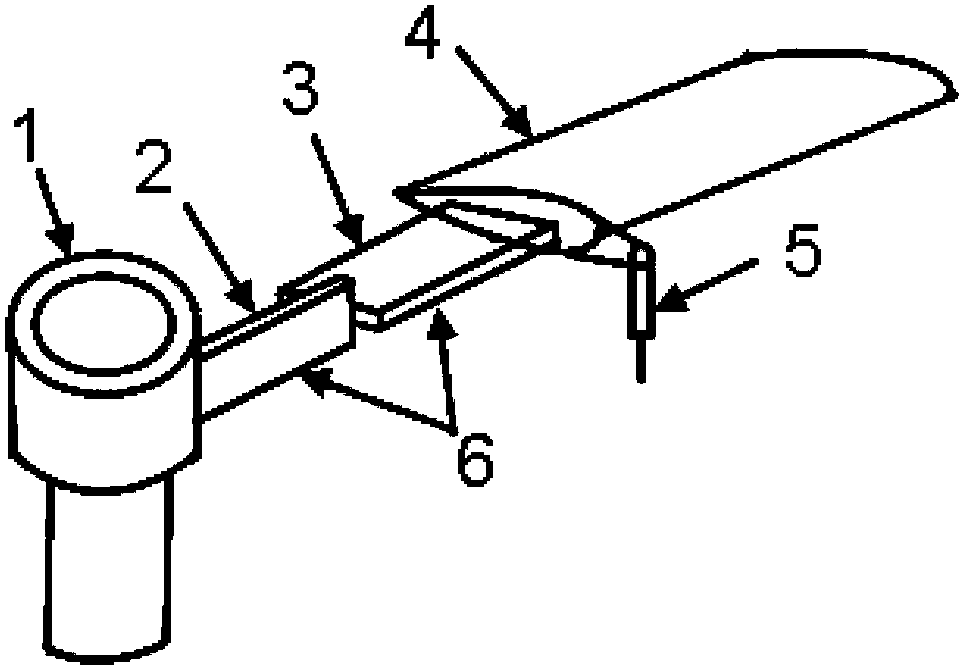

Hingeless rotor blade model and layer pavement design method thereof

A technology of rotor blades and design methods, applied in computing, special data processing applications, instruments, etc., to achieve the effect of improving aeroelastic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

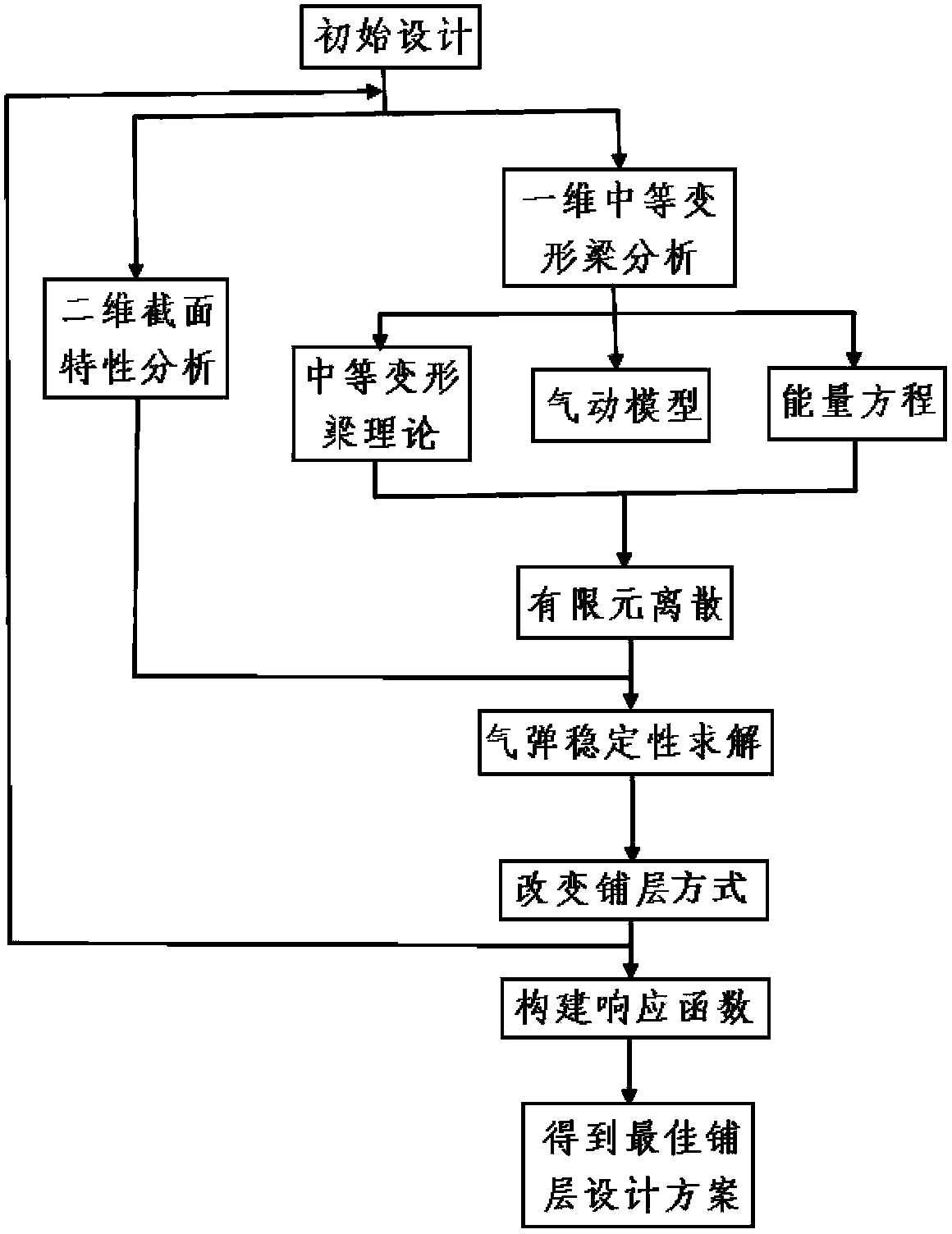

Method used

Image

Examples

Embodiment

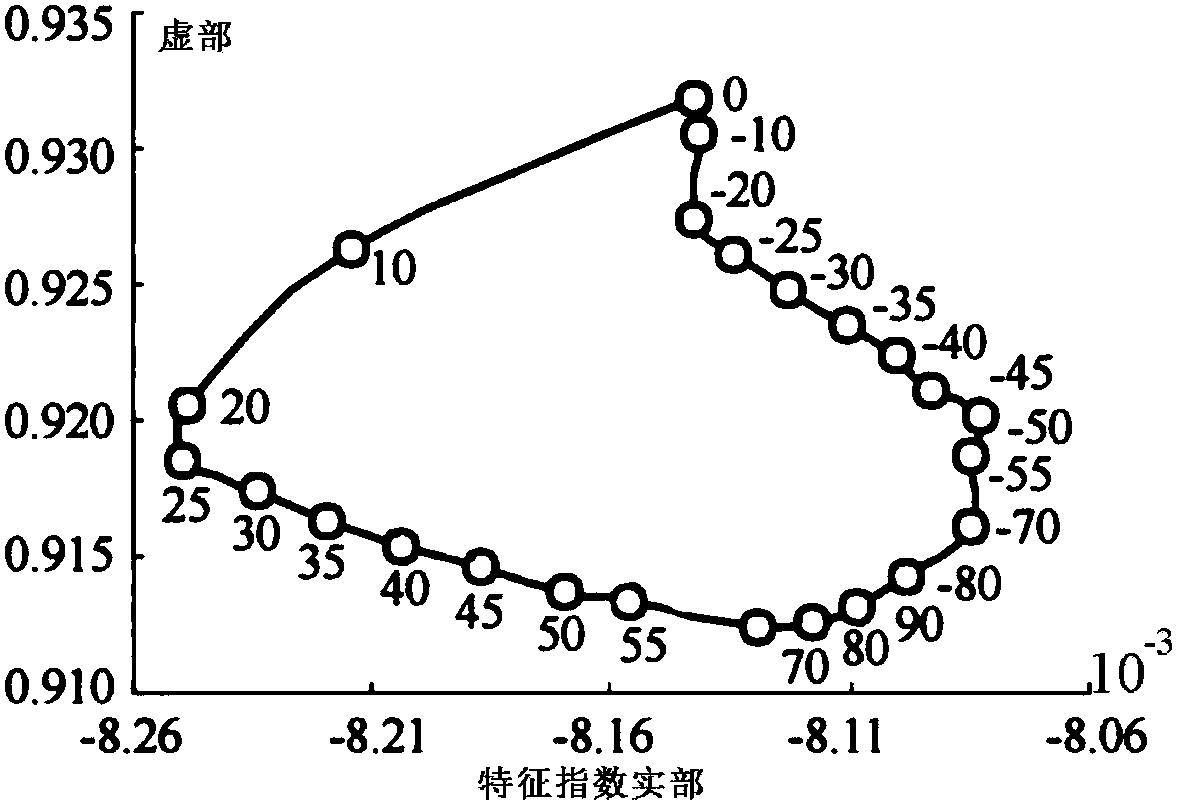

[0036] The proposed method is used to study the composite rotor blade layup method, and the structure and aerodynamic parameters of a certain type of helicopter rotor system are selected, specifically the number of blades is 4, the radius of the blade is 5m, and the chord length of the blade is 0.08m. Speed 40s -1 . In order to simplify the calculation, an angle between the horizontal flexible beam and the vertical flexible beam is selected as the design parameter here. The angle A in the initial design is 90°, and the influence of the number of composite material layers is not considered.

[0037] Table 1 Lamination design scheme of flexible beams

[0038]

[0039] The layup design scheme is expressed as 3 layers of composite material with layup angle A, then 3 layers of 15° and -15° double-layer structure, and finally 2 layers of 0° layup. The value range of A is between 0° and 90°. By calculation, it can be obtained as image 3 The functional relationship sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com