Under-beam transmission device for electron beam irradiation vulcanization of tire component

A technology for irradiating and vulcanizing tires with electron beams, applied to tires, other household appliances, household appliances, etc., can solve problems such as the inability to meet the rubber tire components, the lack of tire film, the lack of versatility, etc., and achieve high production efficiency and operation. Convenience and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

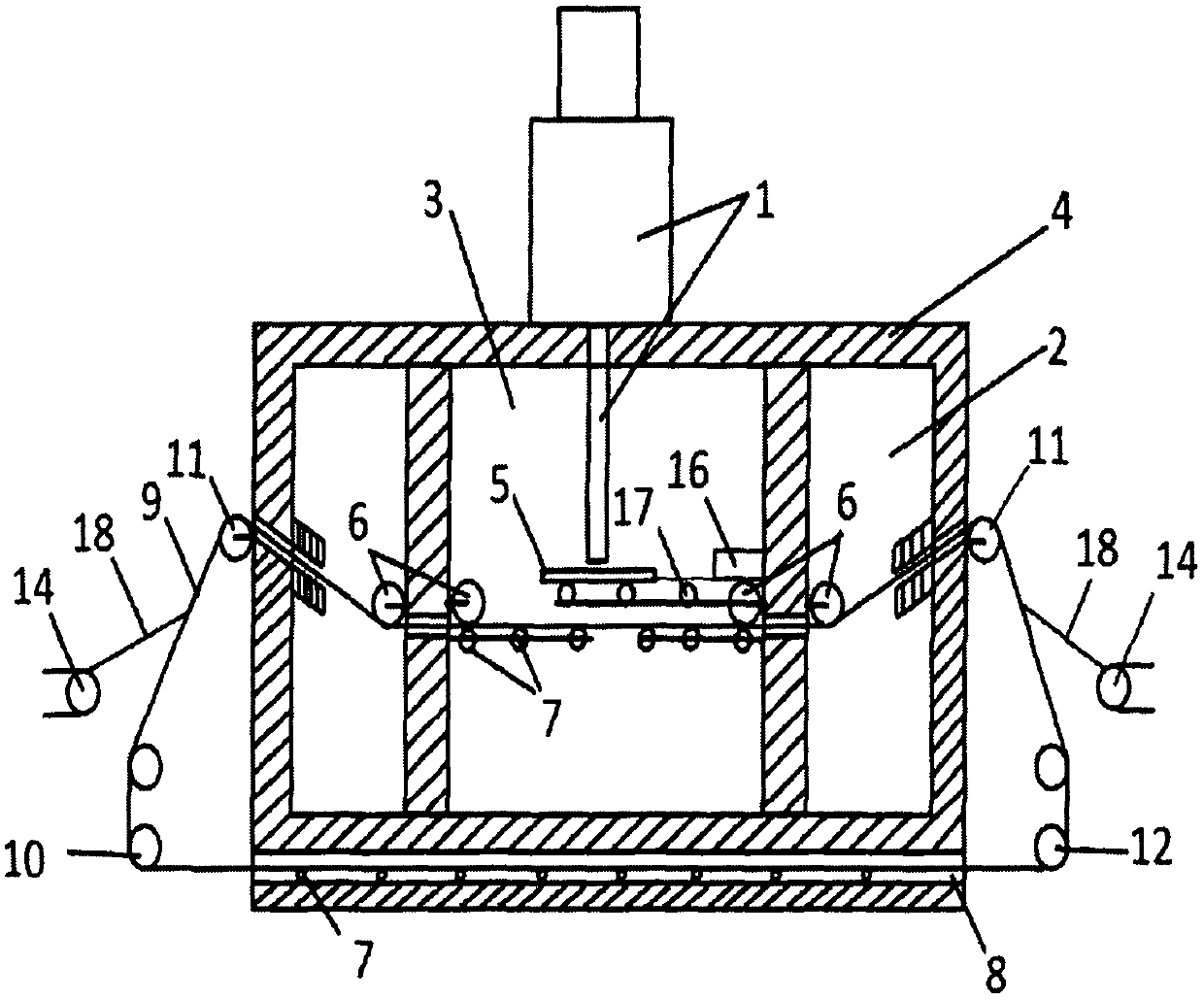

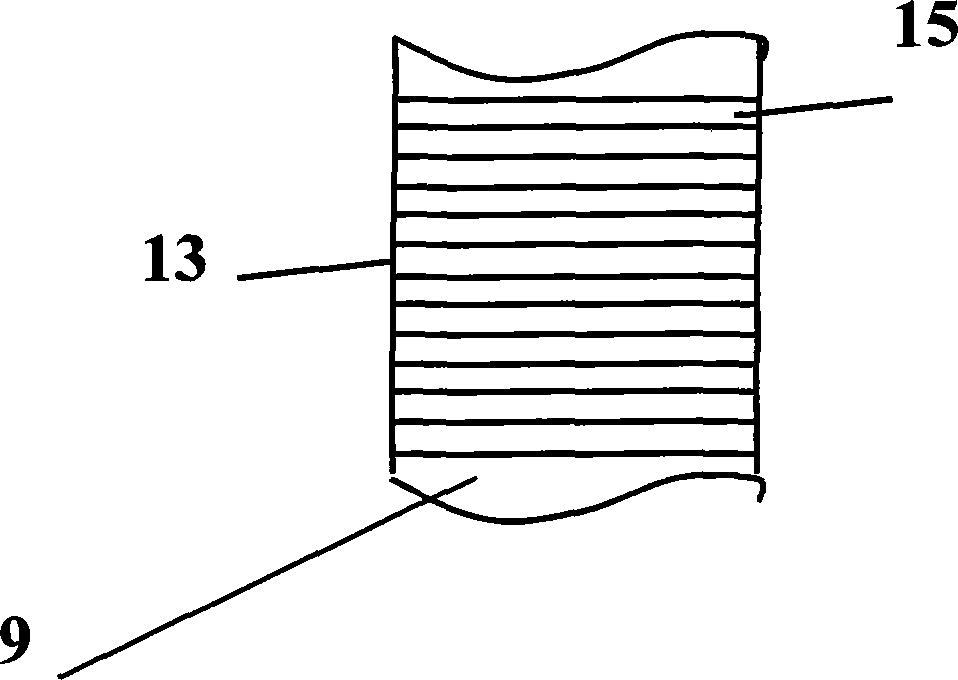

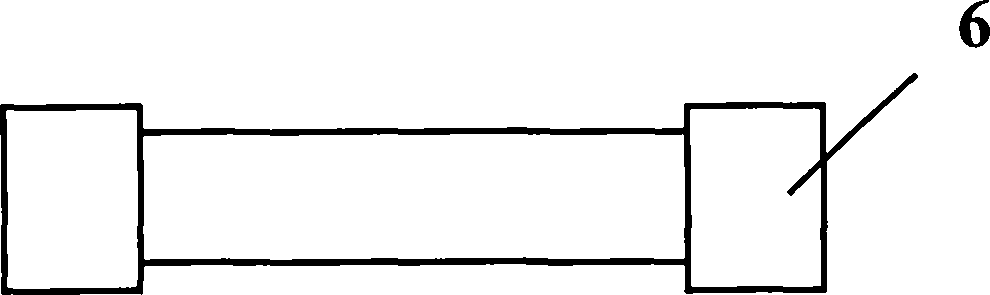

[0014] Attached below figure 1 - attached image 3Describe the present invention in detail, a kind of electron beam irradiation vulcanization tire component beam transmission device, by electron accelerator 1, transition room 2, irradiation room 3, steel shielding body 4, beam current baffle 5, beam current baffle cylinder 16. Beam baffle guide rail 17, stainless steel I-shaped wheel 6, stainless steel pulley 7, cooling air duct 8, closed stainless steel slat conveyor belt 9, tensioner 10, stainless steel guide wheel 11, driving device 12 and front and rear retractors Conveyor belt 14 is put and curled; the space inside the steel shielding body 4 is divided into an irradiation chamber 3 and a transition chamber 2 on the left and right sides. The bottom of the steel shielding body 4 is designed with a horizontal cooling air duct, and an electron accelerator is installed on the upper part of the irradiation chamber 3. 1. The titanium window on the electron accelerator 1 passes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com