Telescopic support for the construction industry

A telescopic and pillar technology, which is applied to the preparation of pillars, buildings, and building components on site, can solve the problems of high cost and complex manufacturing technology of telescopic pillars, and achieve reliable maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

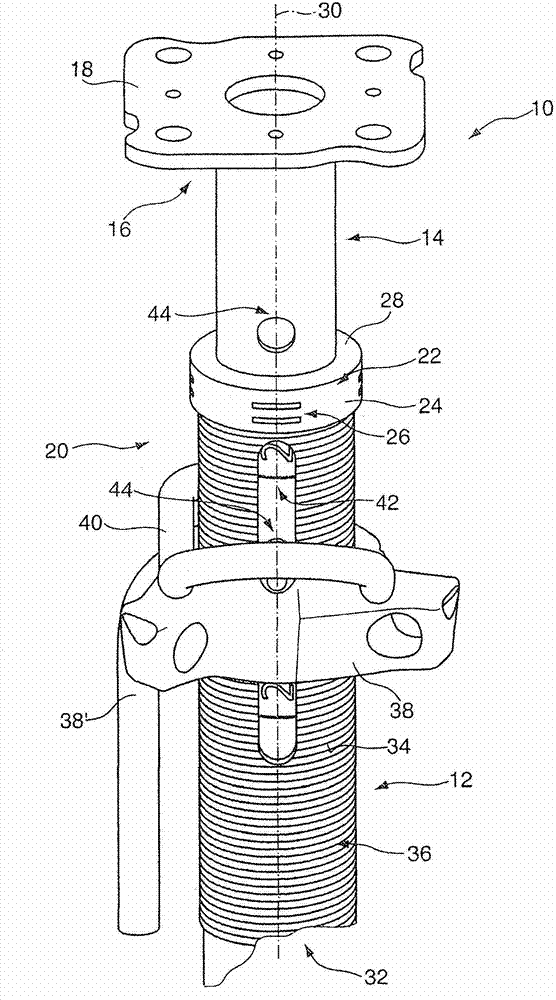

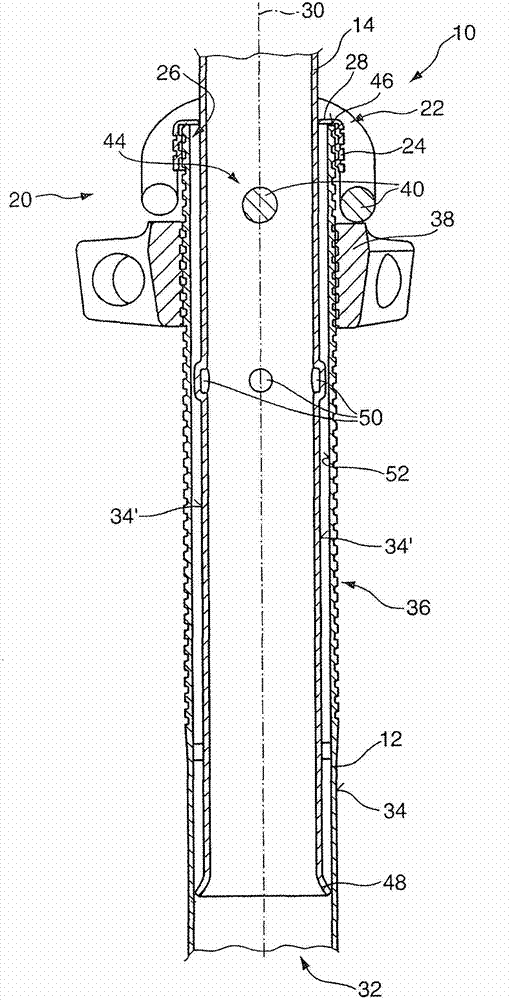

[0025] figure 1 A selected column section of a telescoping column for the construction field, generally indicated at 10, is shown in . The telescoping strut 10 has an outer tube 12 and an inner tube 14 arranged axially displaceable in the outer tube. The inner tube 14 has a known bearing plate 18 on its free end 16 shown in the upper part of the figure, and the outer tube 12 has a bearing plate 18 on its base-side end, which is not shown in detail in the figure, for secure positioning. base plate on the corresponding bottom foundation.

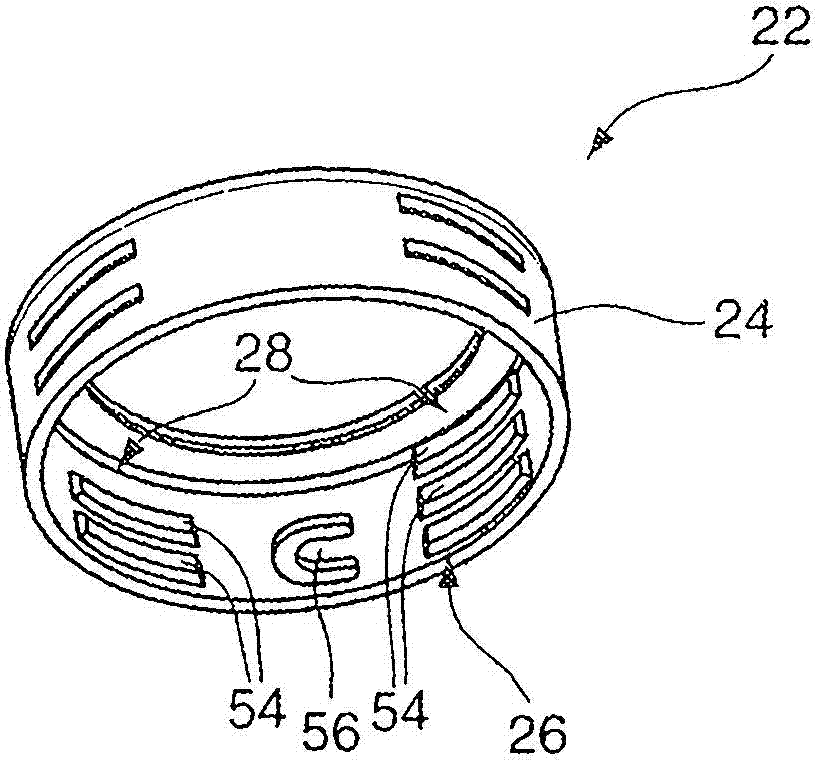

[0026] A cover 22 is arranged on the top side of the outer tube 12 , that is, towards the end 20 of the support plate 18 of the inner tube 14 , which serves as a stop element for the inner tube 14 and prevents the inner tube 14 from the outer tube by means of the cover. 12 axially move out or fall out.

[0027] The cap 22 is configured in a manner corresponding to a cap nut and has an approximately cylindrical wall section 24 provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com