A Ligand-Free Atom Transfer Radical Polymerization Method Based on Elemental Metal Interaction

A metal element, atom transfer technology, applied in the field of ligand-free atom transfer radical polymerization and atom transfer radical polymerization, can solve the problems of high price and high toxicity, and achieve balanced movement, good control, and reduce damage. degree and effect of response cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

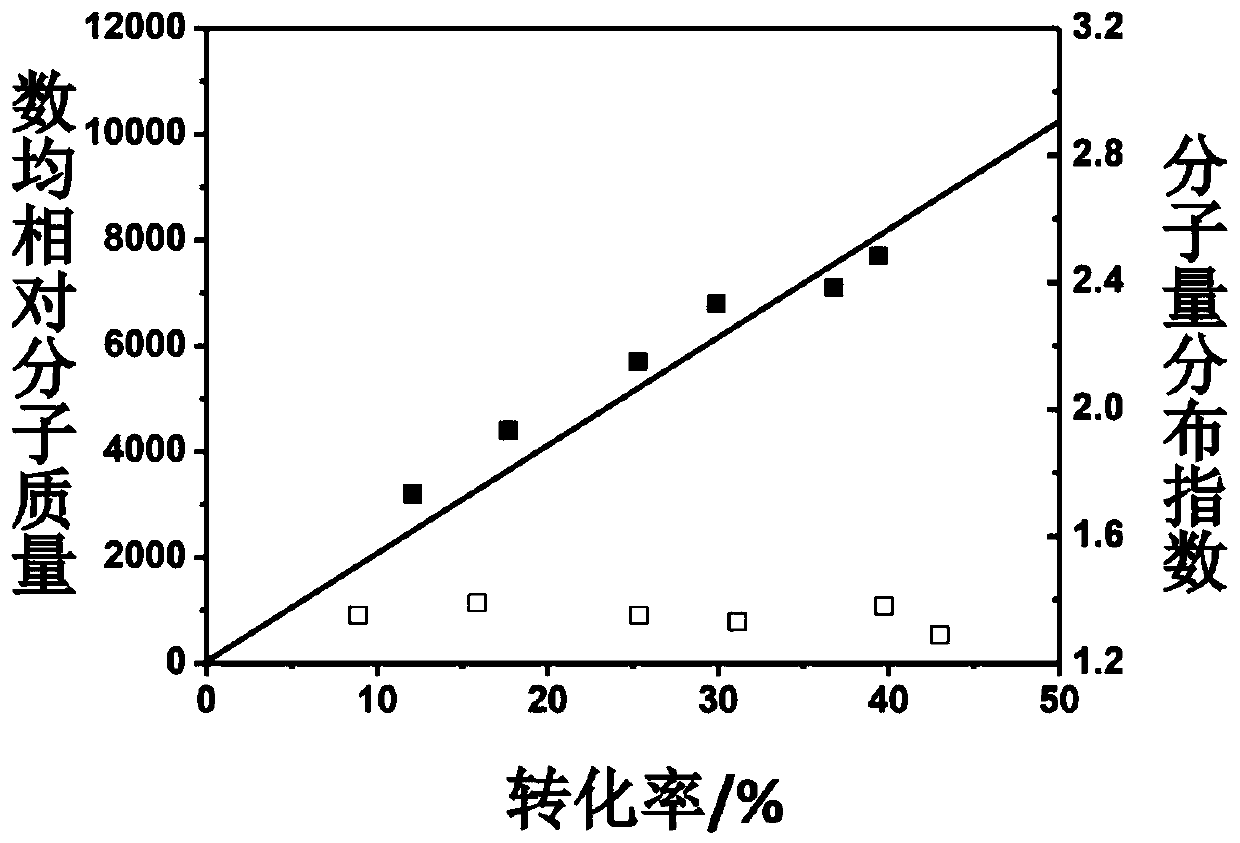

[0048] After purification of methyl methacrylate monomer, ethyl 2-bromoisobutyrate halogenated hydrocarbon and micron iron powder, the polymerization reaction components are prepared, methyl methacrylate, ethyl 2-bromoisobutyrate, bromine The molar ratio of ferrous oxide (low-valence state transition metal catalyst) to metal iron powder is 200:1:1:0.5. The preparation process is as follows: weigh 0.061 grams of ferrous bromide and 0.0079 grams of iron powder in the glove box and put them into an eggplant-shaped bottle, add 6 milliliters of methyl methacrylate monomer into the eggplant-shaped bottle, and stir magnetically for 20 minutes. , and then added 37.7 microliters of ethyl 2-bromoisobutyrate, and continued to stir for 2 minutes to obtain a pre-reaction mixture.

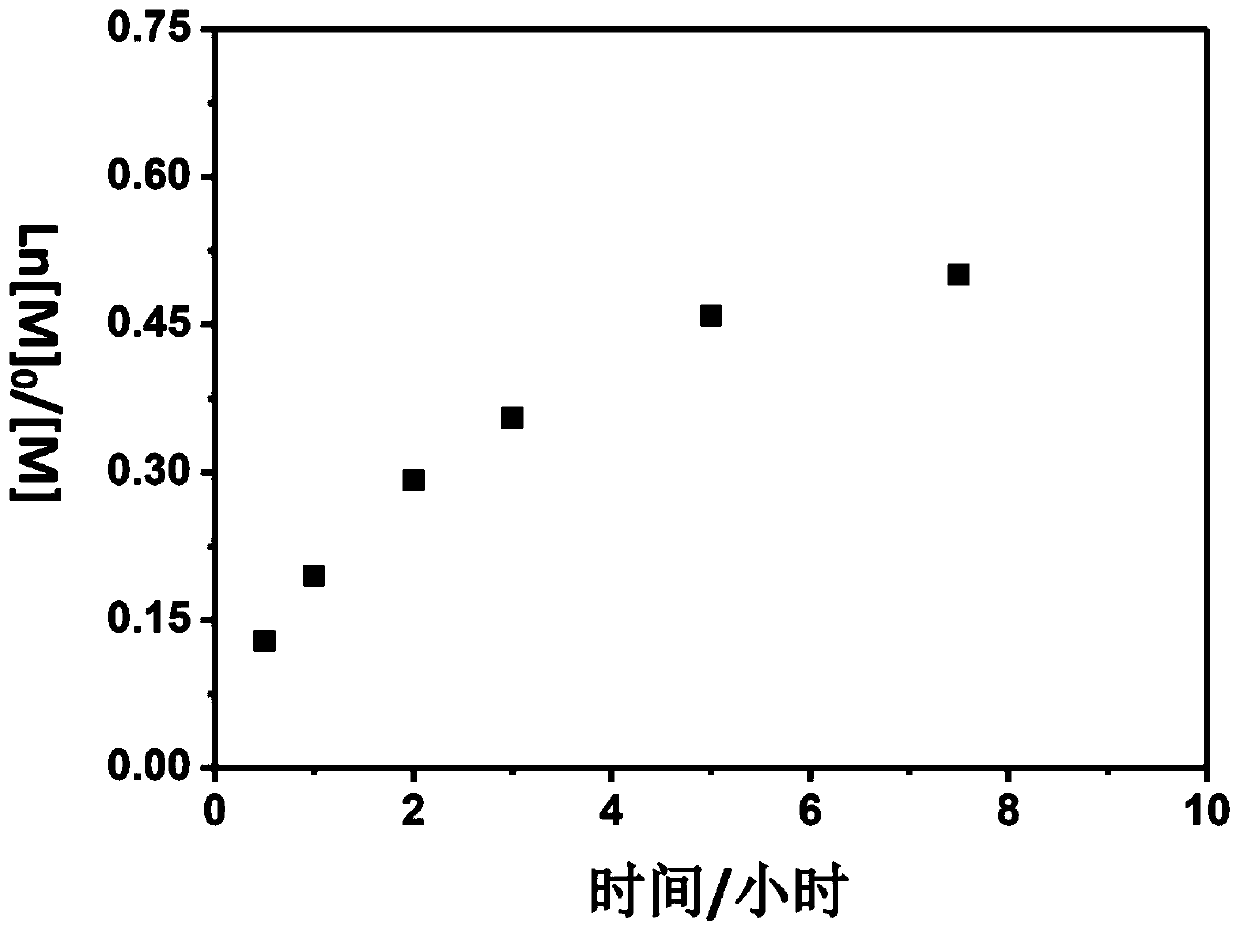

[0049] Transfer the pre-reaction mixture in the eggplant-shaped bottle to the heating device, and control the reaction temperature to 60°C; after the polymerization reaction reaches the predetermined reaction ti...

Embodiment 2

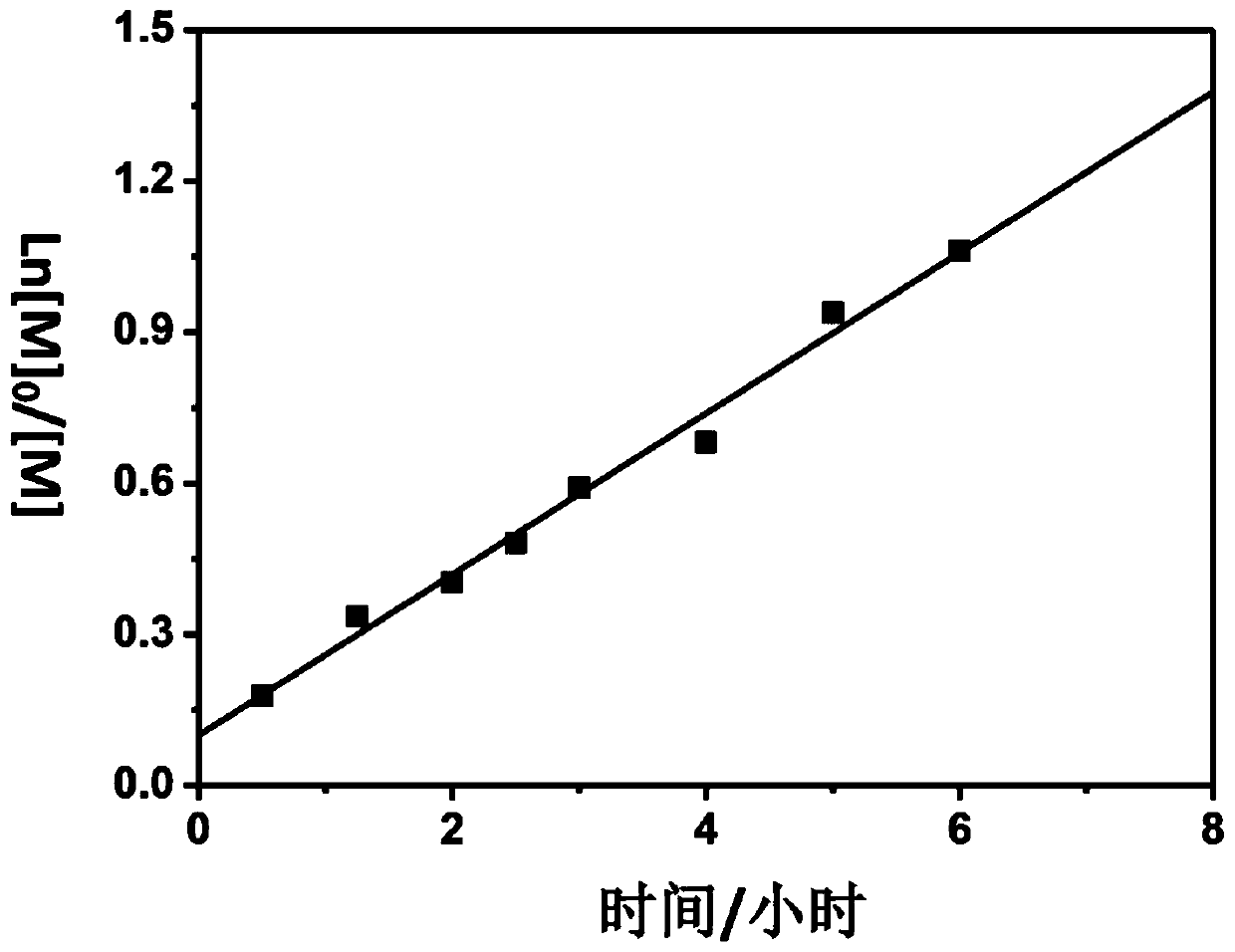

[0051] After purification of methyl methacrylate monomer, ethyl 2-bromophenylacetate, halogenated hydrocarbons, and silver nanowires, the polymerization reaction components were prepared, methyl methacrylate, ethyl 2-bromophenylacetate, bromine The molar ratio of ferrous oxide (low-valence state transition metal catalyst) to nano-silver wire is 200:1:1:0.25. The preparation process is as follows: Weigh 0.061 g of ferrous bromide and 0.0075 g of nano-silver wire into an eggplant-shaped bottle in a glove box, add 6 ml of methyl methacrylate monomer into the eggplant-shaped bottle, and stir magnetically for 20 minutes Then, 49.5 microliters of ethyl 2-bromophenylacetate was added, and the stirring was continued for 2 minutes to obtain a pre-reaction mixture.

[0052] Transfer the pre-reaction mixture in the eggplant-shaped bottle to the heating device, and control the reaction temperature to 60°C; after the polymerization reaction reaches the predetermined reaction time interval,...

Embodiment 3

[0055] After purification of methyl methacrylate monomer, ethyl 2-bromophenylacetate halogenated hydrocarbons and silver nanowires, the polymerization reaction components were prepared, methyl methacrylate, ethyl 2-bromophenylacetate, bromine The molar ratio of ferrous oxide (low-valence state transition metal catalyst) to nano-silver wire is 200:1:1:0.1. The preparation process is as follows: Weigh 0.061 grams of ferric bromide and 0.003 grams of nano-silver wires into an eggplant-shaped bottle in a glove box, add 6 milliliters of methyl methacrylate monomer into the eggplant-shaped bottle, and stir magnetically for 20 minutes. , and then added 49.5 microliters of ethyl 2-bromophenylacetate, and continued to stir for 2 minutes to obtain a pre-reaction mixture.

[0056] Transfer the pre-reaction mixture in the eggplant-shaped bottle to the heating device, and control the reaction temperature to 60°C. After the polymerization reaction reaches the predetermined reaction time int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com