Hidden crack defect tester

A tester, defect technology, applied in the direction of optical testing flaws/defects, etc., can solve the problem of infrared imager inspection needing to adjust the position, etc., to achieve the effect of easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

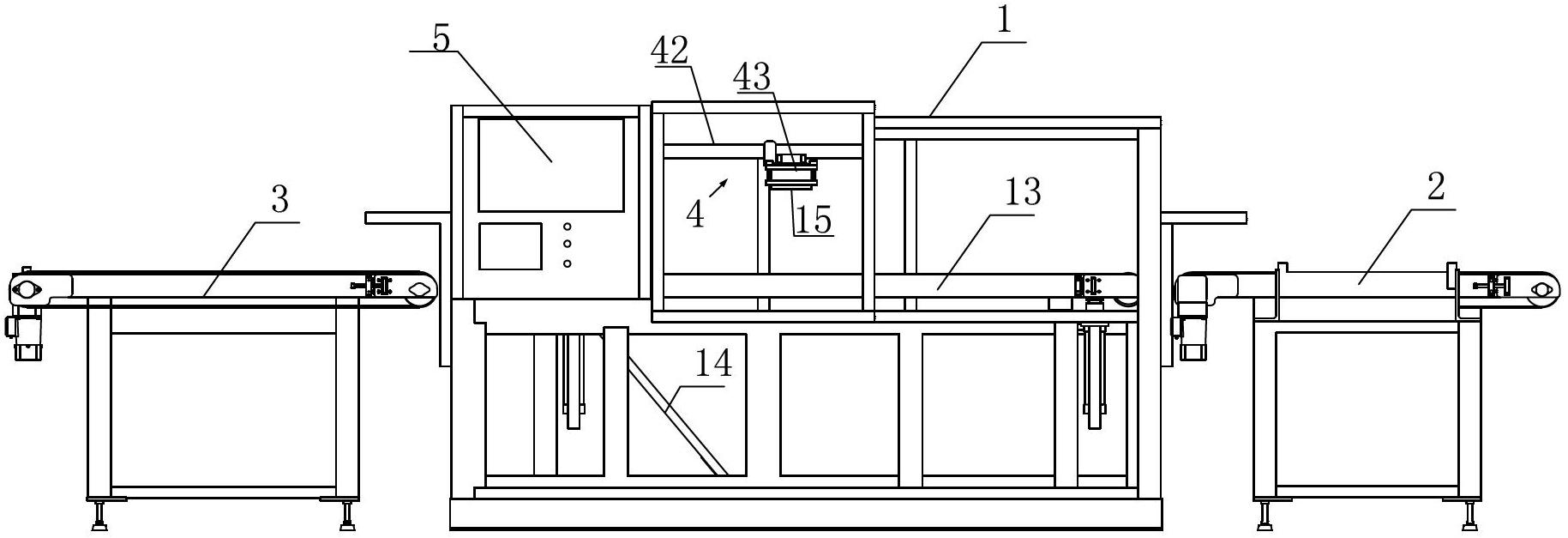

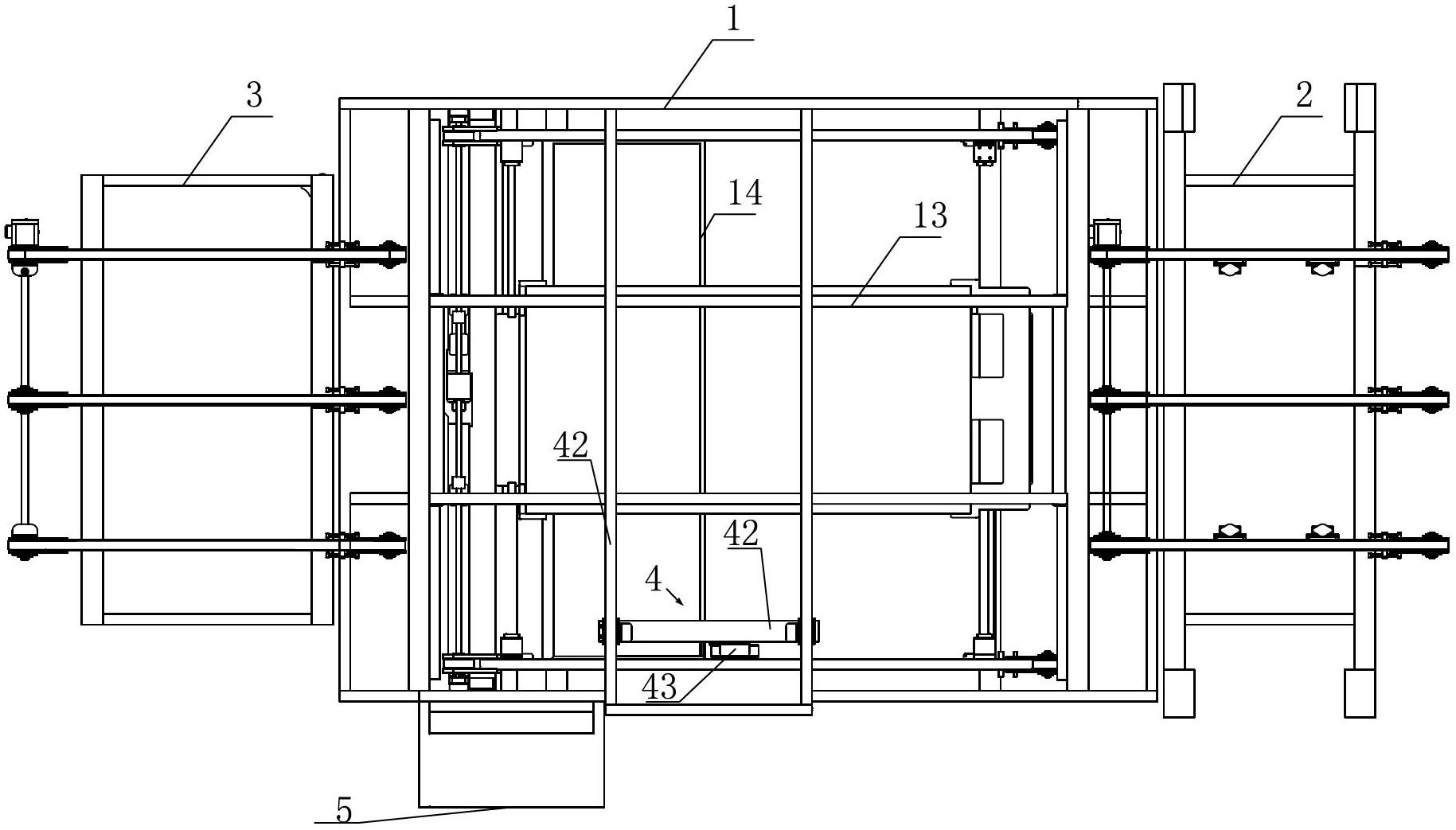

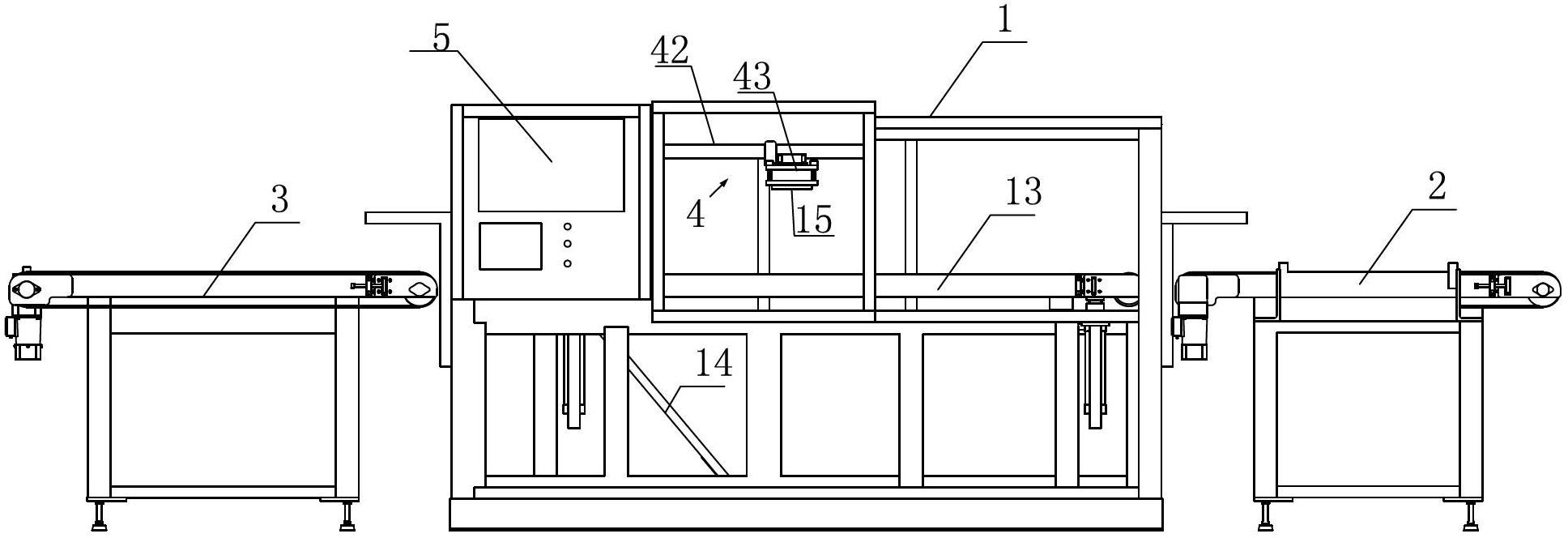

[0015] Below in conjunction with accompanying drawing, preferred specific embodiment of the present invention is described:

[0016] The hidden crack defect tester includes a cabinet-type detector body 1 with an inlet and an outlet, a feeding conveyor 2 arranged outside the inlet for transporting battery panels into the detector body 1, and a feed conveyor 2 arranged outside the outlet. The discharge conveyor 3 for conveying the battery board out of the detector body 1 .

[0017] The entrance and exit are set on the opposite sides of the detector body 1, and the detector body 1 also includes a conveyor belt arranged inside the detector body 1 and connected to the feeding conveyor 2 and the discharge conveyor 3. The middle conveyor 13 on the same horizontal plane, the reflector 14 installed under the conveyor belt of the middle conveyor 13, the infrared imager 15 arranged in the side wall of the detector body 1, and the reflector 14 is obliquely arranged on the detector b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com