An apparatus for directionally arranging blank tubes of an automatic doffer

A technology of directional arrangement and automatic doffing, used in textiles and papermaking, etc., can solve the problems of high labor intensity, low efficiency, large adhesion, etc., and achieve the effect of reducing labor intensity and labor cost, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

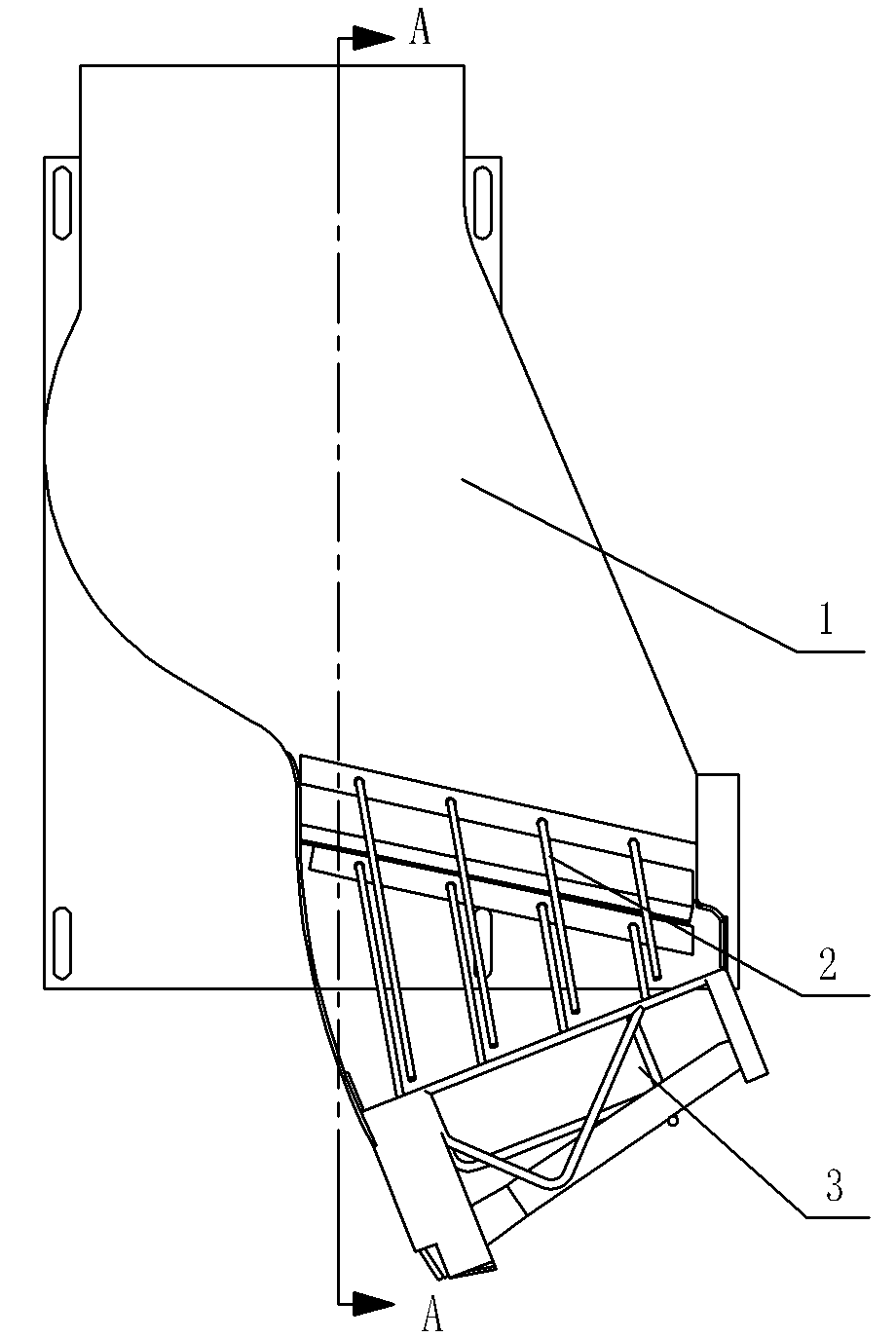

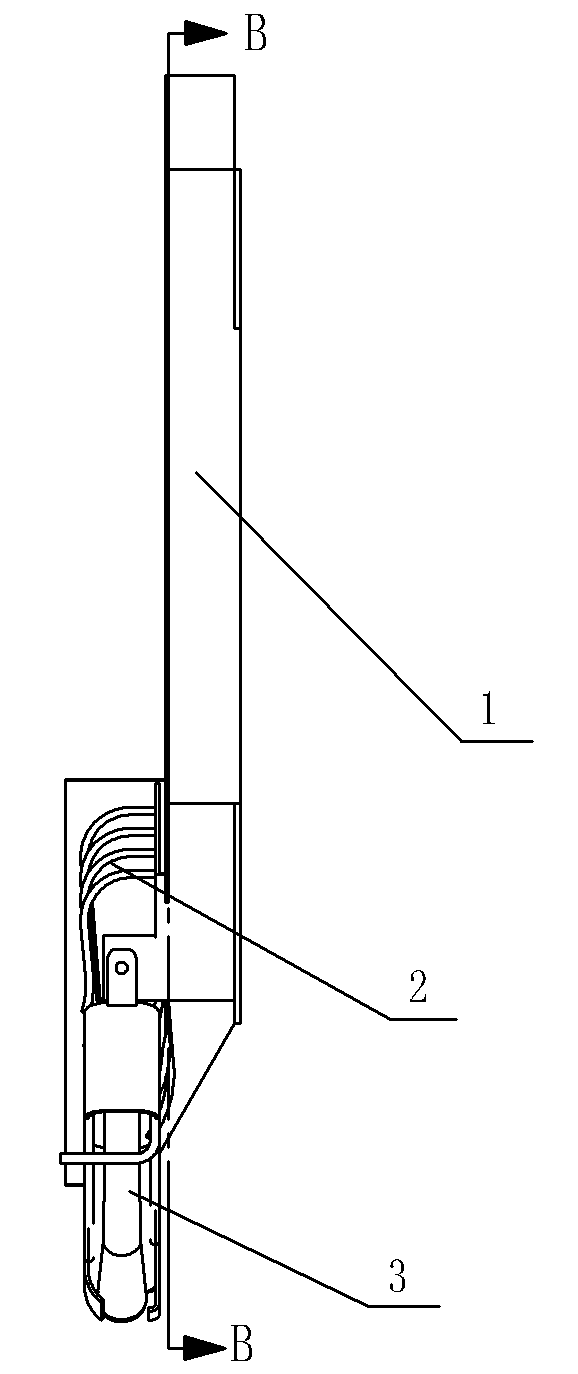

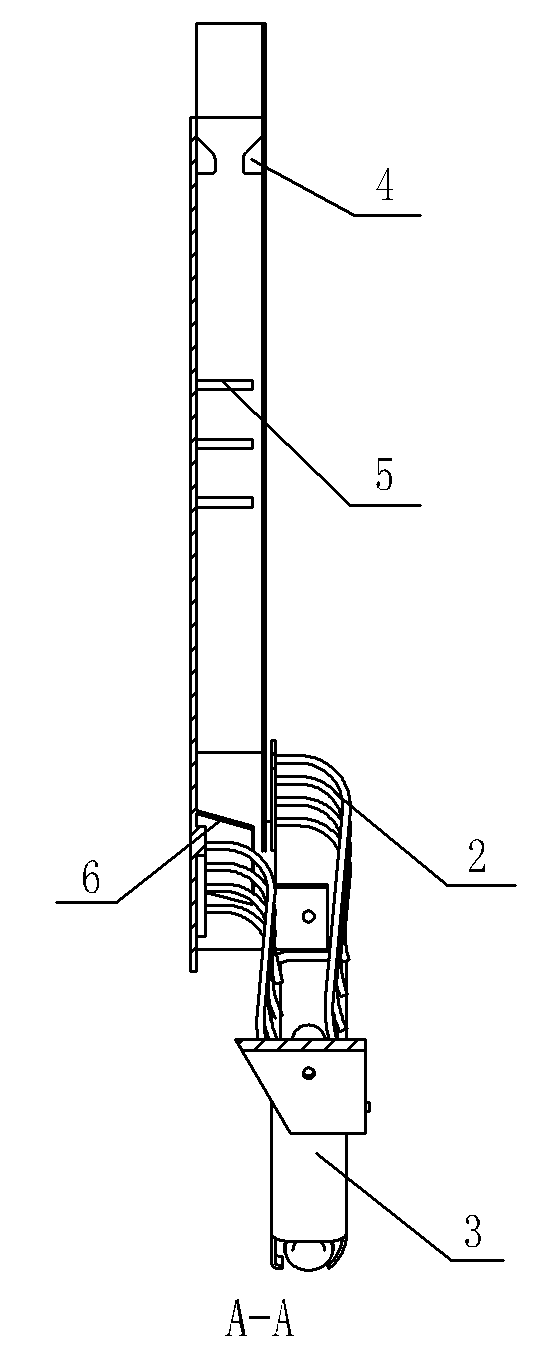

[0016] Such as Figure 1 ~ Figure 4 As shown, the present invention comprises a hollow box body 1, and the top and the bottom of box body 1 are provided with openings, and a pair of protrusions 4 are respectively arranged on the left and right sides of the top opening, and the protrusions 4 are welded on the front and rear side walls of the box body, Each pair of protrusions 4 is opposite to form a gap, the width of the gap is smaller than the diameter of the large end of the empty pipe and slightly larger than the diameter of the small end of the empty pipe, and the width of the middle section of the top opening is greater than the diameter of the large end of the empty pipe, so that the empty pipe can pass through it; The left side wall 8 protrudes to the outside of the box body to form a concave arc surface, and the right side wall 7 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com