Roadbed slab non-tensile stress construction method based on combined channel girder

A construction method and technology of combined troughs, which are applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems affecting vehicle traffic under the bridge and the urban environment, high requirements for hoisting and transportation capacity, and difficult layout of structural prestressed beams, etc. problems, to achieve the effect of reducing the amount of on-site work, shortening the construction period, and making the structure light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

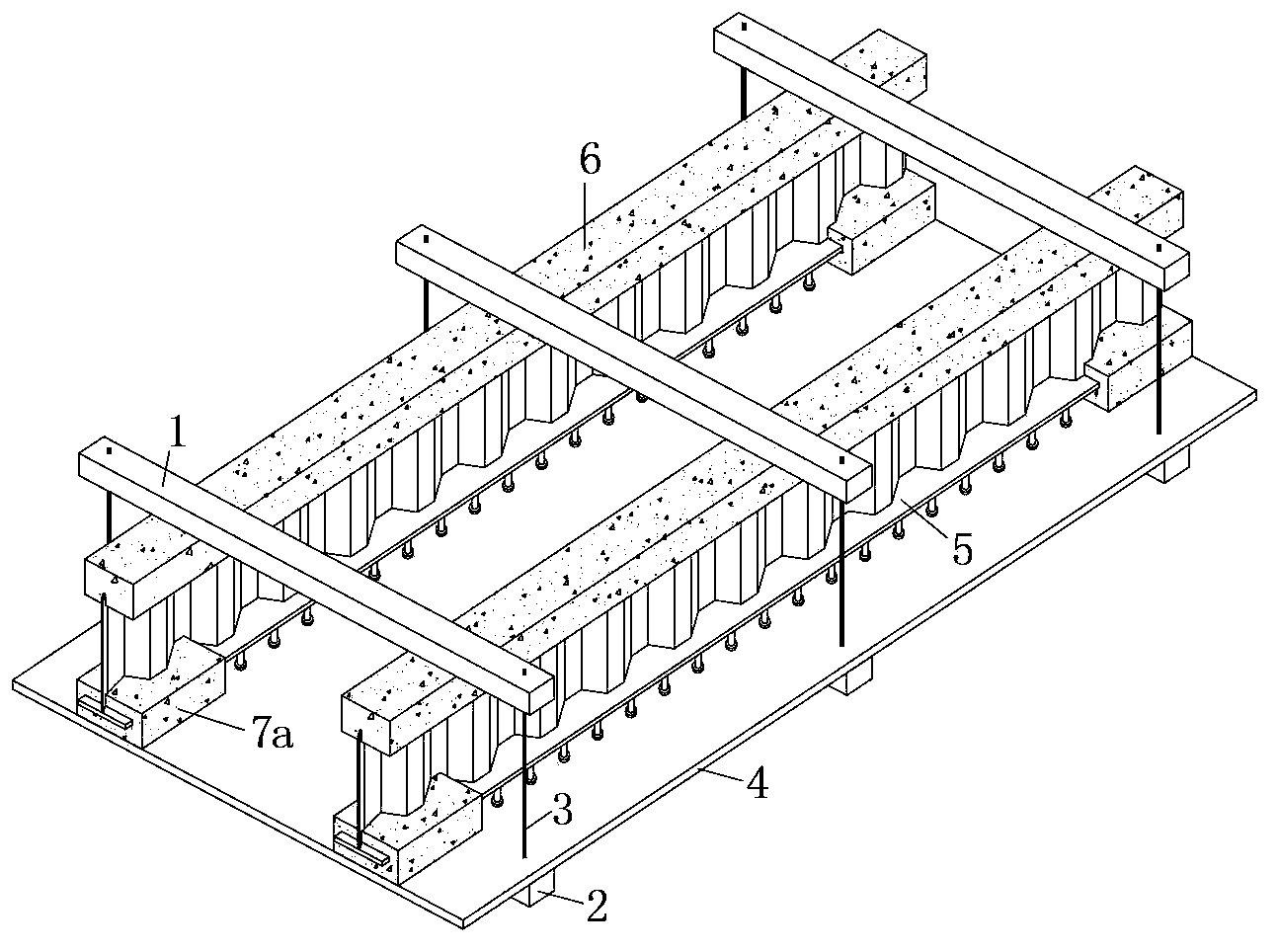

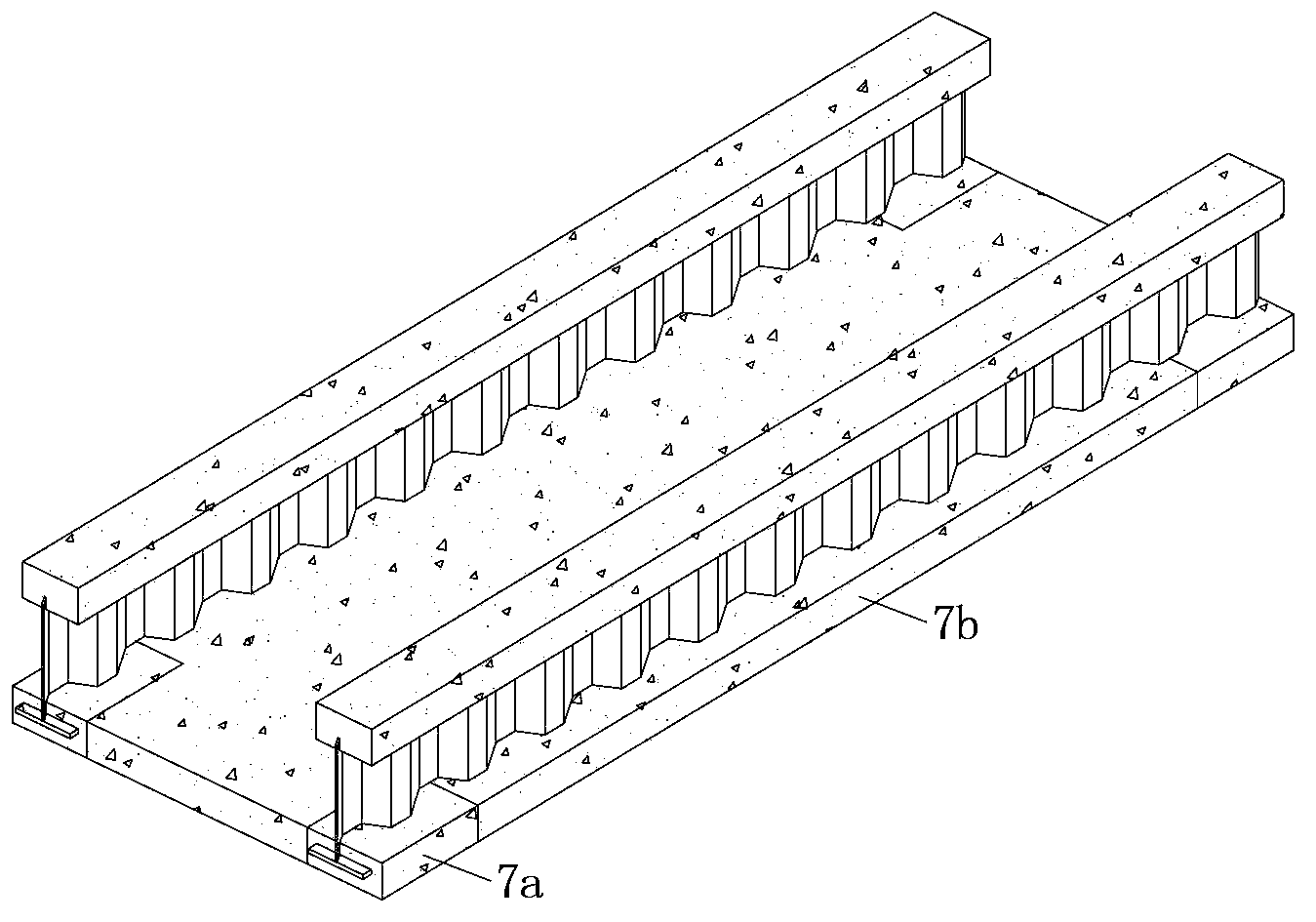

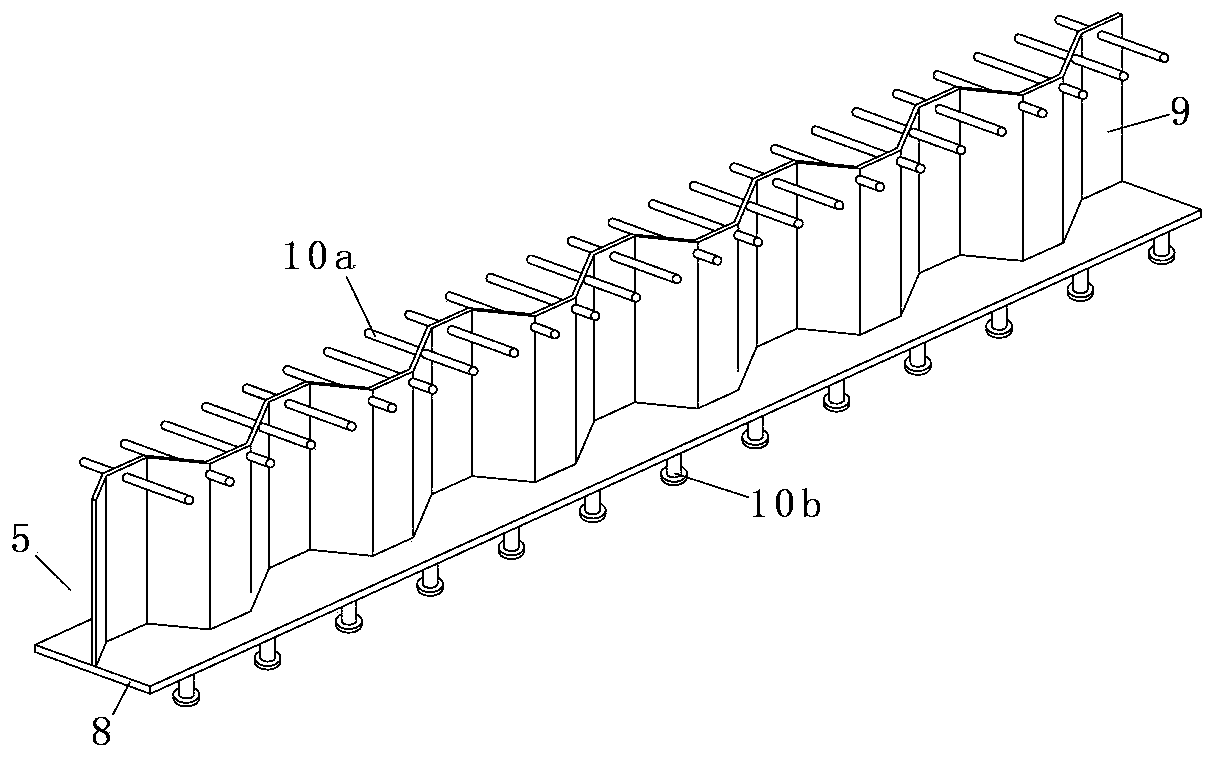

[0025] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The following is attached Figure 1-5 , further describe the implementation process of the present invention:

[0027] A. Steel web 9 is welded on steel bar 8 to form steel girder 5, such as Figure 5 As shown in (a), the cross-sectional size and pre-arch value of the steel bar 8 should be determined according to the structural self-weight of the channel beam; this step can be welded and assembled in the factory; the steel web is a corrugated steel plate or a flat steel plate, of which Corrugated steel plates do not need to be equipped with structural measures to prevent roll instability, while flat steel plates need to be provided with stud shear connectors on the surface, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com