Single-crystal crystal forms of clopidogrel hydrochloride and preparation method and application thereof

A technology of clopidogrel hydrochloride and single crystal crystal form is applied in the application field of treatment and prevention of atherosclerotic thrombosis, and can solve problems such as the influence of platelet lifespan and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

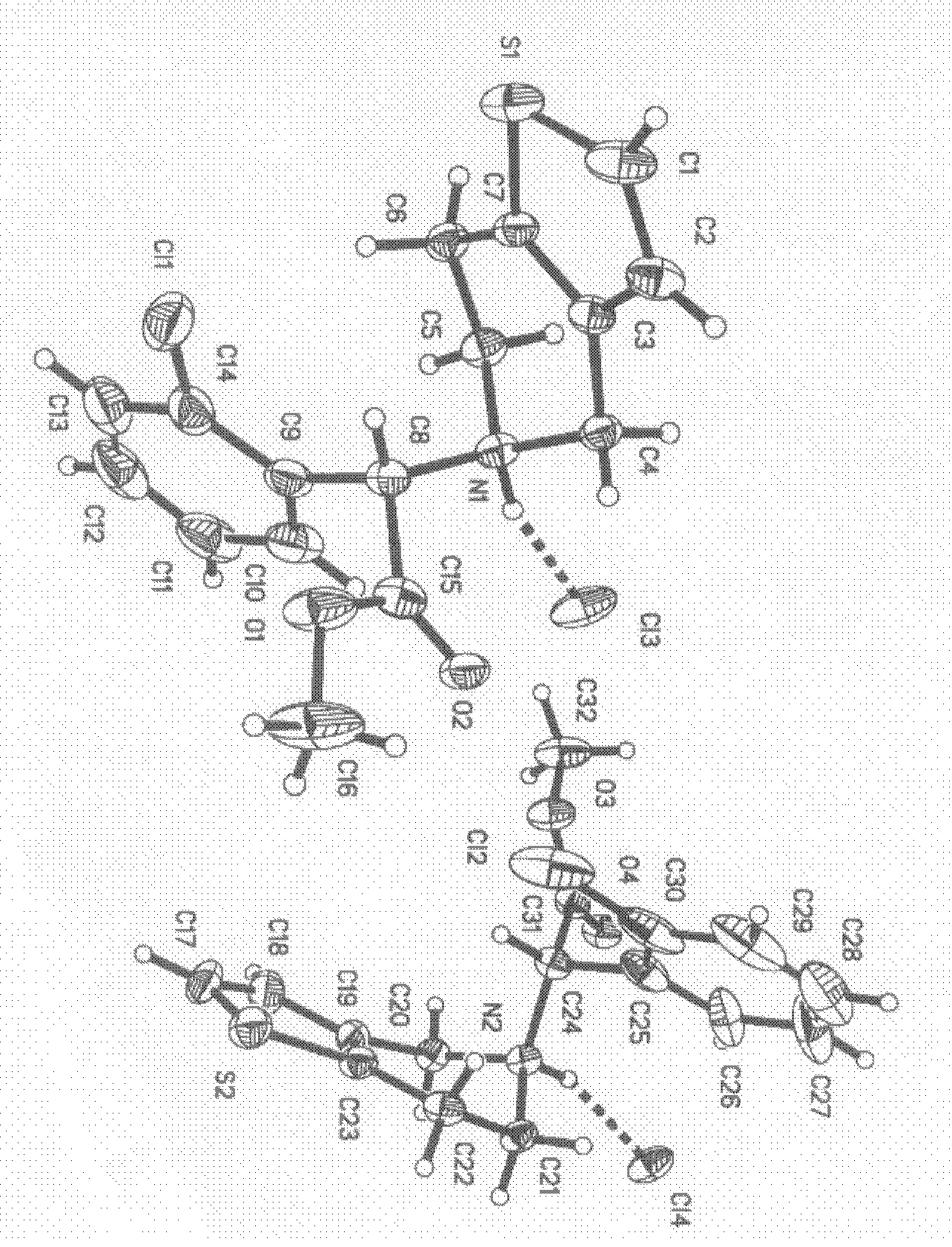

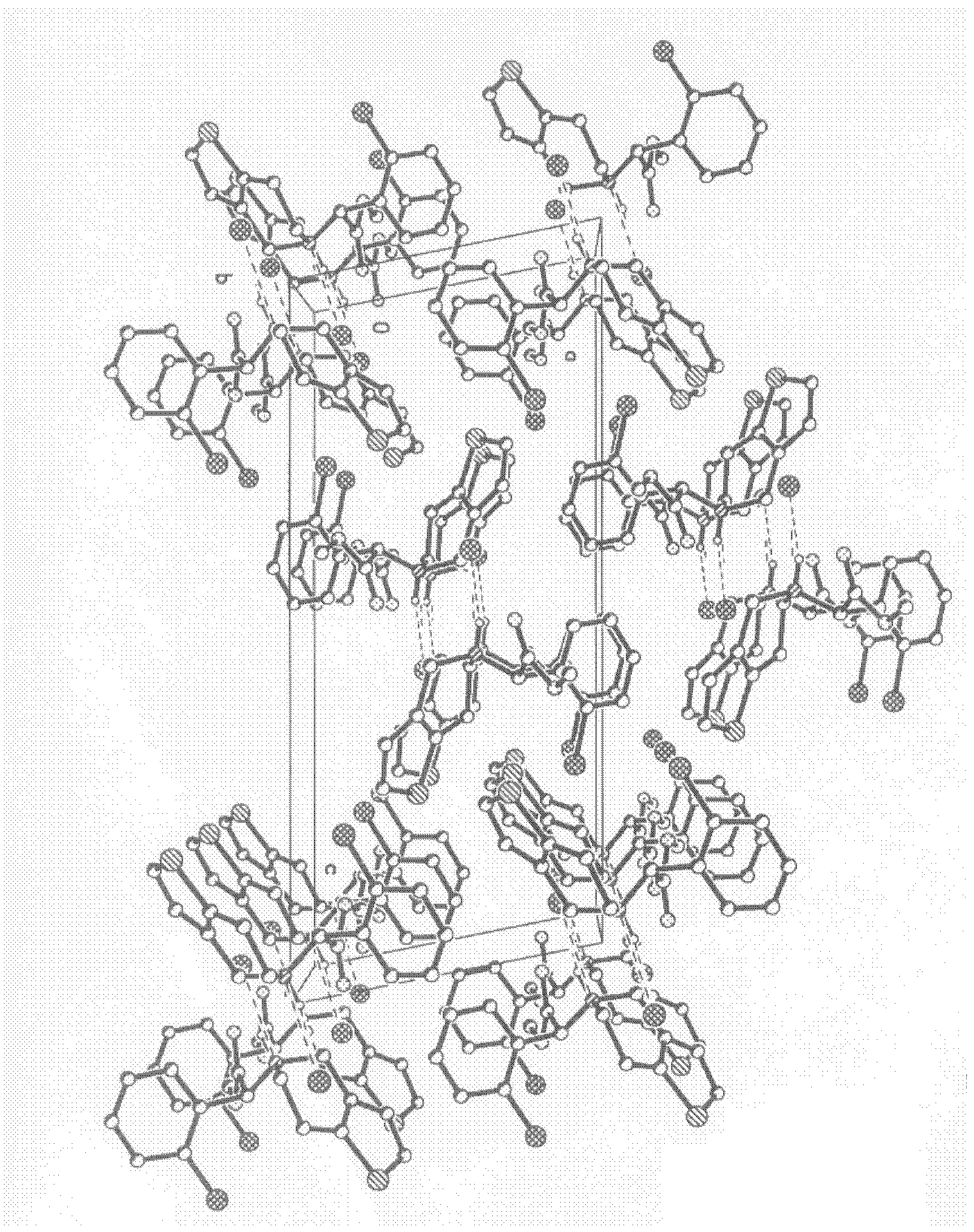

[0022] Embodiment 1: the preparation method of single crystal form of clopidogrel hydrochloride

[0023] Weigh 50 mg of clopidogrel hydrochloride, add 2 ml of acetone and heat to 40°C to dissolve it completely, then cool down to room temperature, slowly add 40 ml of diethyl ether dropwise, and let it stand at room temperature for 2 days to obtain a colorless block single crystal, which is filtered by suction. Example 2: Preparation method of clopidogrel hydrochloride single crystal crystal

Embodiment 2

[0024] Weigh 50mg of clopidogrel hydrochloride, add 2ml methyl ethyl ketone and heat to 40°C to dissolve it completely, then cool down to room temperature, slowly add 40ml diethyl ether dropwise, and let it stand at room temperature for 2 days to obtain a colorless blocky single crystal, which is filtered by suction .

Embodiment 3

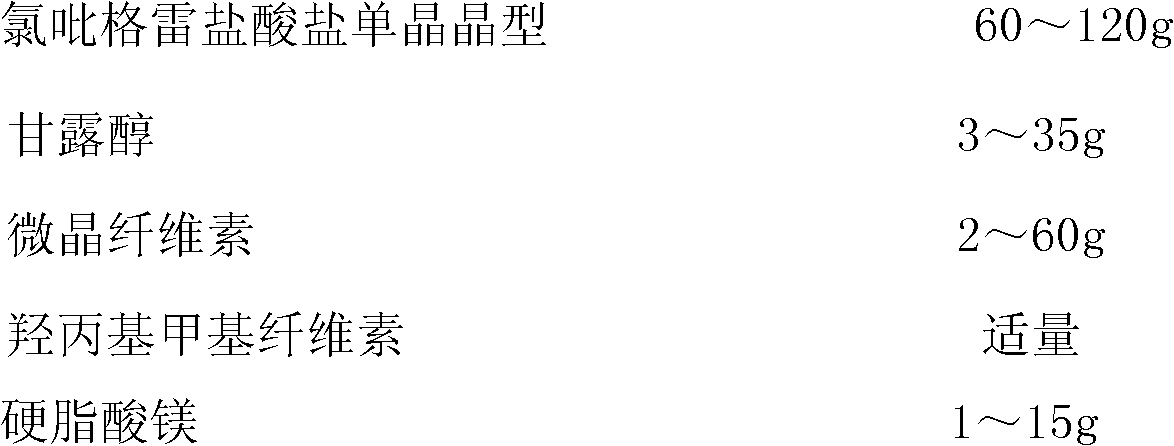

[0025] Embodiment 3: the pharmaceutical composition of clopidogrel hydrochloride monocrystalline form

[0026]

[0027]

[0028] Preparation:

[0029] Weigh the single crystal form of clopidogrel hydrochloride according to the prescription amount and pulverize it through a 120-mesh sieve. Polyethylene glycol 6000 and silicon dioxide are respectively passed through a 100-mesh sieve, and mannitol, microcrystalline cellulose, and hydroxypropyl cellulose are respectively passed through a 80-mesh sieve; the polyethylene glycol 6000, microcrystalline cellulose and clopidogrel hydrochloride, Mannitol and hydroxypropyl cellulose were mixed uniformly by equal amount addition method, mixed for 10 minutes, dry-rolled and granulated, and the granules between 24 and 60 mesh were selected. Calculation of granule yield, silicon dioxide, mixing for about 15 minutes; tableting, film-coating.

[0030] After testing, the average dissolution rate in 30 minutes is:

[0031] seria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com