Double-blade impeller

A double-blade, vane technology, applied in the field of double-blade impellers, can solve the problems of working environment impact, gas not being discharged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

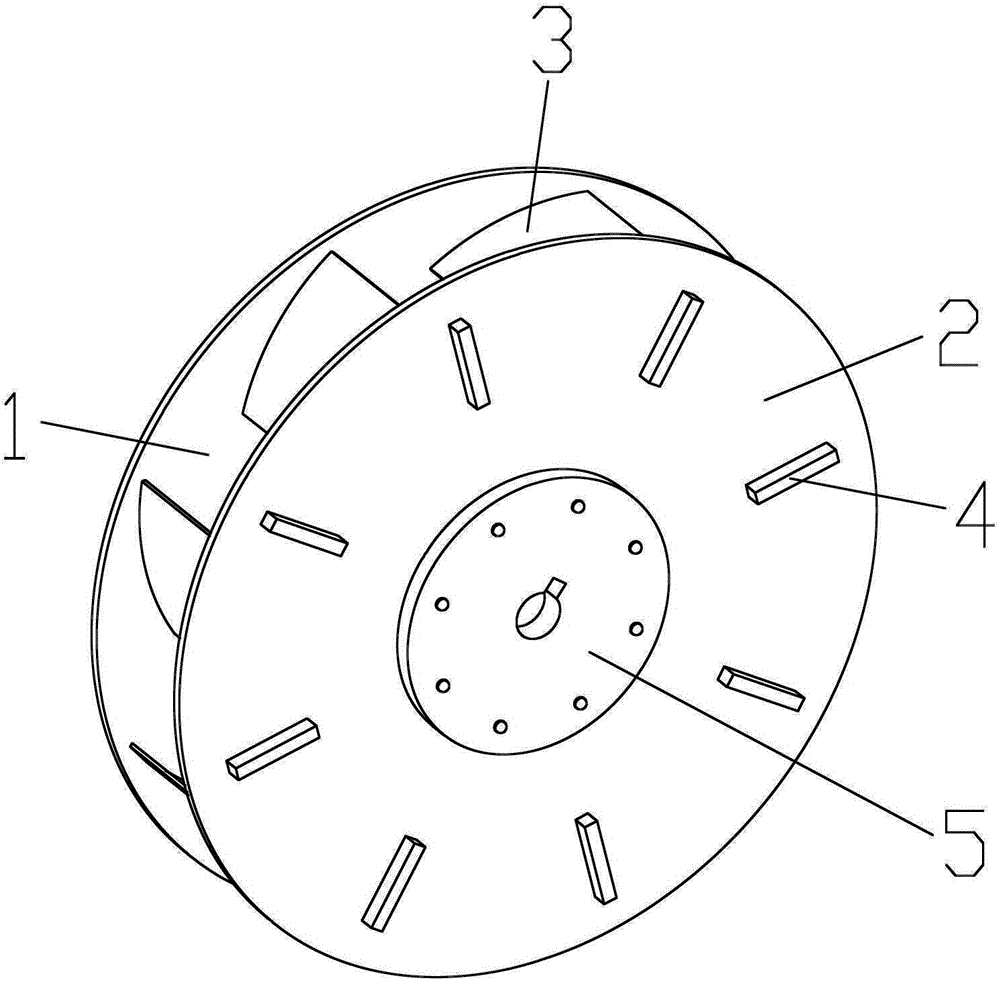

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 The shown double-blade impeller of the present invention includes a front cover plate 1, a rear cover plate 2 and blades 3, and a plurality of first blades 3 are arranged in an annular array between the front cover plate 1 and the rear cover plate 2, The rear surface of the rear cover 2 has a plurality of second blades 4 in an annular array; the number of the first blades 3 is the same as the number of the second blades 4; the center of the rear surface of the rear cover 2 is provided with a boss 5; the boss 5 is located within the circumference formed by a plurality of second blades 4; the height of the boss 5 is greater than the height of the second blade 4

[0014] The double-blade impeller of the present invention enables the gas at the rear of the impeller to be discharged, avoiding the impact on the surrounding working environment caused by the gas wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com