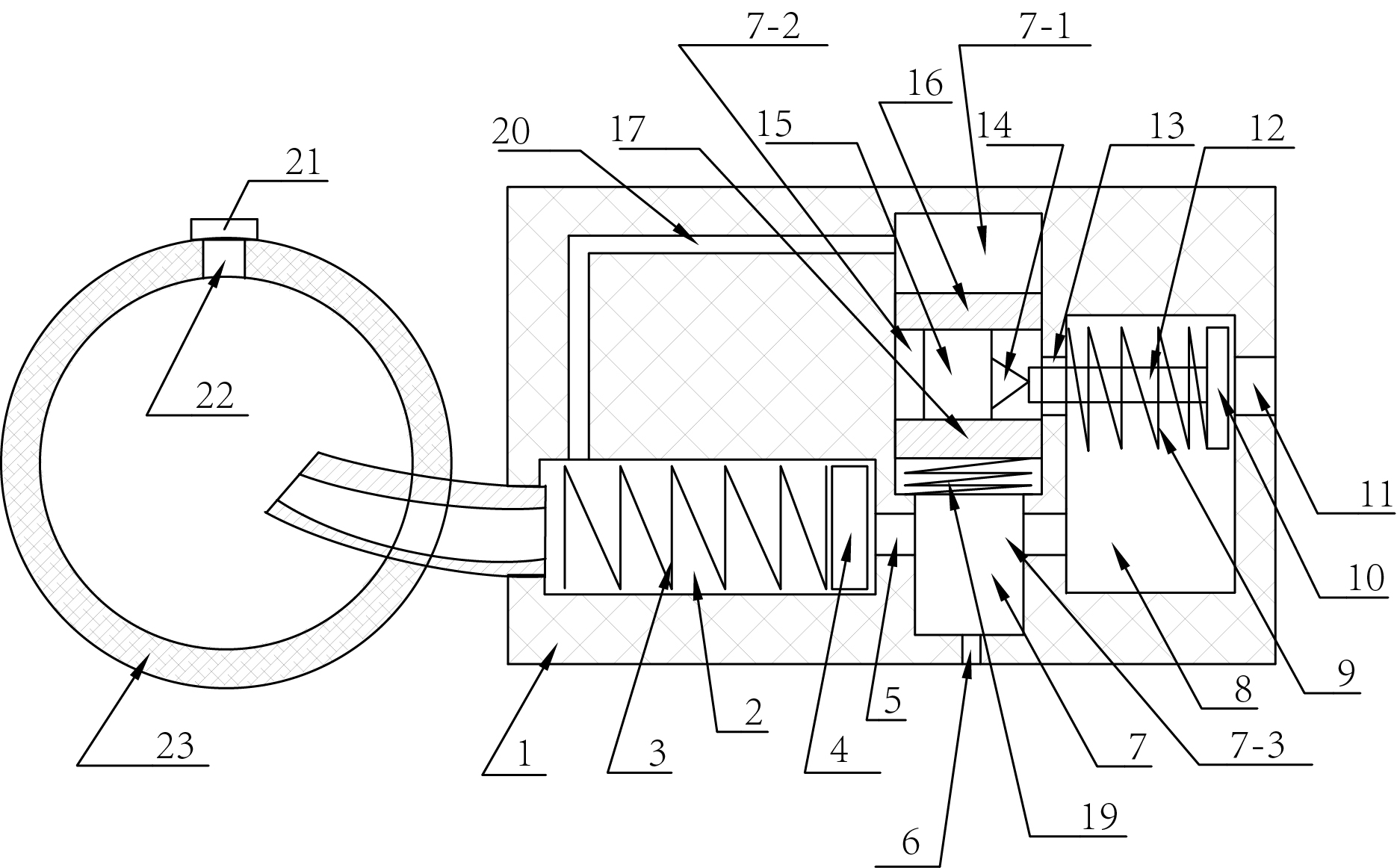

Embodiment 2

[0026] Such as figure 2 , on the basis of Embodiment 1, this embodiment also includes an auxiliary air bag 23 with an air filling hole 22, and an inflation check valve 21 is installed in the air filling hole 22, and the auxiliary air bag 23 is connected to the air filling hole. 18 in communication; it also includes a control air passage 20 opened in the body 1, one end of the control air passage 20 communicates with the first cavity 7-1, and the other end communicates with the inflation control chamber 2; it also includes a control air passage installed in the second The return elastic body 19 between the sealing head 17 and the cavity wall of the third cavity 7-3. The auxiliary air bag 23 is placed in the air container. The auxiliary airbag 22 is used to inflate an air container (such as an airbag, balloon, pipeline, etc.).

[0027] When inflating the gas container, the gas in the third cavity 7-3 presses against the second head 17, so that the connecting rod 15 moves axia...

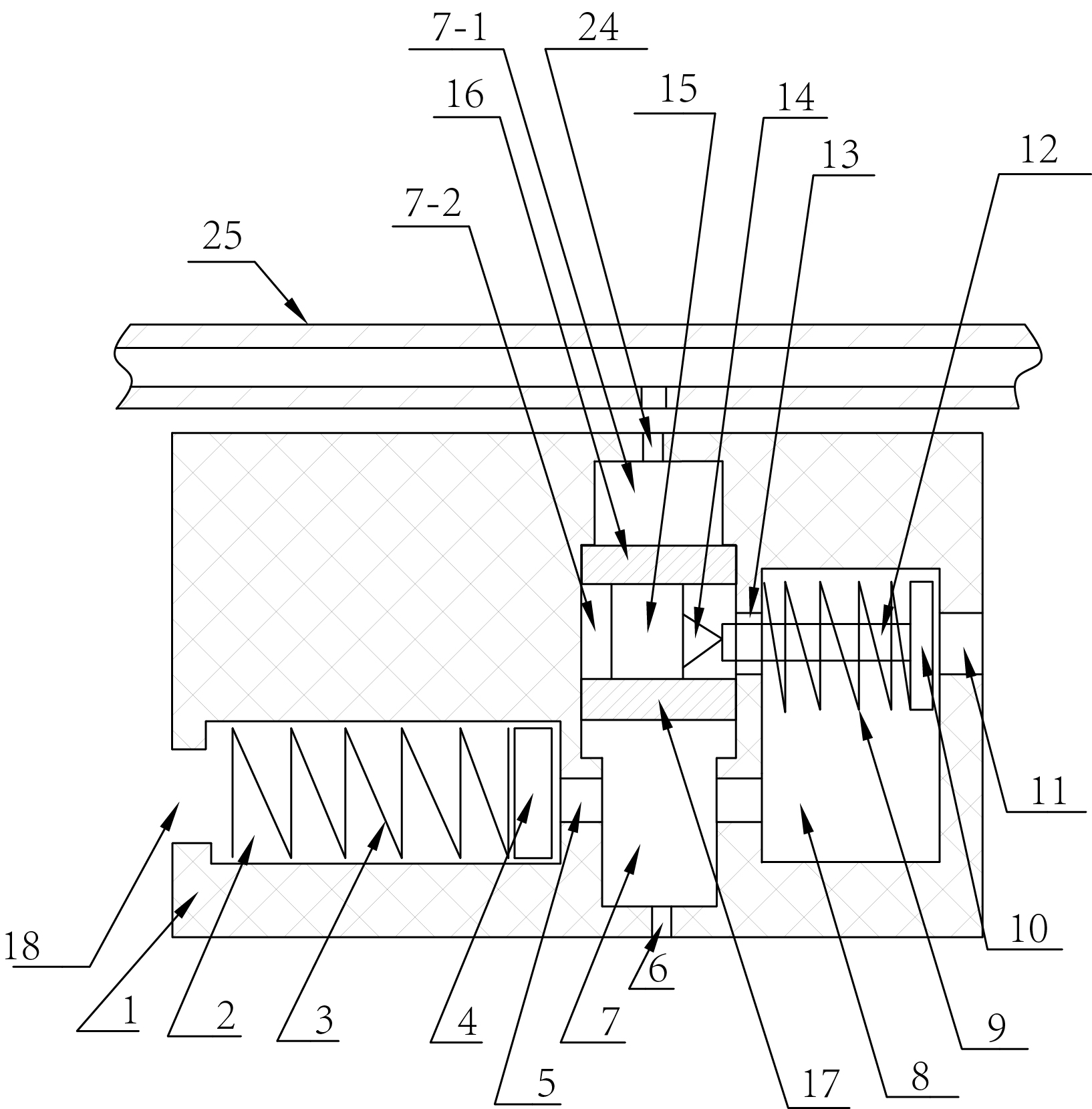

Embodiment 3

[0029] Such as image 3 , on the basis of Embodiment 1, it also includes a control air pipe 25; and a control air hole 24 communicated with the first cavity 7-1 is opened on the body 1; the control air pipe 25 communicates with the first cavity through the control air hole 24 Body 7-1 is connected.

[0030] When the gas container is deflated, first press the first head 16 by controlling the air pipe 25, so that the outer end of the lock block 14 and the end head rod 12 of the deflation end are separated from extrusion, so as to open the vent hole 11 more smoothly. Then the gas container is deflated by the inflation and deflation control device 3 . During use, control air pipe 25 as normal pressure or high pressure gas as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com