Method for producing yarn-dyed fabric of different shades

A manufacturing method and technology of yarn-dyed fabric, which is applied in the field of yarn-dyed fabric manufacturing, can solve problems such as foaming, and achieve the effect of solving the foaming of the cloth surface after washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

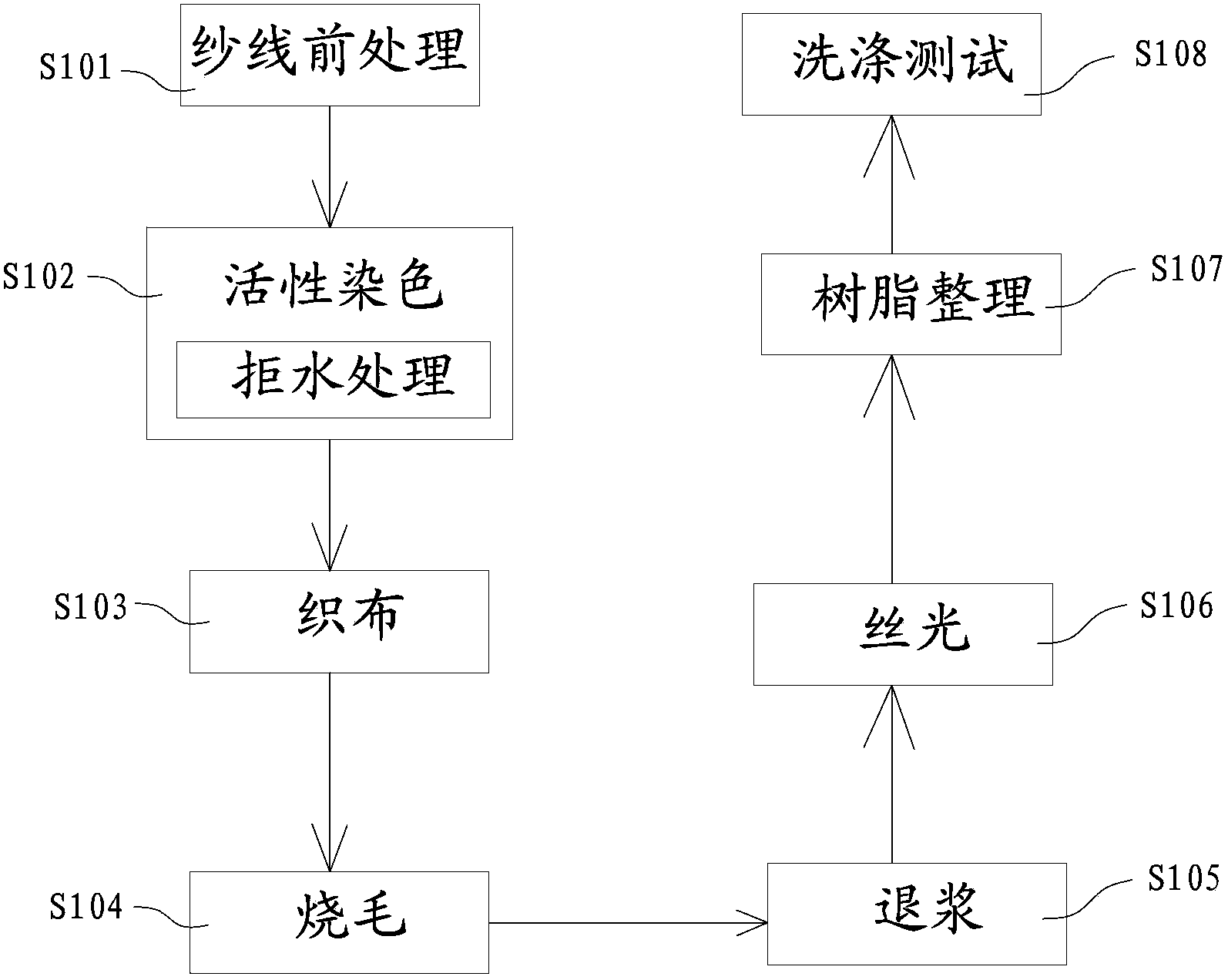

[0017] Such as figure 1 Shown, a kind of manufacturing method of the yarn-dyed cloth of alternate colors of dark and light, comprises the following steps:

[0018] Step S101, performing pre-processing on the yarn.

[0019] Step S102, reactively dyeing the yarn. After the dyeing process is completed, water repellent and acetic acid are added to the dye vat for light-colored warp yarn. The content is 4g-6g, the amount of acetic acid is 0.1g-0.2g per liter of water, the water temperature in the dyeing vat is 30°C-80°C, try to control the water temperature at 40°C-60°C, preferably 50°C, and the warp yarn Take it out after soaking for 5 minutes to 30 minutes, try to control it for 10 minutes to 20 minutes, preferably only soak for 15 minutes.

[0020] Step S103, weaving cloth, this process is a well-known technology in the prior art, and will not be repeated here.

[0021] Step S104, singeing, this process is a well-known technology in the prior art, and will not be repeated her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com