Square cross-section jacking-pipe tunneling machine

A technology of pipe jacking machine and square section, which can be used in earth-moving drilling, mining equipment, tunnels, etc., and can solve the problems of difficult construction and large resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

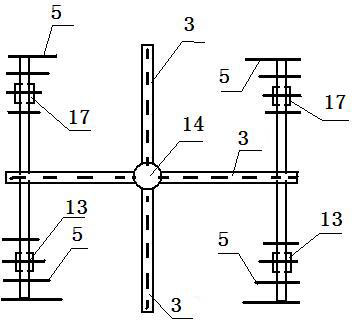

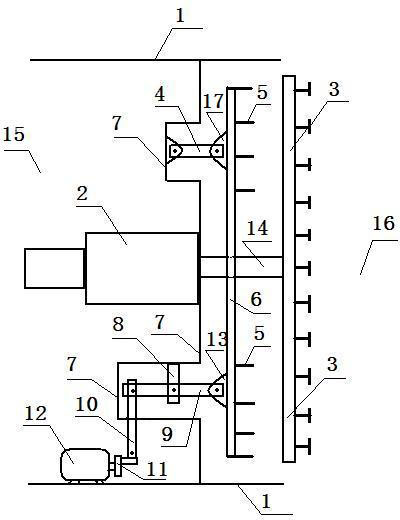

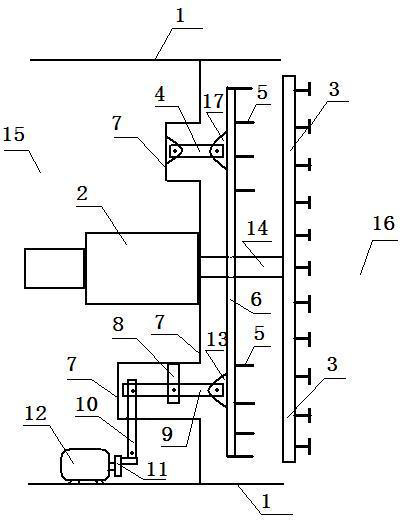

[0012] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment comprises the square casing 1 of square cross-section pipe jacking, and compartment plate 7 separates jacking pipe into operating compartment 15 and soil storehouse 16, and main motor 2, auxiliary motor 12 are provided with In the operating cabin, the main cutter head 3, the auxiliary cutter body 6 and the cutting tool 5 and other cutting mechanisms are set in the soil bin. The main motor is connected to the main cutter head 3 through the main shaft 14, and the auxiliary motor 12 is connected to the main cutter head 3 through the bell crank 11 and the connecting rod C10. On the left end of the connecting rod B9, the right end of the connecting rod B9 is pinned to the support seat A13, the middle pin of the connecting rod B9 is connected to the support rod 8, and the support rod 8 is fixed to the sub-compartment plate 7, and the left end of the connecting rod A4 is pinned to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap