Calibration method and angle measuring method for an angle measuring device, and angle measuring device

A technology of angle measurement and calibration method, which is applied in the direction of measuring devices, using electric/magnetic devices to transfer sensing components, instruments, etc., which can solve the problems of no recalibration, complicated calibration, and difficult external positioning of sensors with high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

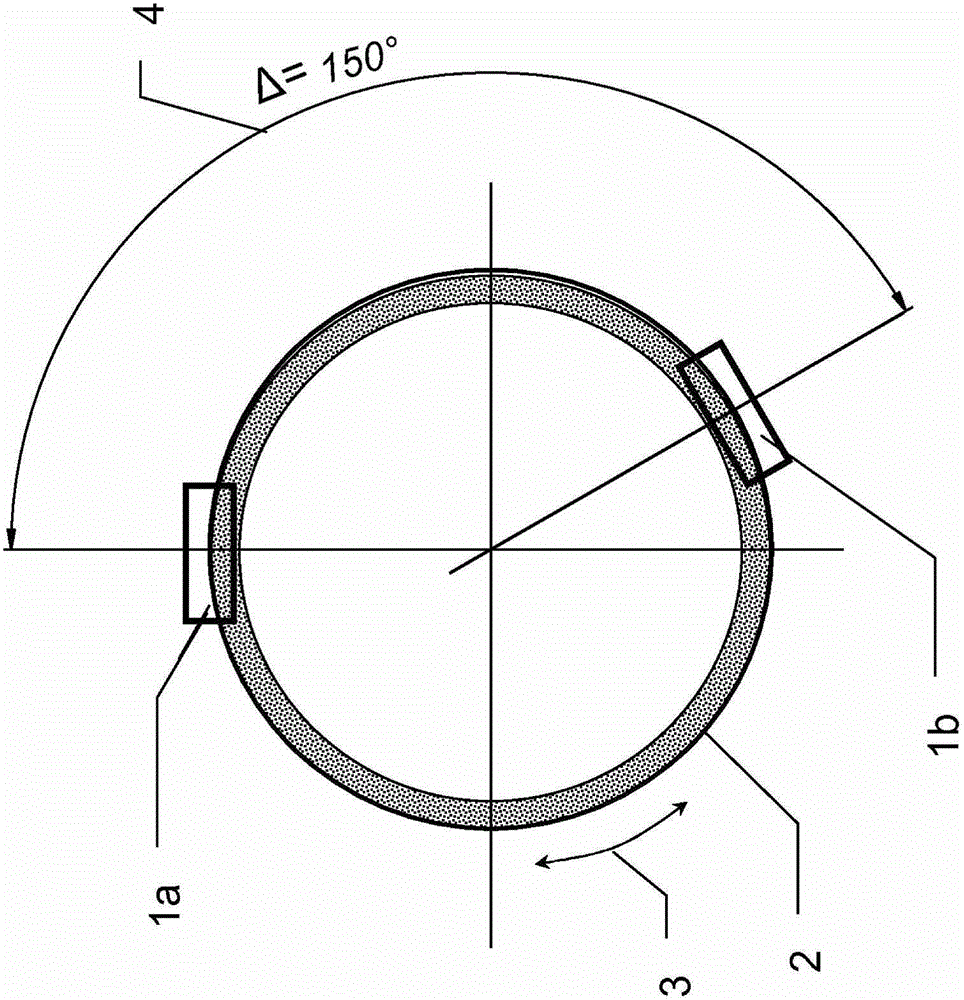

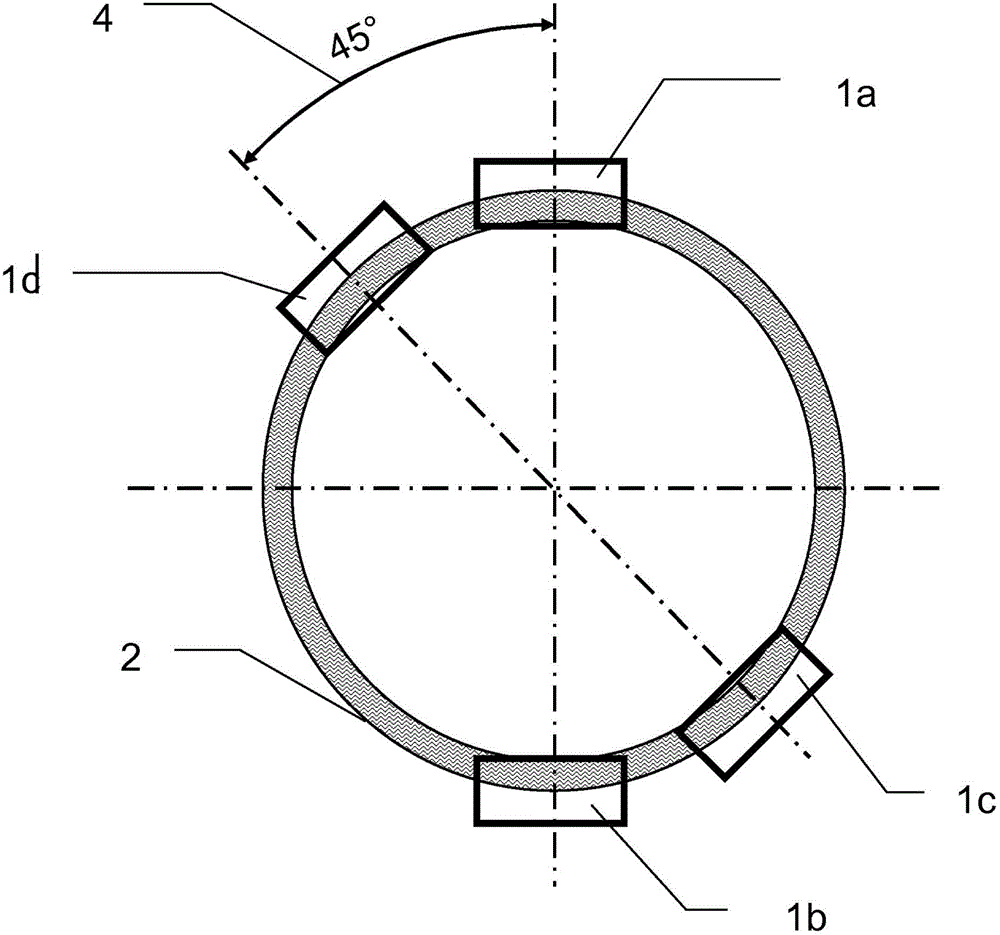

[0095] exist Figure 1a A possible embodiment of the angle measuring system according to the invention can be seen in a schematic diagram.

[0096] An angle measuring system 7 has:

[0097] ■Coding carrier 2 with absolute position coding,

[0098] ■ at least two read heads 1a, 1b, which have a fixed, known angular position 4, which have an angular distance relative to each other, in particular greater than 50 degrees, for example 70 degrees to 180 degrees, preferably 140 degrees degrees to 170 degrees, for example 150 degrees, and the read heads are respectively adapted to at least partially detect the position code, so that the absolute angular position value of the corresponding read head 1a, 1b relative to the code carrier 2 can be determined, and wherein the code carrier 2 can be rotated relative to the read head 1a, 1b and thus can occupy different angular positions 3 of the code carrier 2 relative to the read head 1a, 1b, and

[0099] ■ An analysis unit (not shown) for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com