Fabricated cantilever composite structure bridge and construction method thereof

A combined structure and assembled technology, which is applied in erecting/assembling bridges, bridge construction, bridges, etc., can solve problems such as the overall thickness and self-weight of the bridge deck, many cantilever slab supports and formwork, and small prefabricated slabs. , to achieve the effect of reducing cost, facilitating construction and preventing water vapor intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

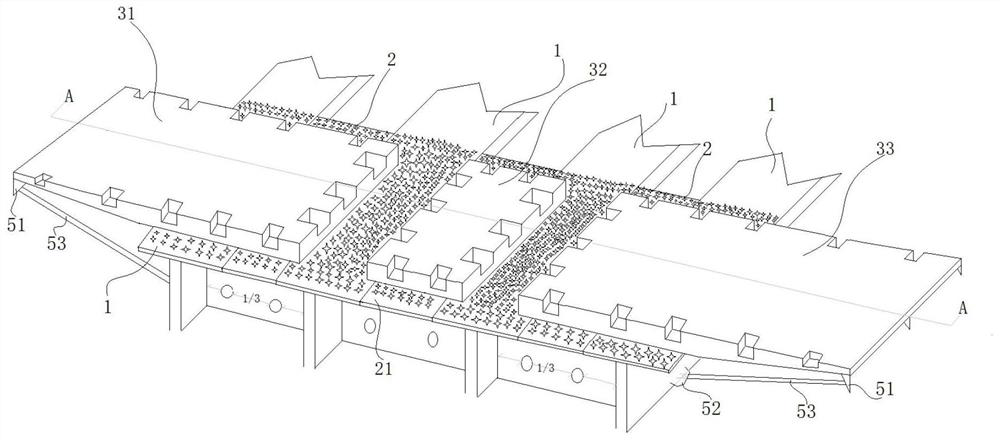

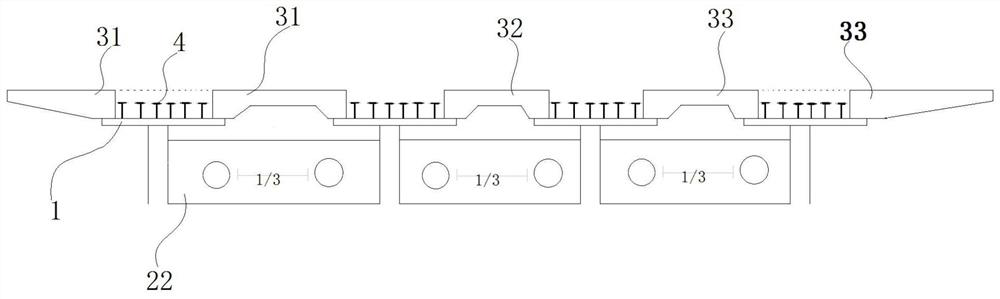

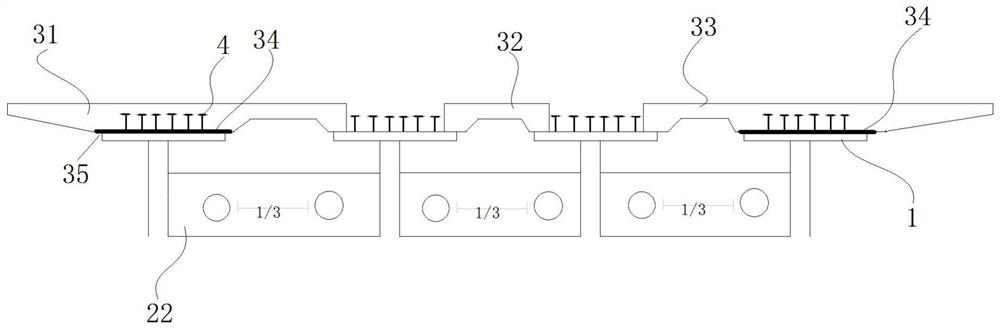

[0039] figure 1 Shown is the three-dimensional structural schematic diagram of the assembled cantilever composite structure bridge of the present invention, the bridge includes a rigid transverse connection system 2, a bridge deck and four or more steel longitudinal girders 1 juxtaposed;

[0040] The bridge deck is a prefabricated composite structure bridge deck with a variable thickness combined section according to the force distribution of the bridge;

[0041] The assembled composite structure bridge deck includes two or more cantilever bridge decks 31, 33 and one or more intermediate bridge decks 32;

[0042] The longitudinal bottoms of the cantilever bridge decks 31 and 33 are preset with longitudinal consolidation parts consolidated with steel longitudinal beams;

[0043] The horizontal connection system 2 horizontally supports the bridge deck of assembled composite structure; the two steel longitudinal girders 1 adjacent on the outside (horizontally parallel) respectiv...

Embodiment 2

[0098] Figure 7 Shown is the flow chart of the construction method of the assembled cantilever composite structure bridge of the present invention, and the method comprises steps:

[0099] S101, prefabricating a prefabricated composite structure bridge deck with a variable thickness combined section according to the force distribution of the bridge, the fabricated composite structure bridge deck includes two or more cantilever bridge decks and one or more intermediate bridge decks, cantilever The longitudinal bottom of the bridge deck is prefabricated with longitudinally consolidated components consolidated with steel longitudinal beams; prefabricated steel longitudinal beams and transverse linkages;

[0100] Specifically:

[0101] Prefabricate the contact surface of the prefabricated composite structure bridge deck with the steel longitudinal girder or the transverse connection as a thick section, and the other non-contact surfaces gradually change from a gradual section to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com