Oil seal and pivoting support employing same

A technology for slewing bearings and oil seals, which is applied to shafts, bearings, bearing components, and engine seals. It can solve problems such as poor dustproof effect, single sealing structure, and affecting the service life of slewing bearings, and achieve enhanced rigidity and good dustproofing. The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

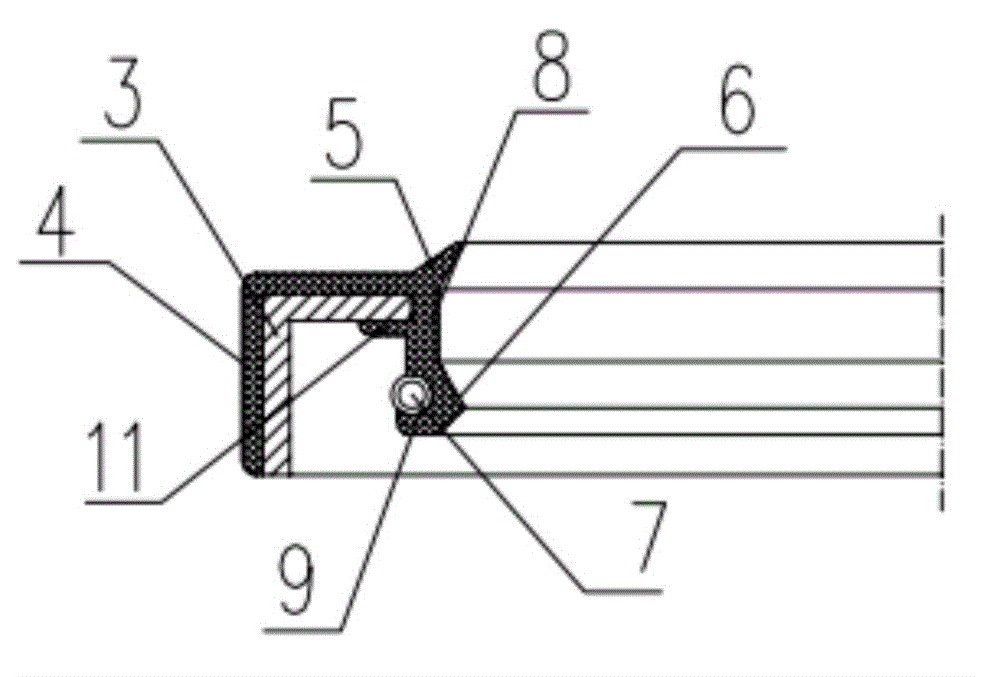

[0020] to combine figure 1 , an oil seal in this embodiment, including an oil lip and an L-shaped steel plate frame 3, a connecting base 4 of the oil lip is provided on the outside of the steel plate frame, the connecting base is connected to an oil lip section 8, and the two ends of the oil lip section are provided with direction The upper right and lower right protrusions, wherein the upper right protrusion is the outer oil lip 5, and the lower right protrusion is the inner oil lip 6. An annular groove 9 is provided on the side of the oil lip segment away from the inner oil lip, and a spring ring 7 is arranged in the annular groove. The oil lip section is provided with a long protrusion 11, and the long protrusion is close to the steel plate framework 3 and fastens the steel plate framework 3 inside.

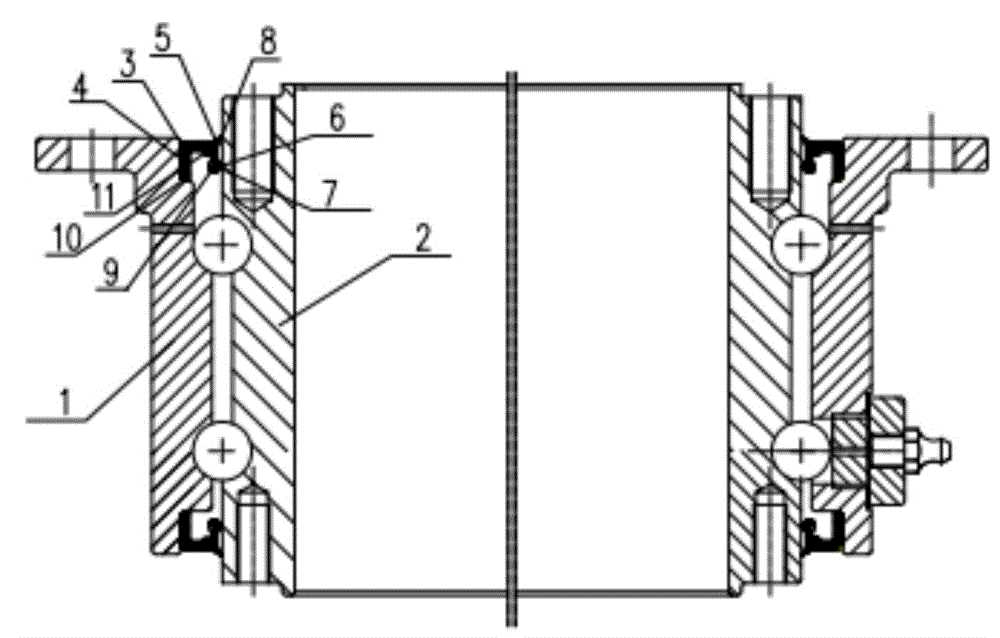

[0021] to combine figure 2 , a slewing bearing using the above-mentioned oil seal, an annular shallow groove 10 is provided on the inner diameter of the outer ring 1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com