Artificial diamond blister tray molding equipment

A technology of molding equipment and blister trays, which is applied in the field of blister molding equipment for rhinestone blister trays, can solve the problems of low molding efficiency, inconvenient operation, and unstable movements, etc., and achieves simple and reasonable structure, convenient operation, The effect of improving the efficiency of blister molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

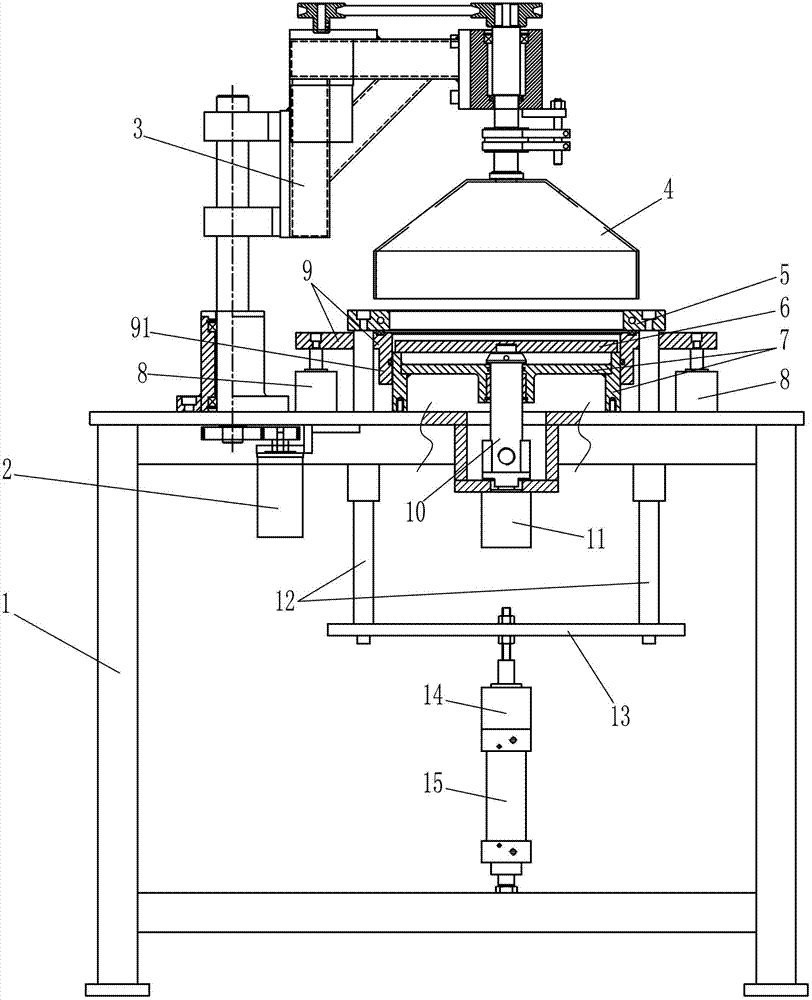

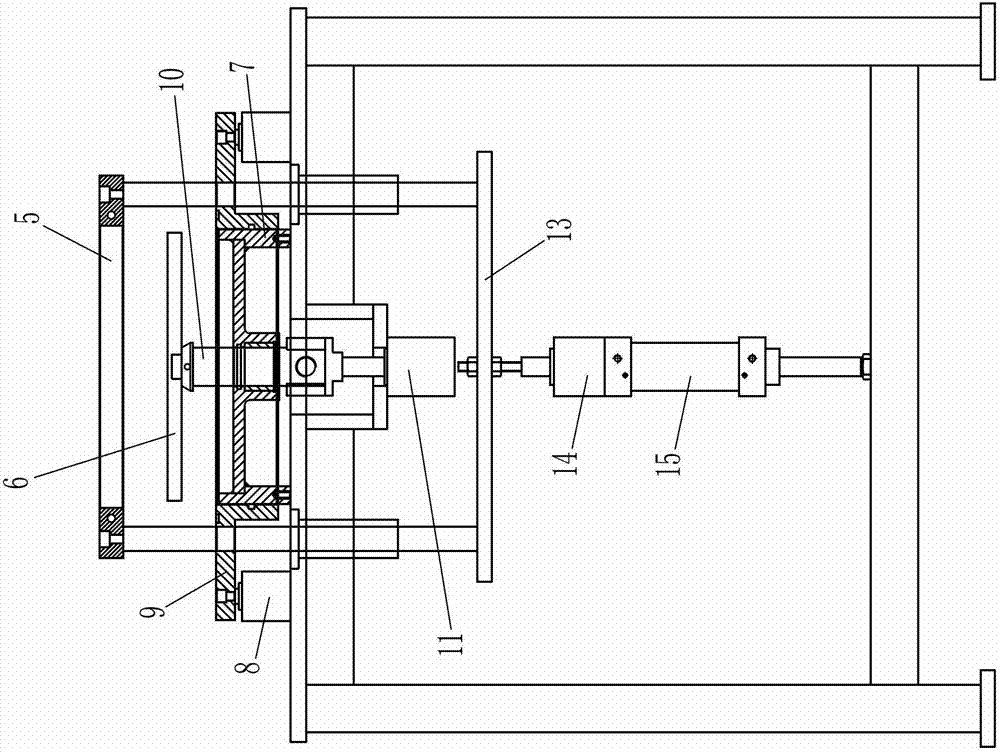

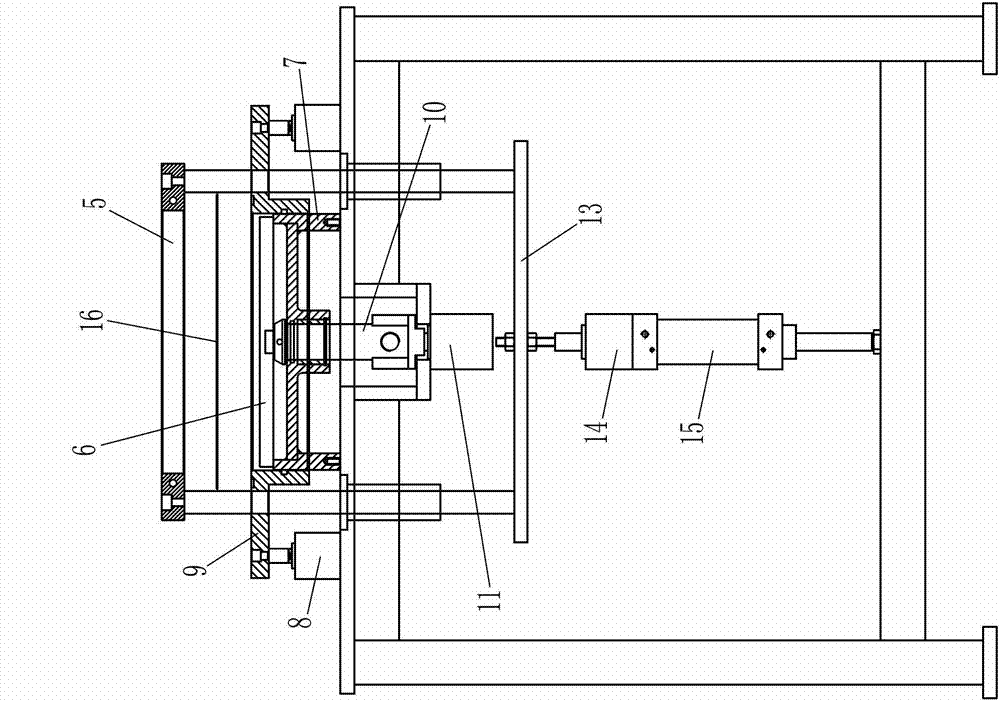

[0020] Such as figure 1 The molding equipment for a rhinestone blister tray shown includes a frame 1, a vacuum pump (not shown in the figure) and a heater 4, the frame 1 is fixed with a base 7, and a suction template is arranged on the base 7 9. The suction template 9 is provided with a pressure frame plate 5 that clamps the plastic-absorbing material 16 together with the suction template 9. The tooling plate 6 is placed in the center of the suction template 9. The tooling plate 6 is provided with several embedding holes for embedding rhinestones. The bottom of the hole is provided with a ventilation hole, which communicates with the vacuum pump through the ventilation pipe 10, and the heater 4 can be erected above the pressure frame plate 5 through a moving mechanism; the side circumference of the tooling plate 6 and the suction template 9 or the annular ring There is a gap between 91, which communicates with the vacuum pump through the vent pipe 10; the frame pressing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com