Core for racket string, racket string comprising such a core and corresponding manufacturing method

A core wire and string technology, which is used in the manufacture of stringed rackets, rackets, rayon, etc., can solve the problems that the method is difficult to industrialize and the core wire does not have strings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

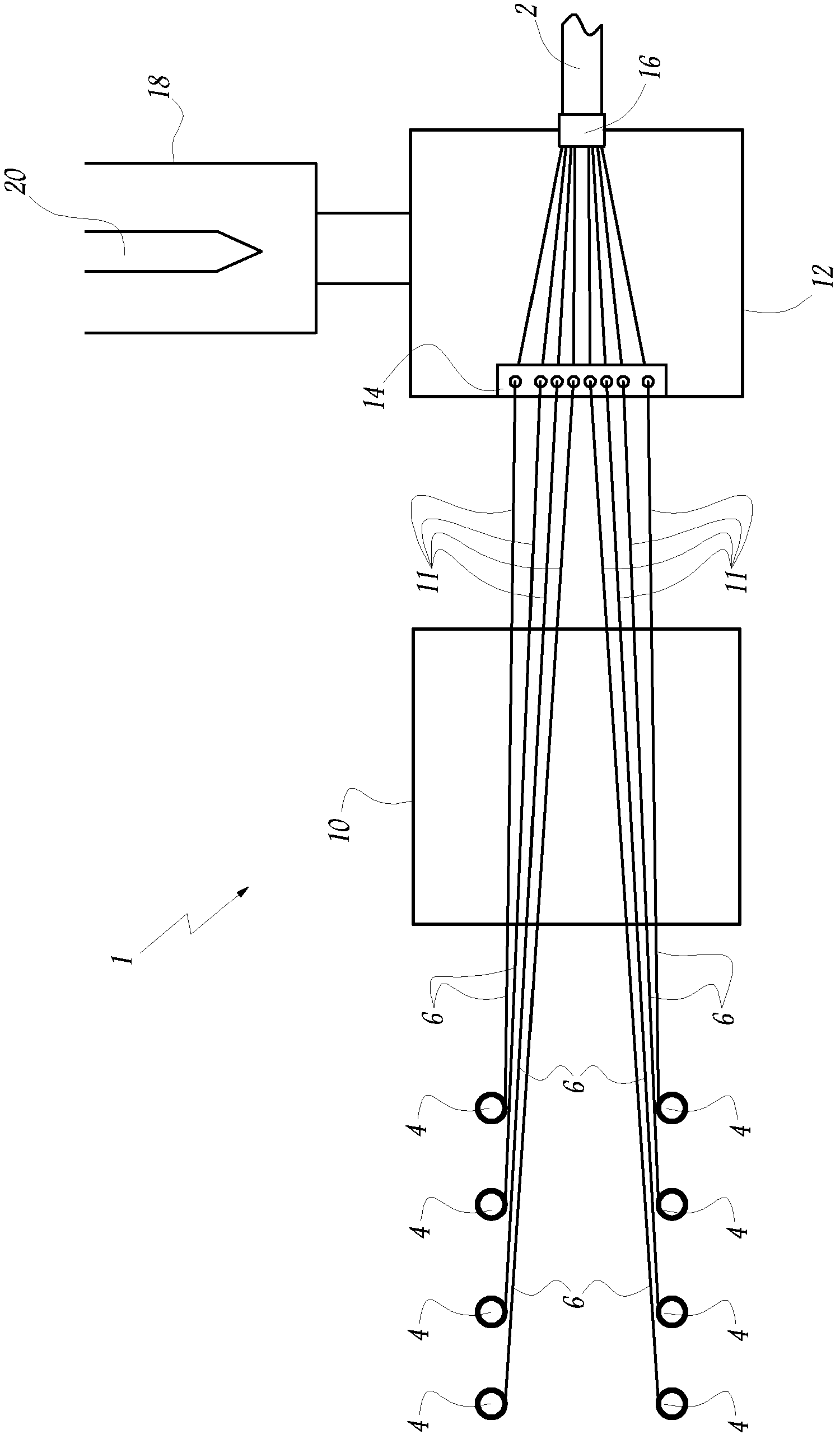

[0029] figure 1 The assembly 1 of the core wire 2 used to make the string of the racket is shown. The assembly 1 includes eight bobbins 4. A plurality of fibers 6, which may be called "multi-fibers", or unit threads are wound around each of the spools. In the following sections, for the sake of simplicity, it will be referred to as line 6.

[0030] It is possible to design and use a different number of coils from the example shown. Therefore, the diameter of the core wire 2 can be changed. All the fibers of thread 6 are of natural origin. It can also be specified that one or more of the fibers are of natural origin. Advantageously, the fiber can be made of silk, and the silk can be produced from silkworms, spiders, or transgenic animals capable of producing silk. In this regard, it will be noted that spider genes have been transplanted on goats and silkworms.

[0031] In the sense of the present invention, fibers of natural origin refer to processed or unprocessed silks deriv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com