Extrusion device for tread

A technology of extrusion device and tread, which is applied in tires, applications, household appliances, etc., to avoid movement, save time, and facilitate transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

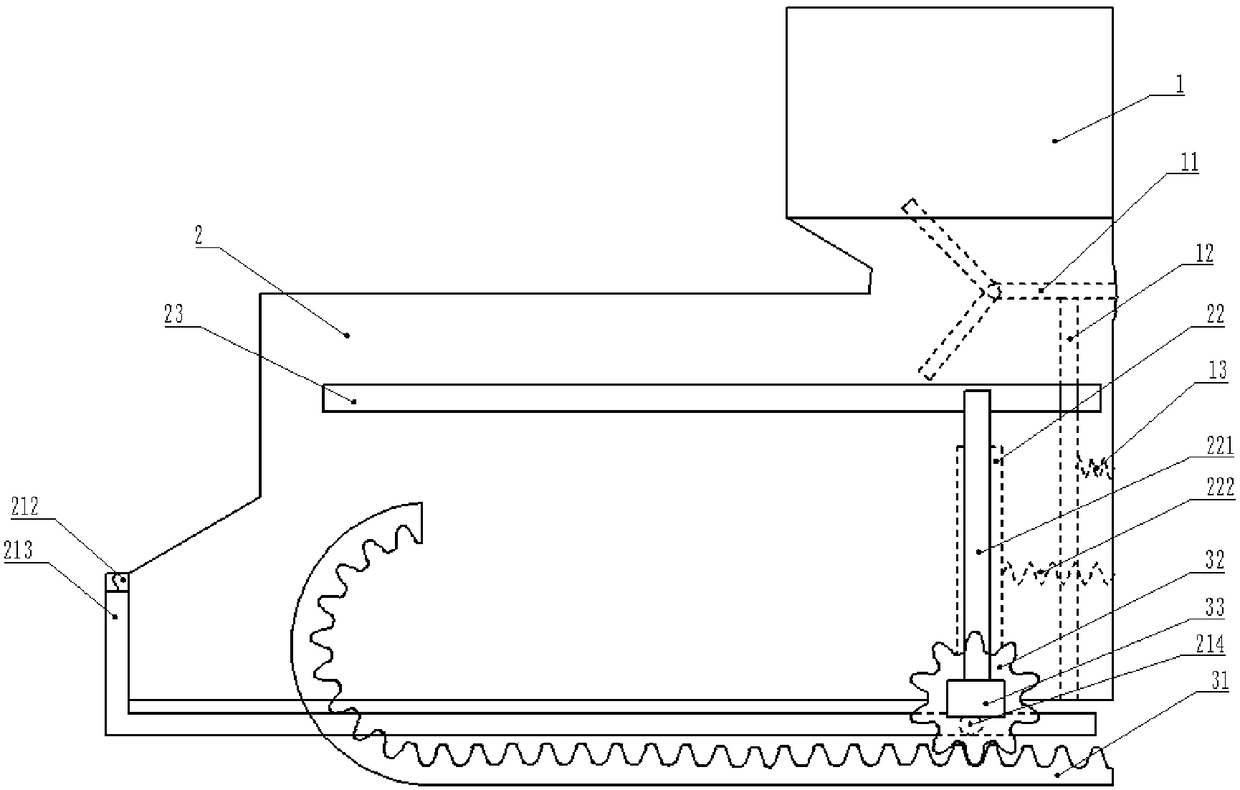

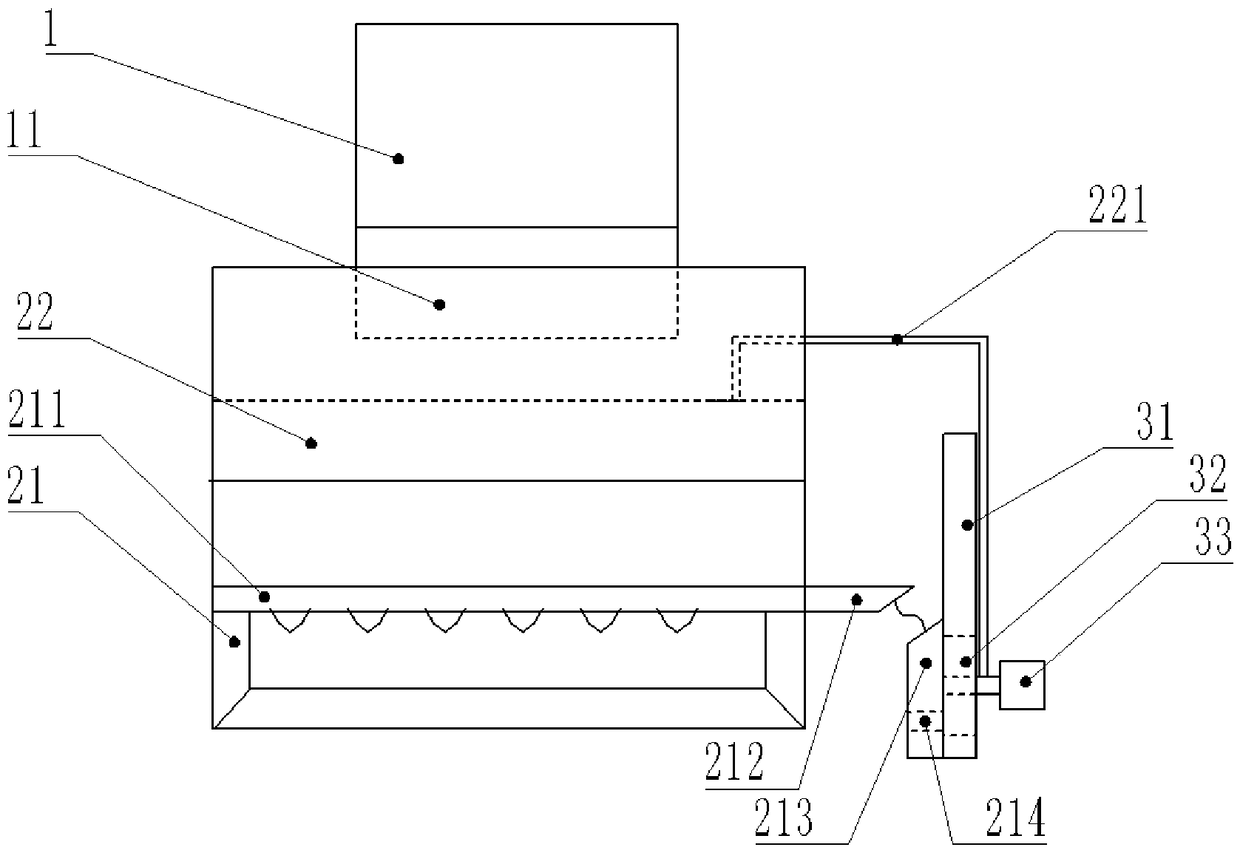

[0024] The reference numerals in the drawings of the specification include: the unloading mechanism 1, the baffle plate 11, the limit block 12, the second elastic member 13, the left mold 21, the pattern part 211, the right mold 22, the first elastic member 222, The first wedge 212 , the second wedge 213 , the slider 214 , the connecting rod 221 , the sliding hole 23 , the rack 31 , the gear 32 , and the stepper motor 33 .

[0025] The embodiment is basically as figure 1 and figure 2 Shown: an extrusion device for treads, including a material-feeding mechanism 1 equipped with raw materials, a molding die and a laterally arranged ejection mechanism, the lower end of the material-cutting mechanism 1 is connected to the ejection mechanism. Ejecting mechanism comprises releasing housing, and the left end of releasing housing is provided with outlet, and molding die comprises left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com