Clopidogrel hydrochloride tablet

A technology of clopidogrel hydrochloride and polyvinylpyrrolidone, applied in the field of clopidogrel hydrochloride tablets and its preparation, can solve the problems of poor stability of clopidogrel and easy sticking in the production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

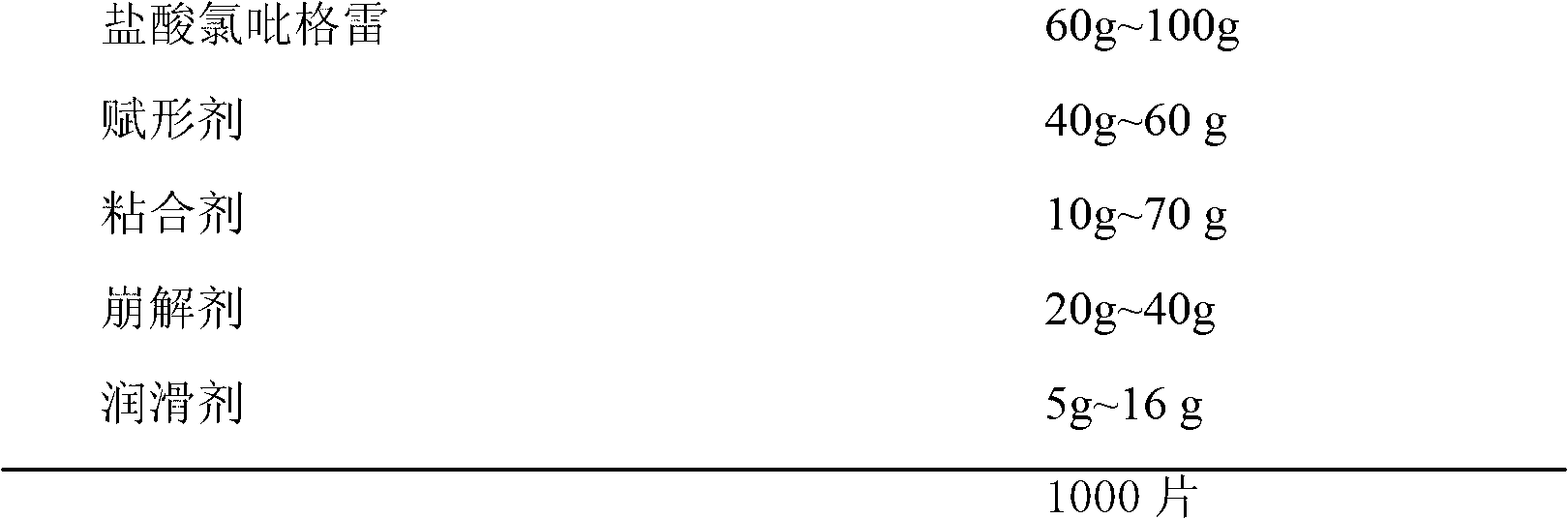

[0057] Embodiment 1: tablet

[0058]

[0059]

[0060] Preparation:

[0061] Clopidogrel hydrochloride was crushed through a 100-mesh sieve, polyethylene glycol 6000 and silicon dioxide were respectively passed through a 100-mesh sieve, polyvinylpyrrolidone, mannitol, and low-substituted hydroxypropyl cellulose were respectively passed through a 80-mesh sieve, and hydrogenated castor oil was passed through a 100-mesh sieve Sieve; after mixing 60% silicon dioxide and clopidogrel hydrochloride, add polyethylene glycol 6000, polyvinylpyrrolidone, low-substituted hydroxypropyl cellulose and mannitol and mix evenly in equal amounts; granulate, and calculate the dryness Granule yield, add hydrogenated castor oil and the remaining 40% of silicon dioxide, mix for 15-20 minutes, compress into tablets, and coat.

Embodiment 2

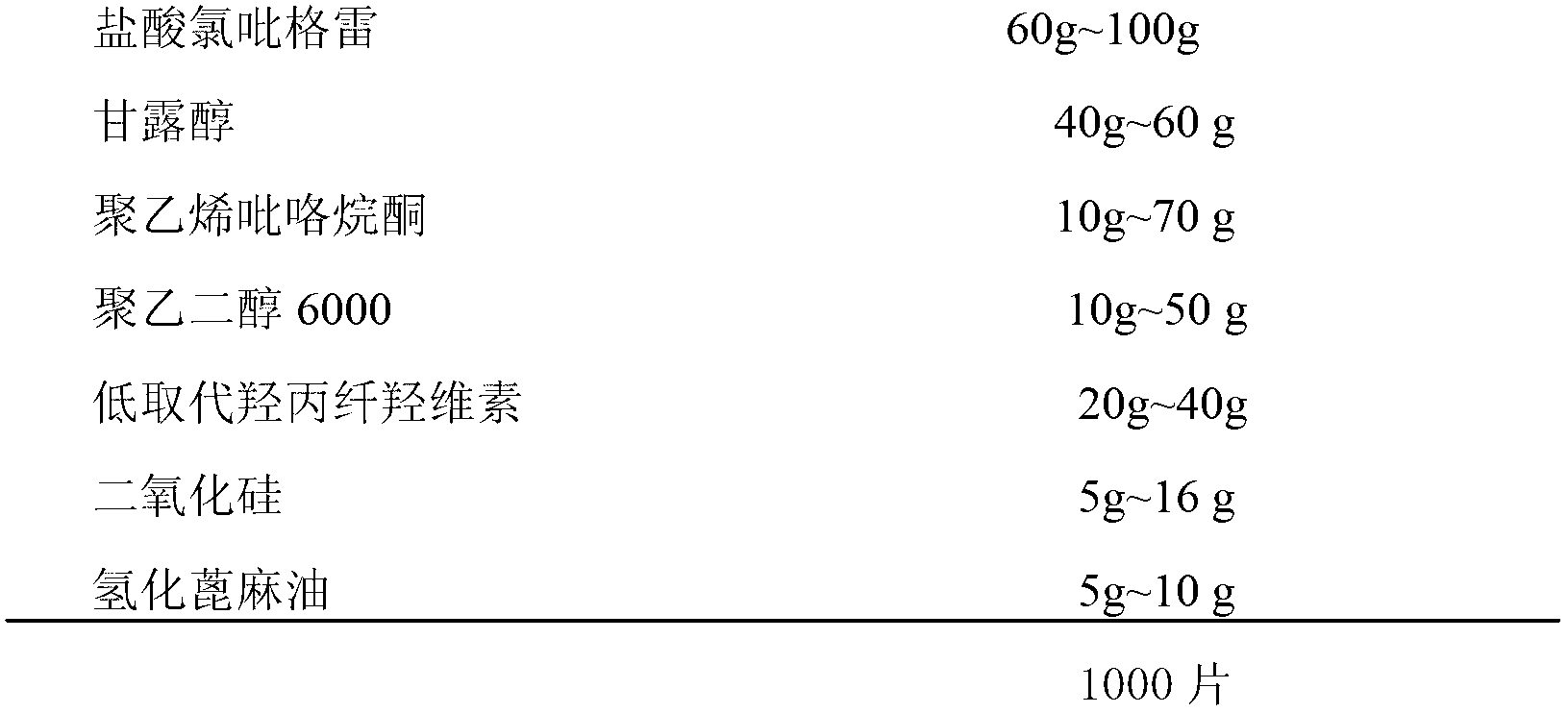

[0062] Embodiment 2: tablet

[0063]

[0064] Preparation:

[0065] Clopidogrel hydrochloride was crushed through a 100-mesh sieve, polyethylene glycol 6000 and silicon dioxide were respectively passed through a 100-mesh sieve, polyvinylpyrrolidone, mannitol, and low-substituted hydroxypropyl cellulose were respectively passed through a 80-mesh sieve, and hydrogenated castor oil was passed through a 100-mesh sieve Sieve; after mixing 60% silicon dioxide and clopidogrel hydrochloride, add polyethylene glycol 6000, low-substituted hydroxypropyl cellulose, polyvinylpyrrolidone and mannitol and mix in equal increments; granulate, Calculate the yield of dry granules, add hydrogenated castor oil and the remaining 40% of silicon dioxide, mix for 15 minutes, compress into tablets, and coat.

Embodiment 3

[0066] Embodiment 3: tablet

[0067]

[0068]

[0069] Preparation:

[0070]Clopidogrel hydrochloride was crushed through a 100-mesh sieve, polyethylene glycol 6000 and silicon dioxide were respectively passed through a 100-mesh sieve, polyvinylpyrrolidone, mannitol, and low-substituted hydroxypropyl cellulose were respectively passed through a 80-mesh sieve, and hydrogenated castor oil was passed through a 100-mesh sieve Sieve; after mixing 60% silicon dioxide and clopidogrel hydrochloride, add polyethylene glycol 6000, low-substituted hydroxypropyl cellulose, polyvinylpyrrolidone and mannitol and mix in equal increments; granulate, Calculate the yield of dry granules, add hydrogenated castor oil and the remaining 40% of silicon dioxide, mix for 5 minutes, compress into tablets, and coat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com