Light-regulating structure of automobile headlamp

A technology for automotive headlamps and headlamps, which is applied in the field of dimming structures for automotive headlamps, can solve the problems of damage to dimming rods and lifter threads, scrapped headlamp assemblies, falling off reflectors, and the like. The effect of quick disassembly, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

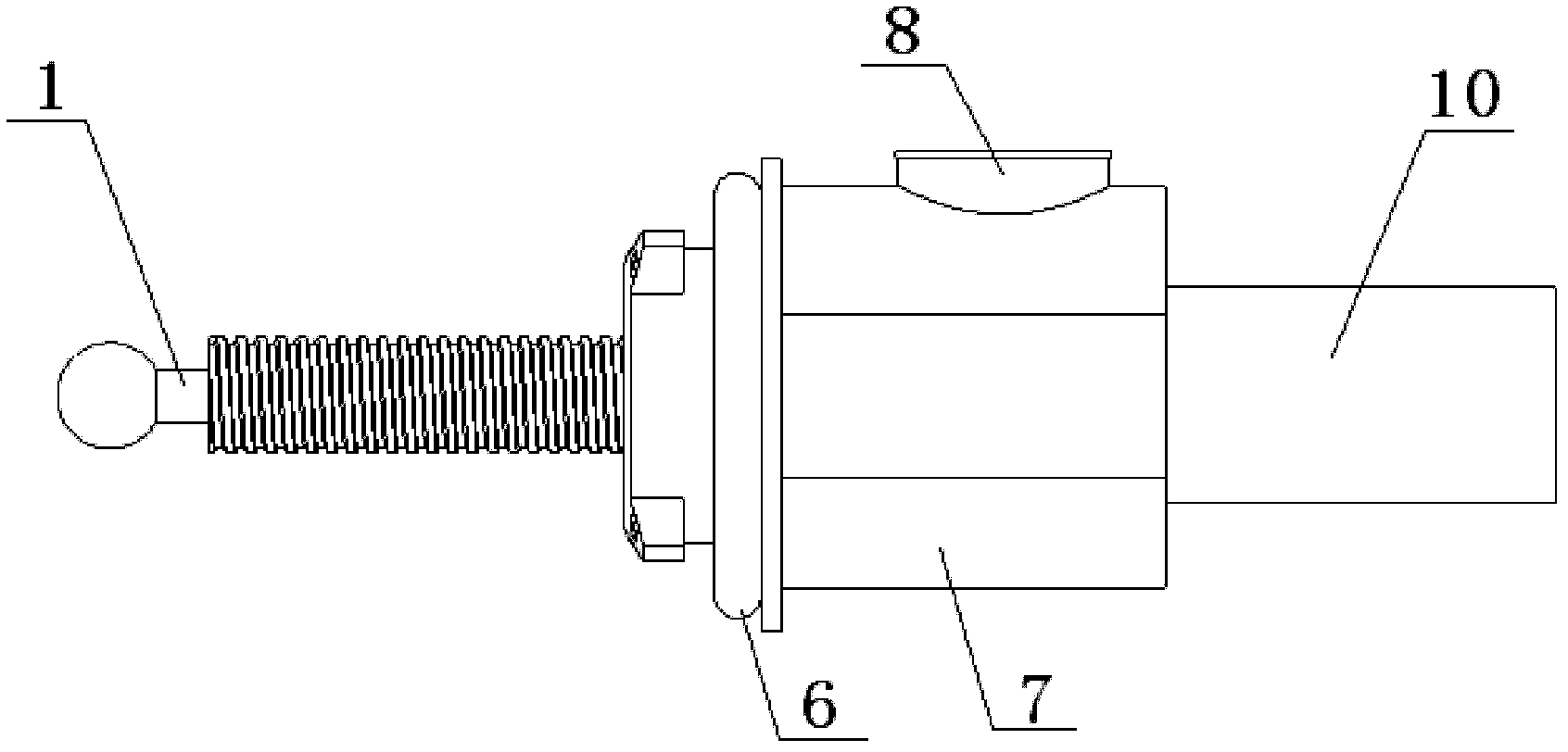

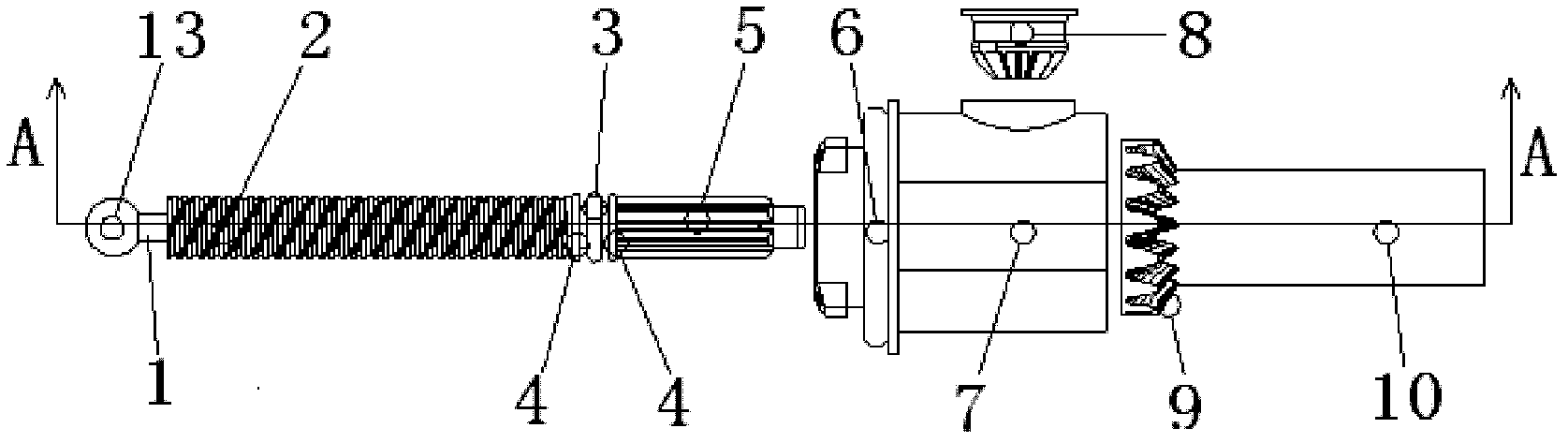

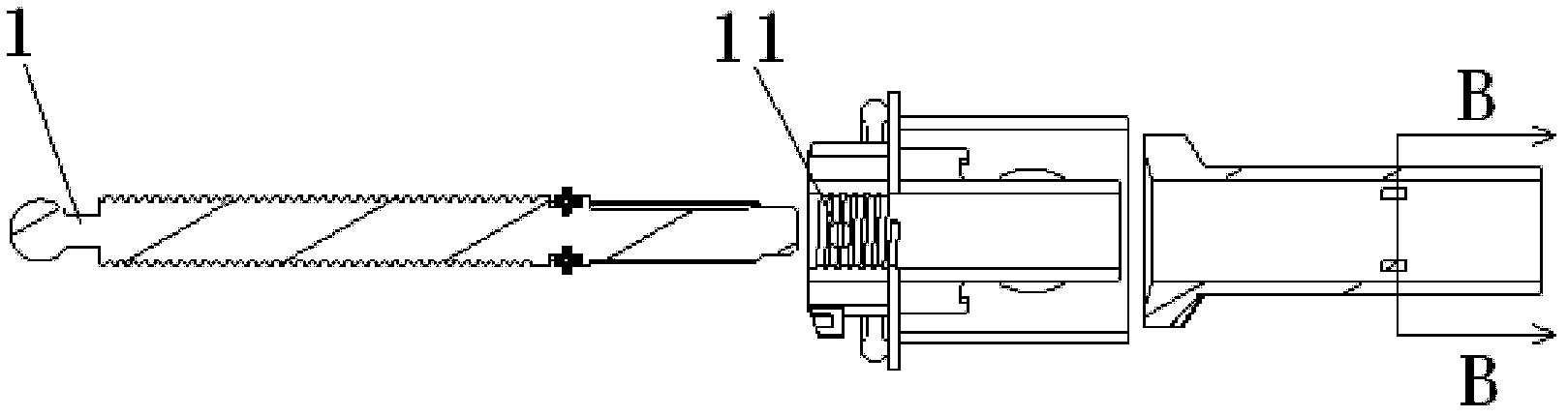

[0018] Such as Figure 1-2 As shown, the present invention uses an external dimming structure to be clamped to the headlight housing and separated from the headlight assembly, which is convenient for replacement and maintenance.

[0019] In the present invention, the light adjusting rod 1 is inserted into the mounting base 7, and the light adjusting rod threaded section 2 engages with the thread 11 of the mounting base; the connector 10 is sleeved into the other end of the installation base 7, and the jump tooth 12 inside the connector 10 is sleeved in On the dimmer gear section 5; the side of the mounting base 7 is provided with an adjustment knob 8 that engages with the connector gear 9. The adjustment knob 8 is rotated to drive the dimmer lever 1 to adjust the headlight, and the connector 10 The internal jump tooth 12 realizes a self-protection function when over-adjusted.

[0020] Two limit rings 4 are arranged between the threaded section 2 of the light adjusting rod and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com