Super-smooth surface defect detection system and distortion correction method thereof

An ultra-smooth surface and defect detection technology, which is applied in the direction of optical testing flaws/defects, can solve problems such as difficult to achieve, result length, curvature error, and high cost of optical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] An example of the application of the present invention to an ultra-smooth surface defect detection system and its distortion correction method is as follows.

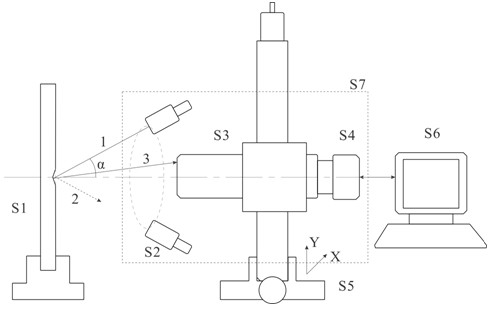

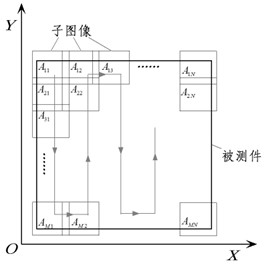

[0068] like figure 1 As shown, the ultra-smooth surface defect detection system includes a two-dimensional guide device S5, a computer S6, an optical microscopic imaging device S7, a standard plate S8 and a clamping device S9 for the standard plate, and the optical microscopic imaging device S7 includes an LED ring lighting source S2, variable magnification microscope S3, CCD detector S4; CCD detector S4, variable magnification microscope S3, and LED ring lighting source S2 are sequentially connected to form the optical microscopic imaging device S7 of the detection system, and the CCD detector S4 communicates with the The computer S6 is connected, the optical microscopic imaging device S7 is placed on the two-dimensional shifting device S5, and the two-dimensional shifting device S5 drives the optical microscopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com