Wind resisting device for roller shutter door

A technology of rolling doors and reels, which is applied in the field of doors and windows, can solve the problems of bending deformation of rolling doors, damage of rolling doors, local gaps, etc., and achieve the effect of moving balance, good wind resistance performance and stable wind resistance components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

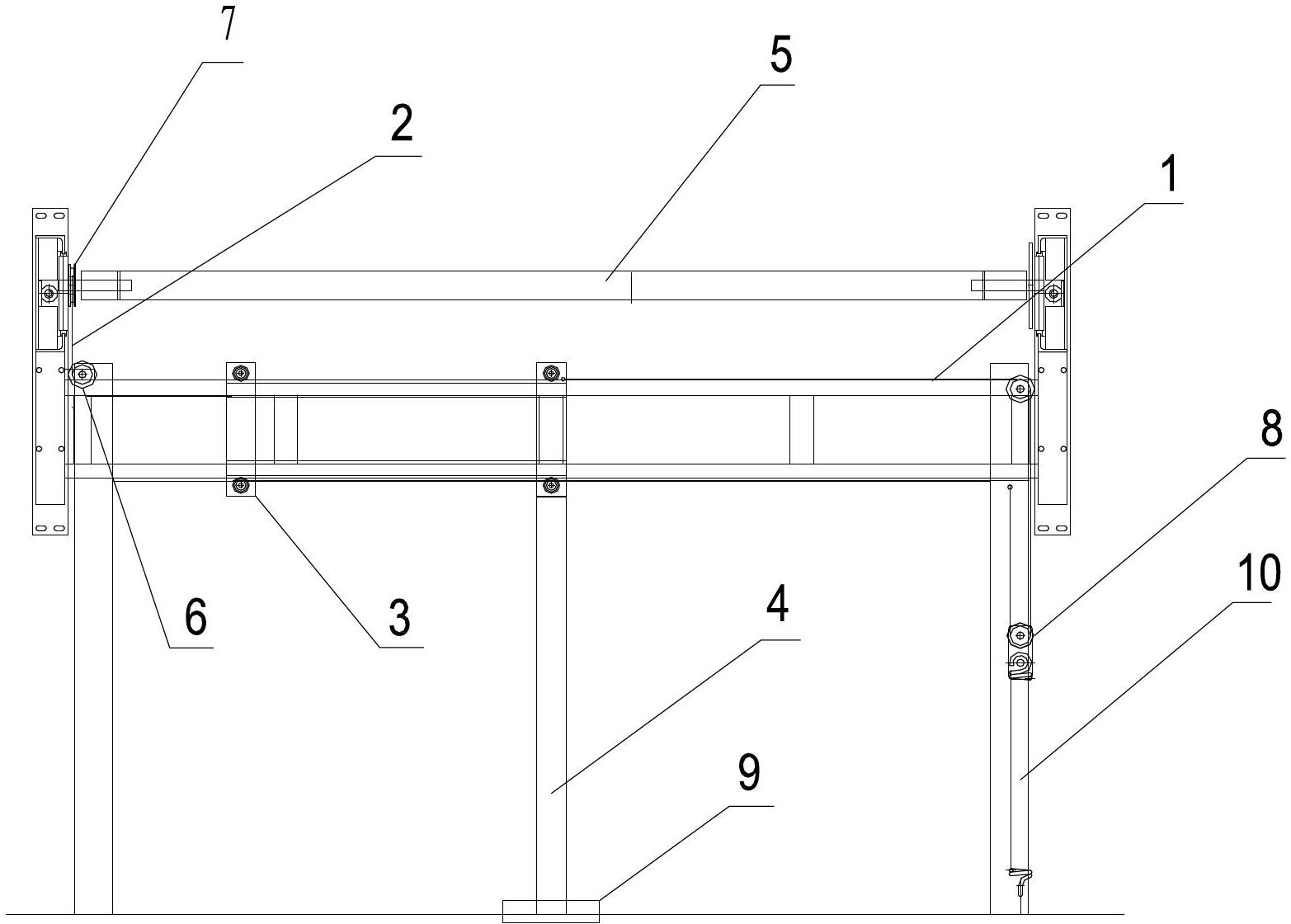

[0030] Such as figure 1 As shown, a wind-resistant device for a rolling door includes a bracket 1, a traction assembly 2, a walking assembly 3 and a wind-resistant assembly 4;

[0031] The support 1 is installed horizontally on the side of the rolling shutter door close to the inside of the door, under the reel 5, and the first end of the support 1 is equipped with a fixed pulley 6;

[0032] The traction assembly 2 is generally a flexible assembly such as a rope or a chain. One end of the traction assembly 2 is wound and fixed on the reel 5, and the other end of the traction assembly 2 is fixed on the walking assembly 3. The traction assembly 2 Across the fixed pulley 6, the preferred winding and fixing method is to fixedly install a reel 7 on one end of the reel 5, and a corresponding guide groove is provided on the reel 7, and the traction assembly 2 is wound on the On the reel 7, when the shutter door is opened or closed, the reel 5 rotates, and the traction assembly 2 is ...

Embodiment 2

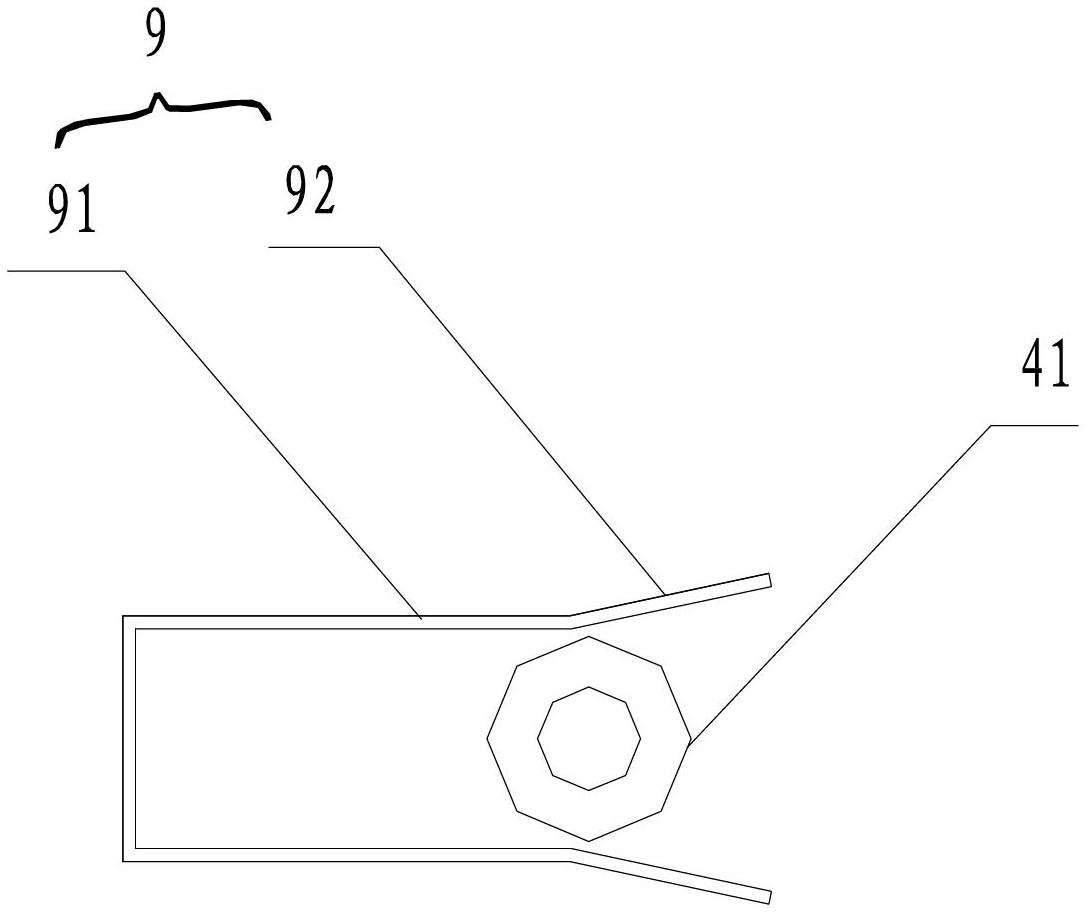

[0037] combine figure 1 and figure 2 Because the industrial rolling shutter door is relatively wide and relatively high, the wind-resistant assembly 4 is generally relatively long. When the walking assembly 3 moves, the movement of the wind-resistant assembly 4 is often not accurate enough. On the basis of 1, another embodiment is provided: a walking wheel 41 is provided under the wind-resistant assembly 4, and the walking wheel 41 performs a walking function and supports the wind-resistant assembly 4. In addition, Positioning guide rail grooves 9 are installed on the ground corresponding to the positions of the wind resistance components 4, and the two sides of the positioning guide rail grooves 9 are connected by a horizontal section 91 and an inclined section 92. The angle of the outside of the guide rail groove is 135-180 degrees. At this time, due to wind or other reasons, when the wind-resistant assembly 4 is not kept in a vertical state, the diameter of the guide groo...

Embodiment 3

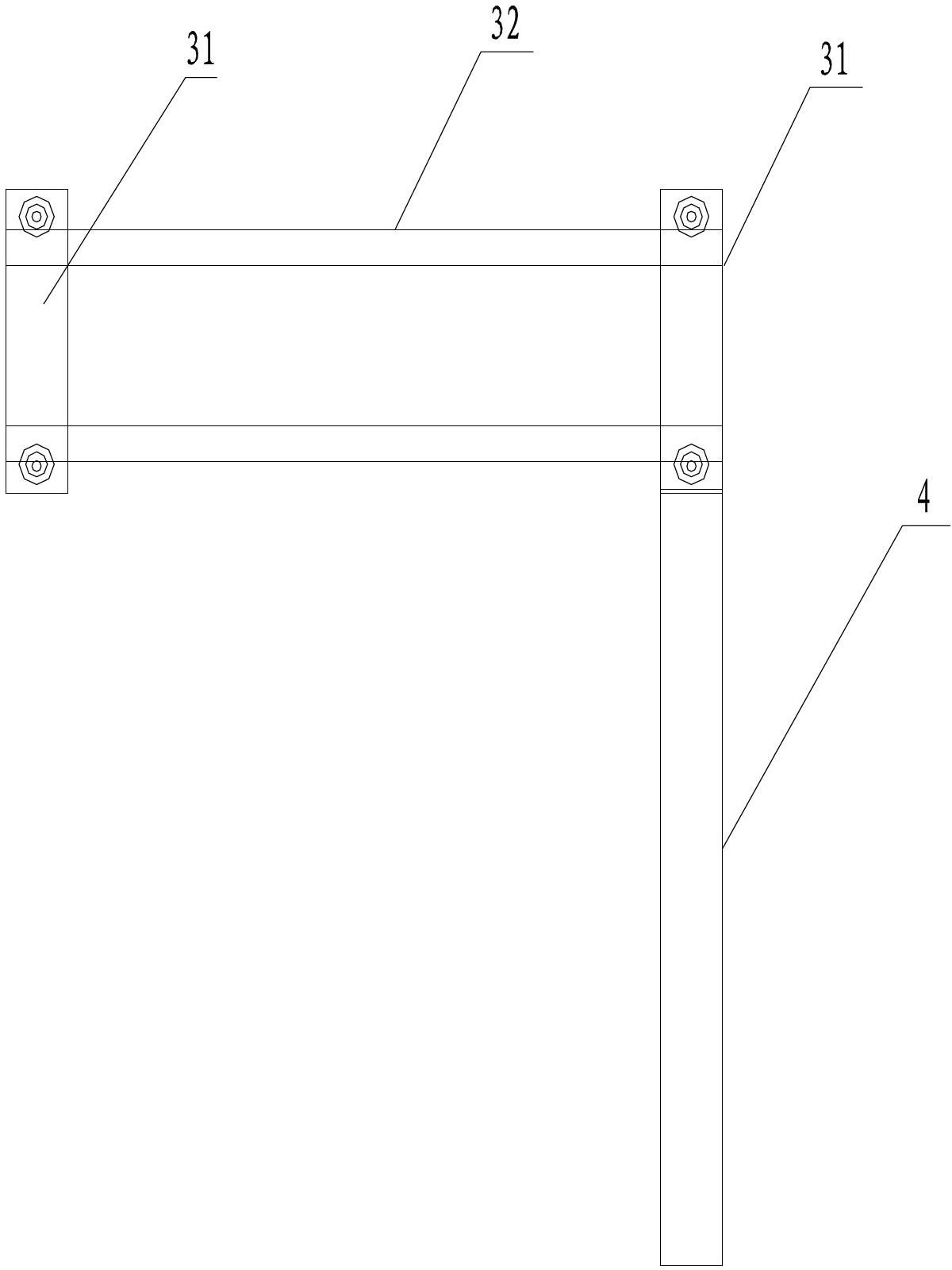

[0039] combine Figure 1 to Figure 4, in order to make the walking assembly 3 more stable during the movement, on the basis of Embodiment 1 or Embodiment 2, the walking assembly 3 preferably includes two groups of walking units 31, and the walking units include two slats 311, so The upper and lower ends of the two slats are respectively connected by the upper connecting shaft 312 and the lower connecting shaft 313, and the positions of the upper connecting shaft 312 and the lower connecting shaft 313 near the two slats 311 are respectively equipped with rollers 314, so The roller 314 of the upper connecting shaft 312 is in contact with the upper surface of the bracket 1, the roller 314 of the lower connecting shaft 313 is in contact with the lower surface of the bracket 1, and the wind-resistant assembly 4 is fixedly connected to one of them. Above the slats, the traction assembly 2 is fixedly connected to the traveling unit 31 , and the two traveling units 31 are connected th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com