Piston compressor

A compressor and piston technology, applied in the field of piston compressors, can solve problems such as cylinder sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

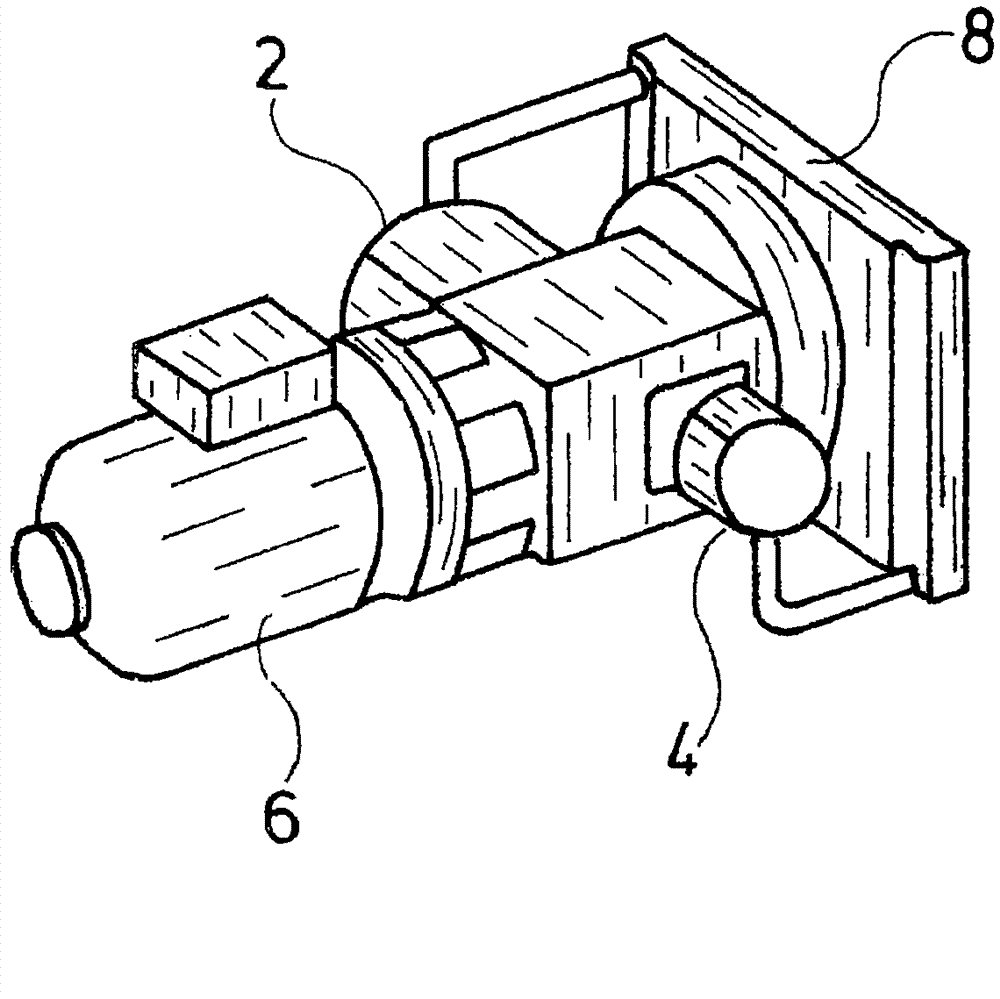

[0028] figure 1 The basic structure of a reciprocating compressor is shown, the reciprocating compressor shown here being of a two-stage type with two cylinders 2 and 4 . Pistons arranged in cylinders are driven by electric motor 6 via a common shaft. However, other drives can also be used, for example internal combustion engines. The cylinder 2 constitutes the first stage of the piston compressor, the gas compressed in the cylinder 2 being conveyed to the second stage via an intercooler 4 . exist figure 1 As can be seen in the figure, cylinder 4 of the second stage is smaller than cylinder 2, that is to say has a smaller working volume inside it, since the gas entering cylinder 4 has already been compressed in the first stage, cylinder 2. Correspondingly, the diameter of the second-stage piston 10 is also smaller than that of the first-stage piston.

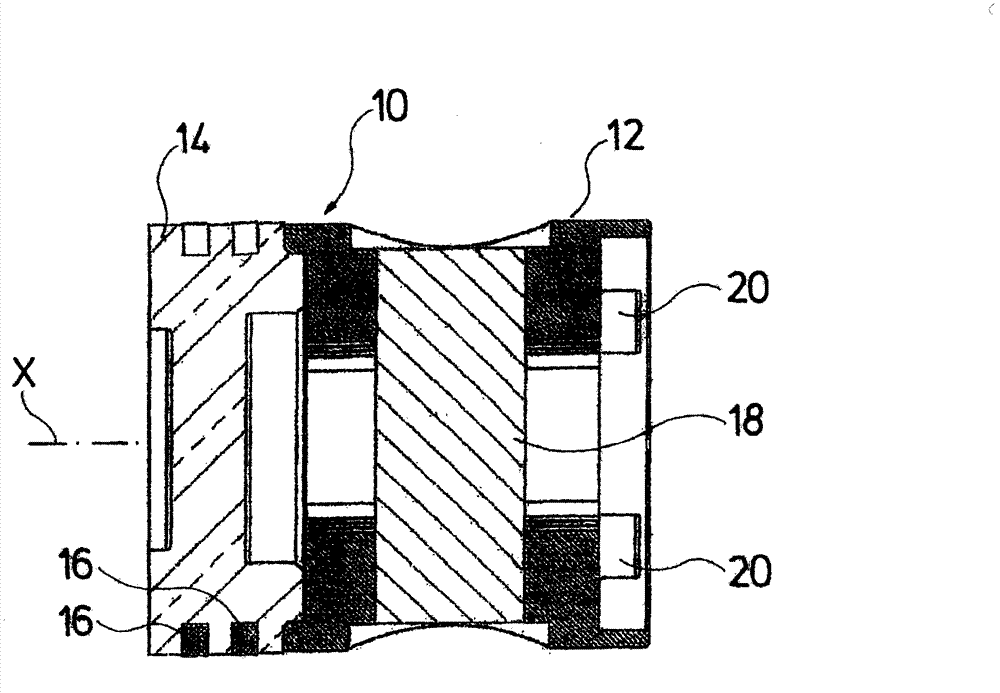

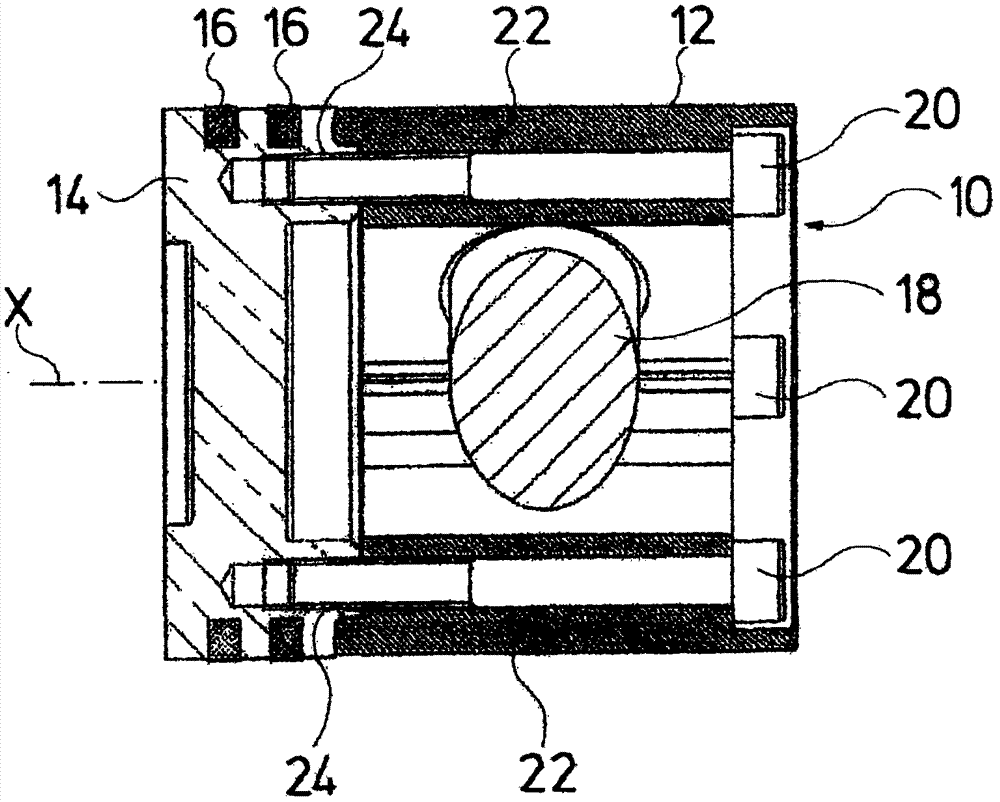

[0029] figure 2 and image 3 The structure of the piston 10 used in the second cylinder 4 in the second stage is shown....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com