Combined piping guide filtering device

A combined and piping technology, which is applied in water conservancy projects, sea area projects, construction, etc., can solve the problems of long preparation and construction period, frequent operation times, and large overall weight, and overcome the problems of large laying area, convenient and fast operation, and improved The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in conjunction with accompanying drawing and specific embodiment:

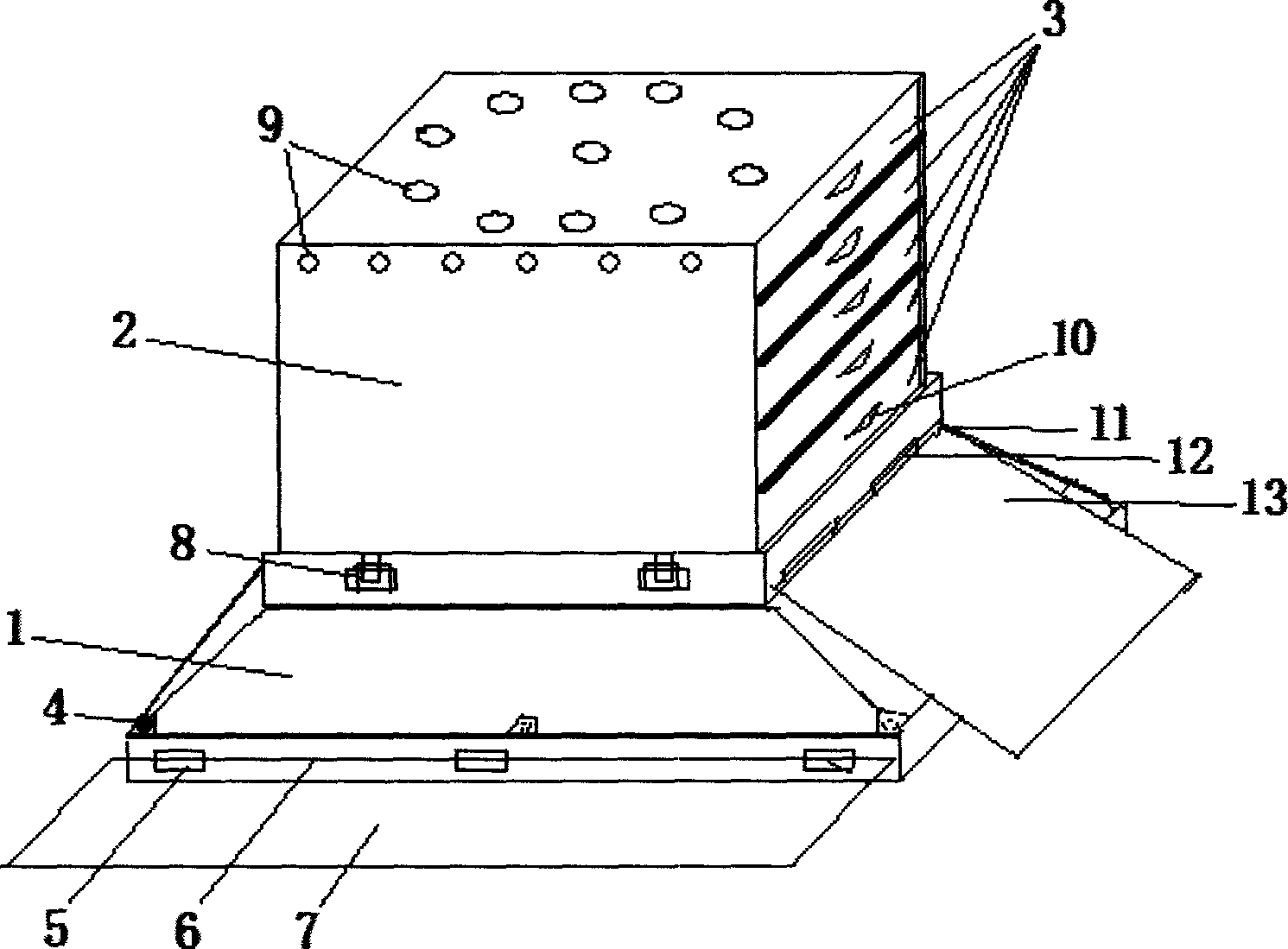

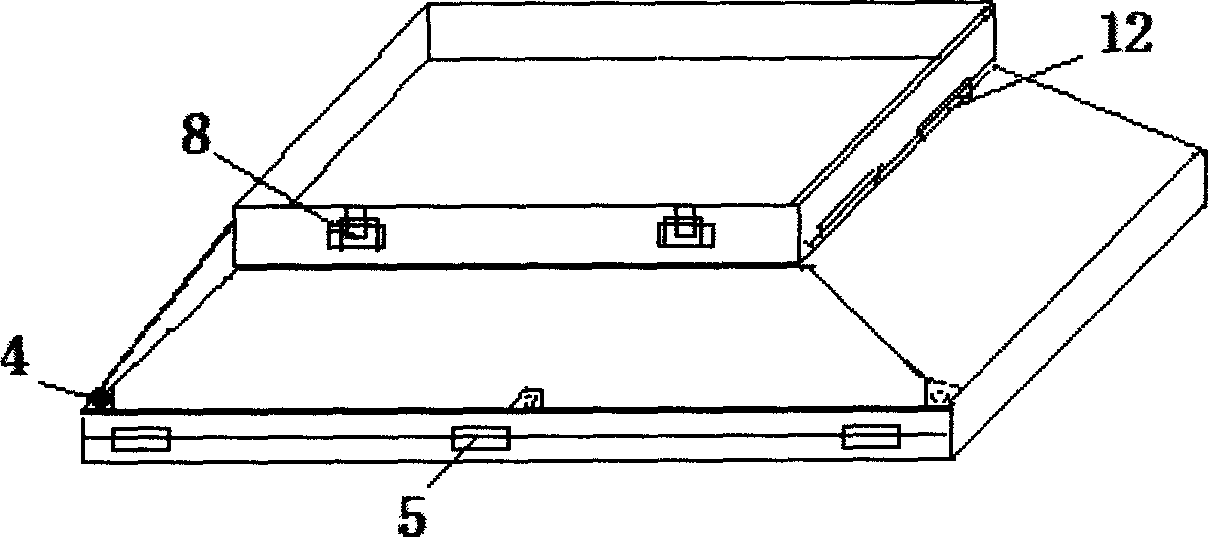

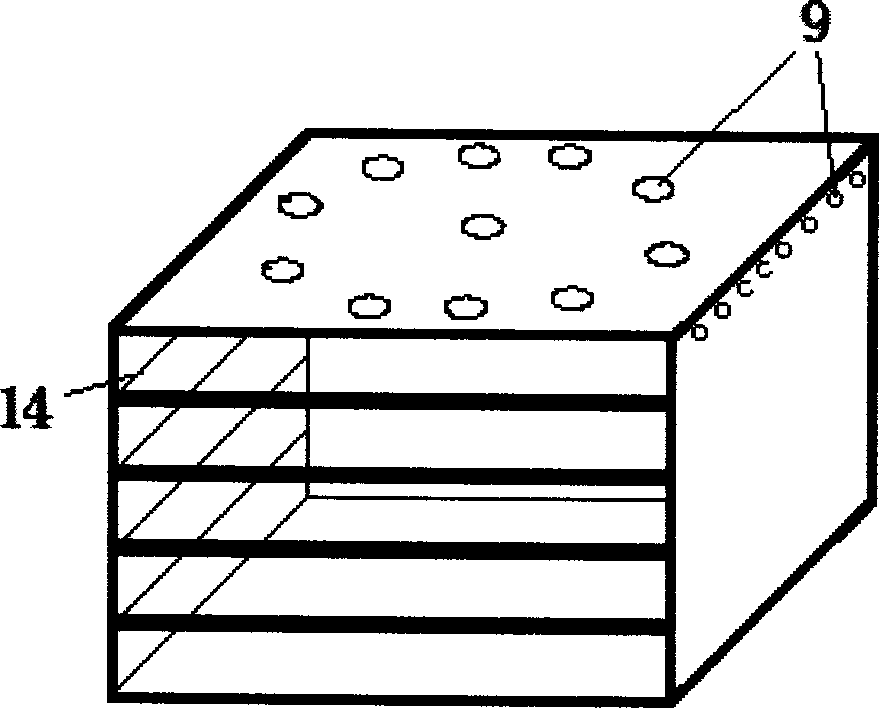

[0025] Such as figure 1 As shown, a combined piping filter guide device includes a support base 1, a filter box frame 2 and a filter insert 3; the support base 1 is a cavity structure, and the filter box frame 2 is arranged in the cavity structure The top of the support base 1, the filter box frame 2 is also a cavity structure, and the filter box frame 2 is a box structure with a bottom surface and a side opening, the filter box frame 2 of the cavity structure and the support base 1 Plug-in connection, the filter insert 3 is inserted into the filter box frame 2 through the side opening of the filter box frame 2; The side opening is set to seal the sealing door 13 of the filter insert; Figure 5 , is provided with load-bearing plate 7; Described load-bearing plate 7 is movably connected with support base 1, has bearing pin sleeve I5 on described load-bearing plate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com