Structure and method of flip chip encapsulation of non-array bumps

A bump and molding technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of thermal expansion, bursting, and slow filling of chips and substrates, and achieve the effect of slowing down the speed of mold flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the embodiments of the present invention will be described in detail with the accompanying drawings. However, it should be noted that the drawings are simplified schematic diagrams, and the basic structure or implementation methods of the present invention are illustrated only by schematic methods, so they are only shown related to the present invention. The elements and combination relationships of are not used to limit the present invention.

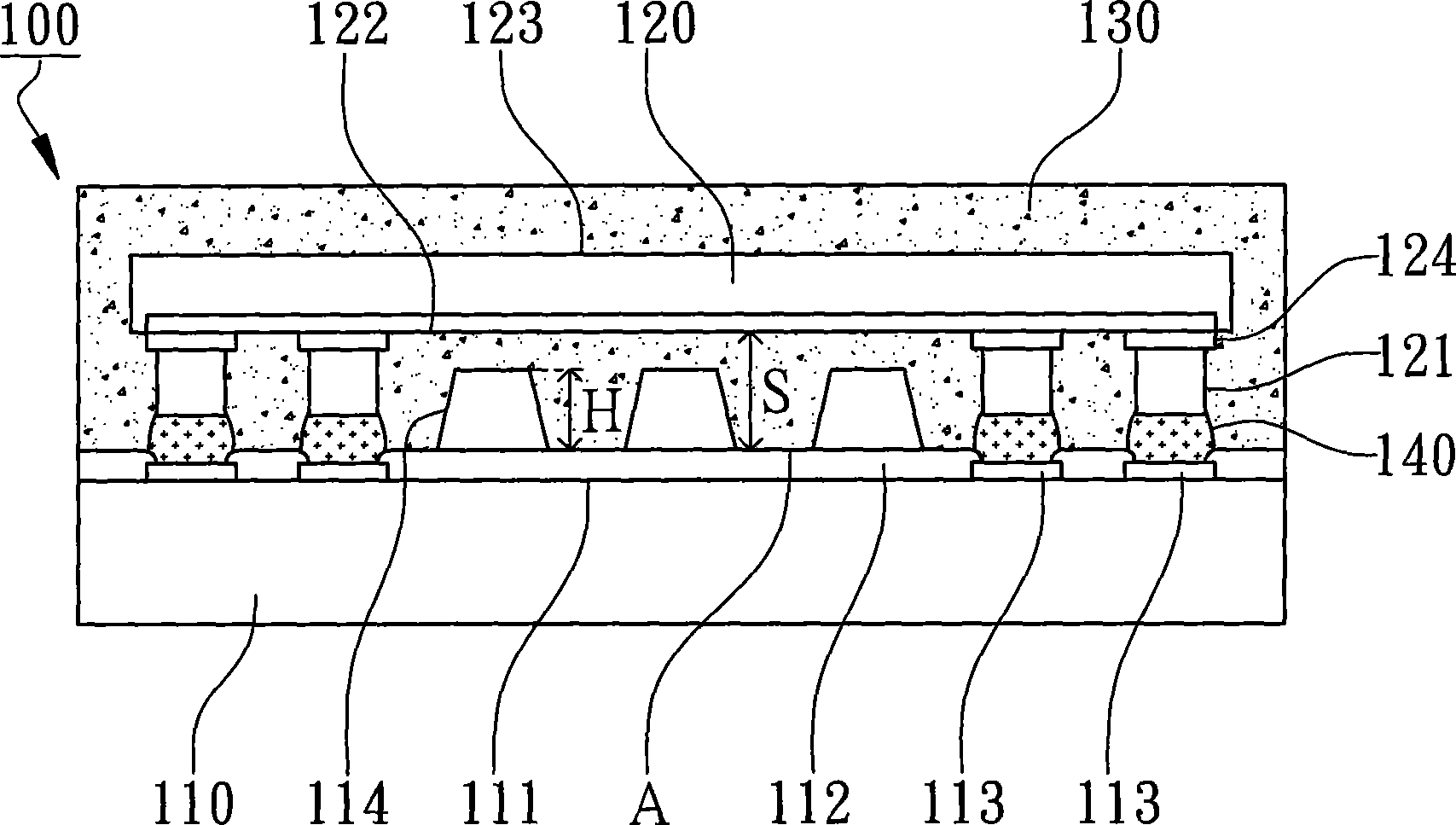

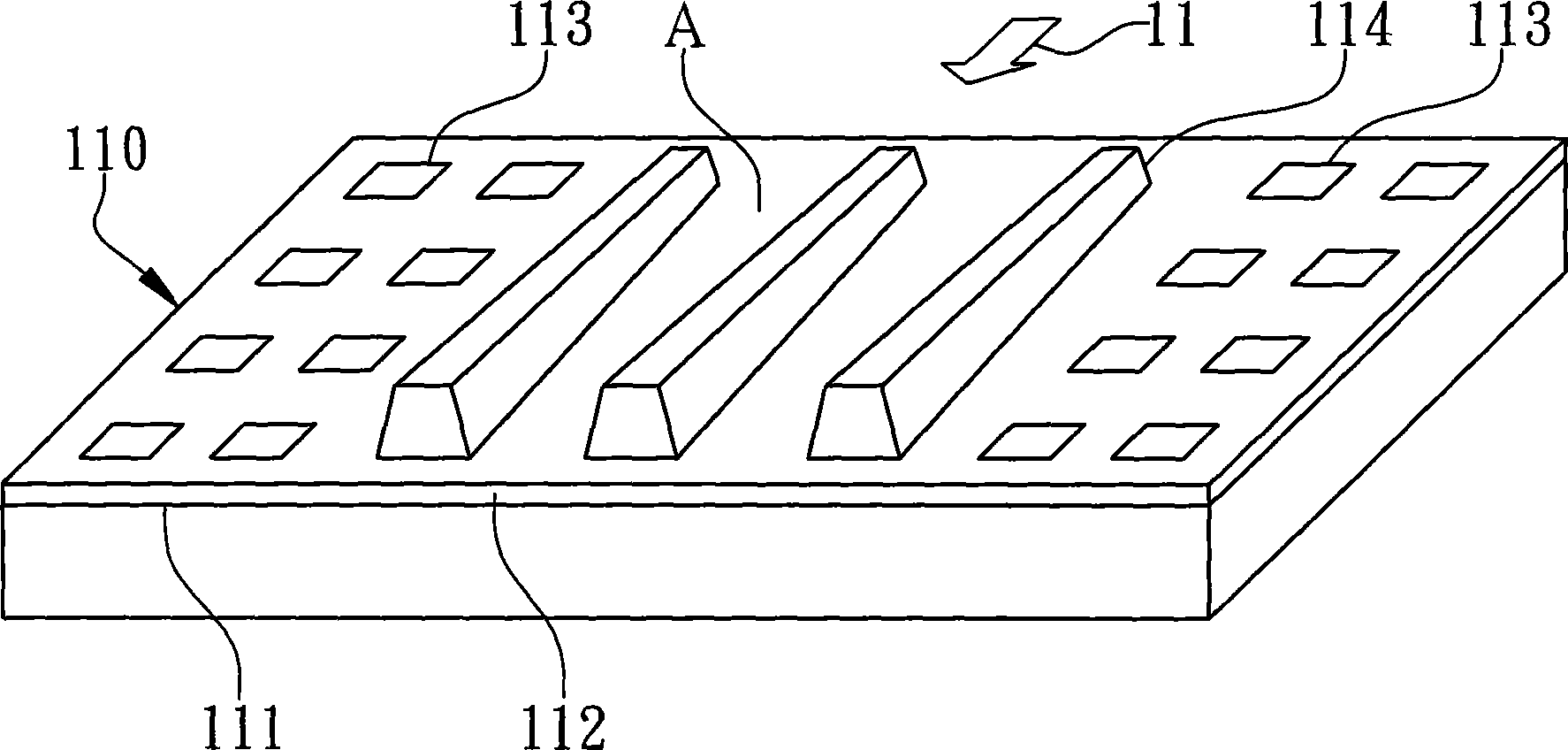

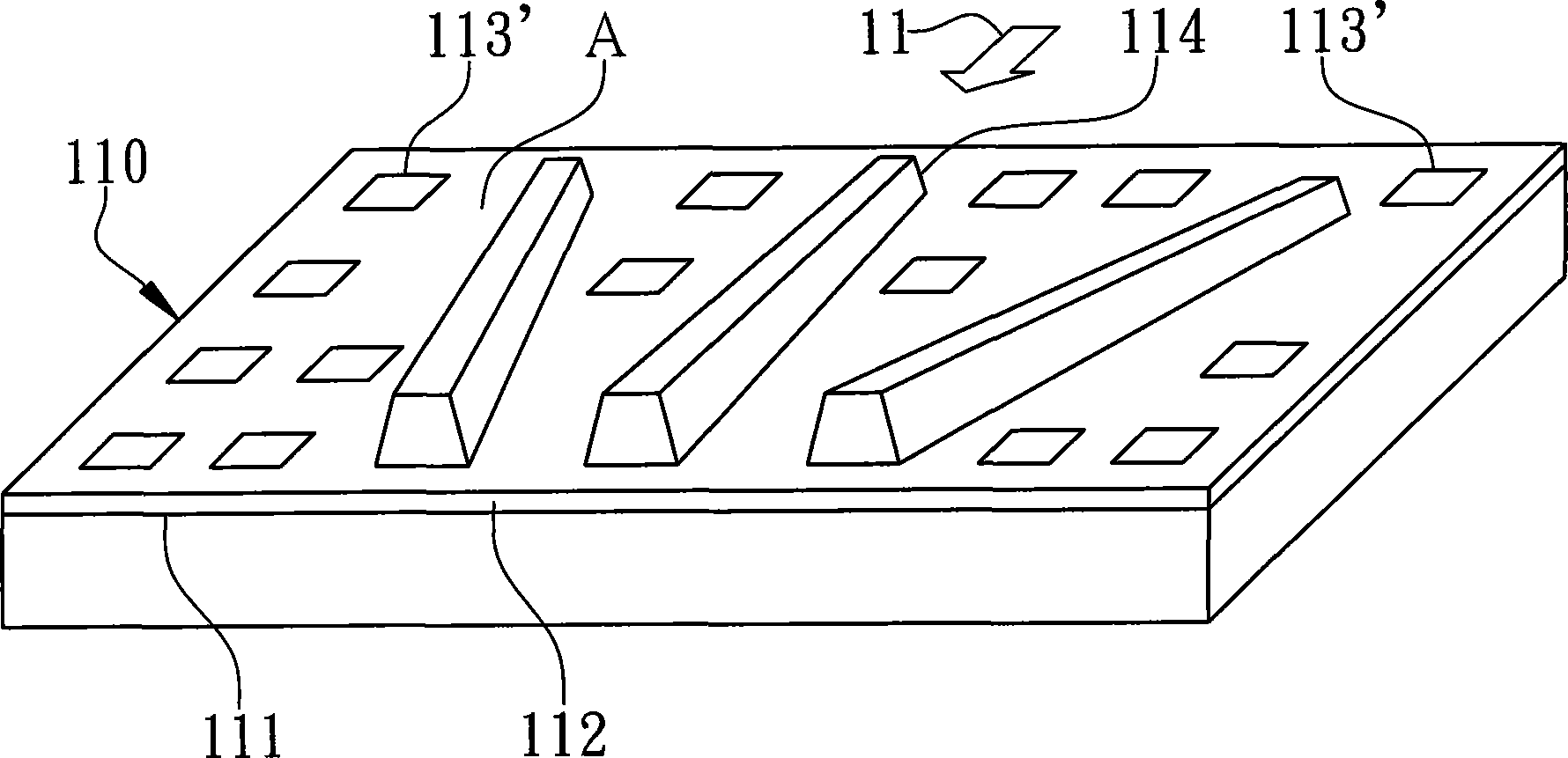

[0038] According to a specific embodiment of the present invention, a flip chip encapsulation structure of non-array bumps is illustrated in figure 1 The cross-sectional schematic diagram and figure 2 3D schematic diagram of the substrate. The flip chip encapsulation structure 100 of non-array bumps mainly includes a substrate 110, a chip 120 and a molding compound 130.

[0039] The substrate 110 has an upper surface 111 covered with a solder mask 112, and the upper surface 111 is provided with a plurality of pads 113 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com