power conversion device

A power conversion device and power consumption technology, which is applied in the direction of converting irreversible DC power input into AC power output, controlling electromechanical transmission devices, and deceleration devices of AC motors, etc., can solve the problem of increasing motor power consumption, increasing motor loss and consumption And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

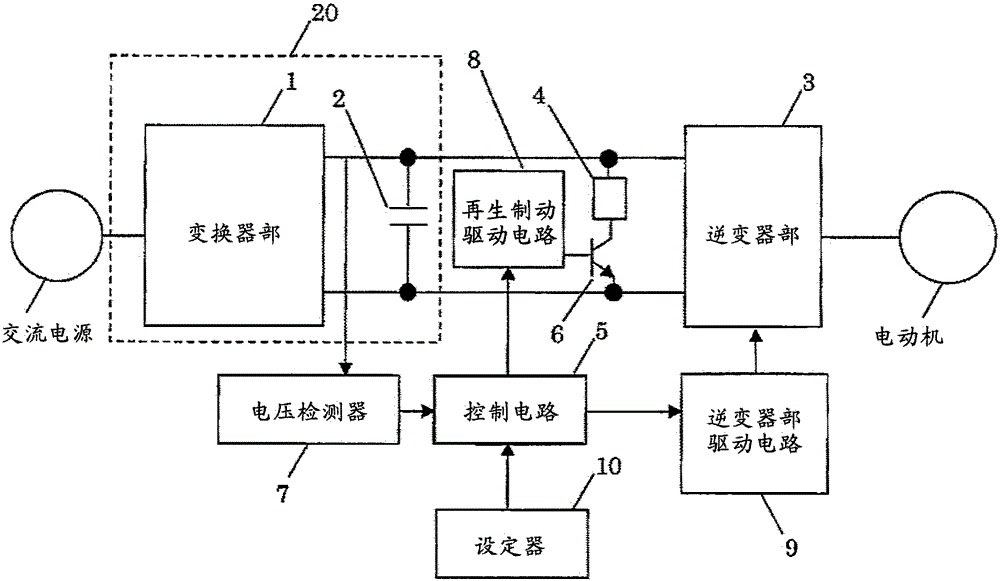

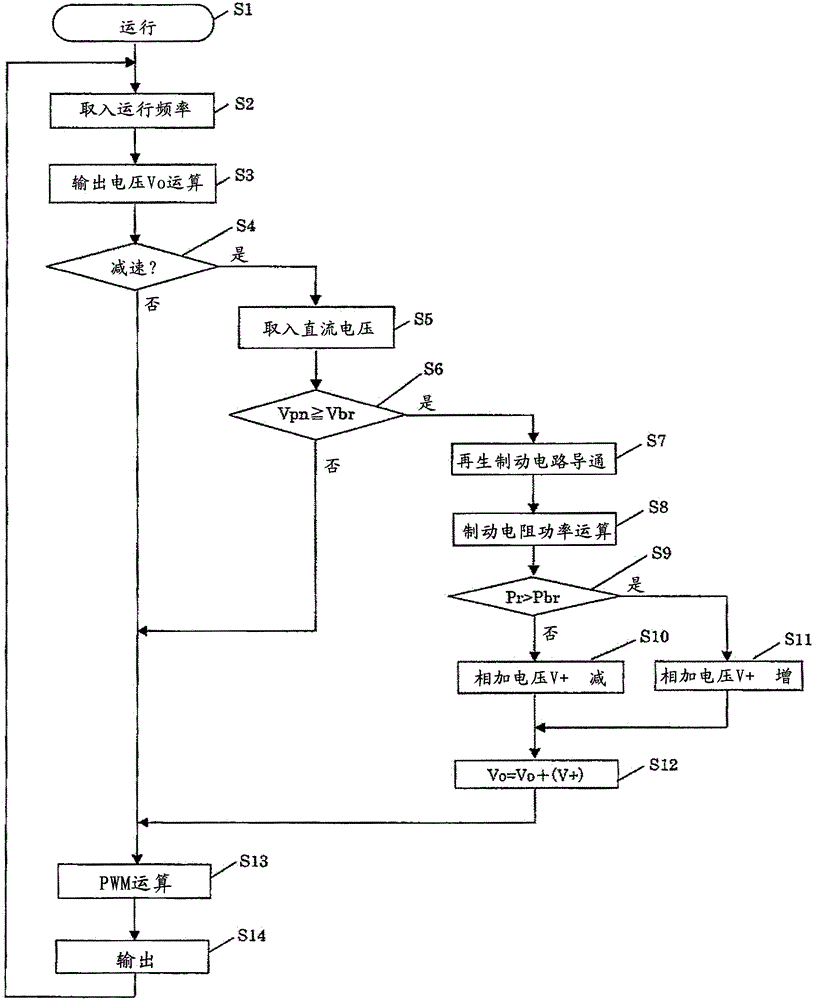

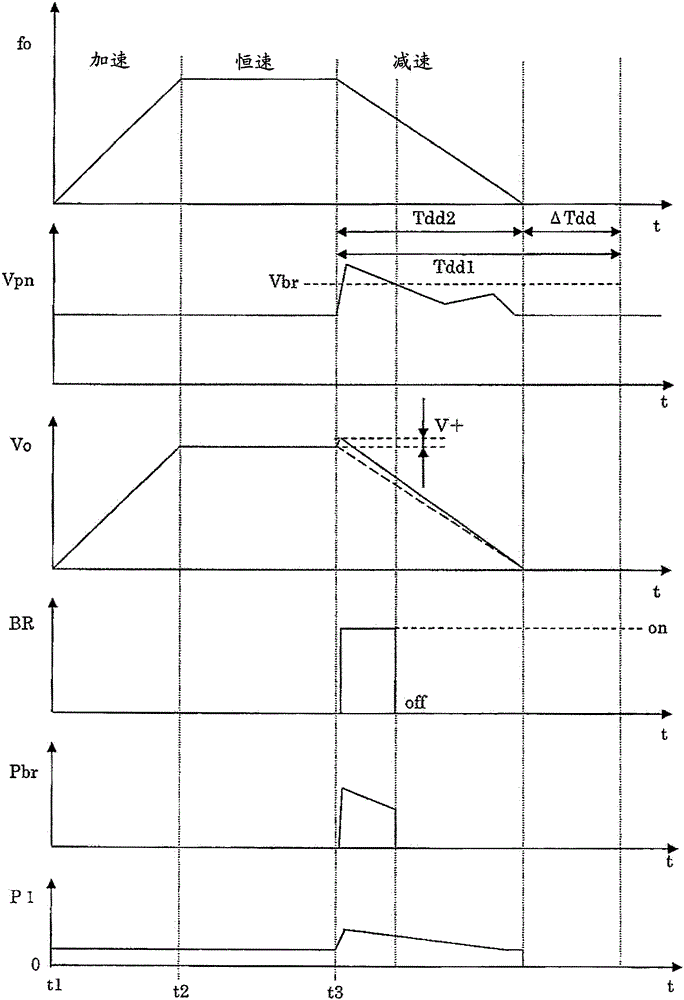

[0019] figure 1 is a structural diagram of this embodiment. The AC power is rectified by the inverter unit 1 and the capacitor 2 to convert it into a DC voltage. The inverter unit 3 converts the DC voltage into a required AC voltage and outputs it to the motor. The transistor 6 functions as a switch for operating the regenerative braking resistor 4 . According to the regenerative operation state during the deceleration operation of the motor, conduction operation is performed when the inverter regenerates energy, and the regenerated energy is consumed as heat by the regenerative braking resistor 4 .

[0020] The voltage detector 7 constantly monitors the voltage of the DC unit 20 and sends a DC voltage signal Vpn to the control circuit 5 . The setting device 10 is a device for performing various settings such as the output frequency of the inverter, and sends various set values to the control circuit 5 . The MCU (not shown) installed in the control circuit 5 performs var...

Embodiment 2

[0068] If the value for increasing the output voltage is too large, the heat generation of the motor will further increase, and the motor itself may burn out. Therefore, it is necessary to set limits on the added voltage V+ according to the characteristics of the motor.

[0069] In Embodiment 1, when the amount of regeneration is large and the output voltage Vo reaches the limit value, the regenerative power cannot be completely consumed in the regenerative braking resistor 4, the voltage Vpn of the DC part 20 rises, and finally the overvoltage protection is implemented, resulting in The inverter stops.

[0070] A temperature sensor is generally built into the regenerative braking resistor 4. When the excessive regeneration amount is consumed as heat, the temperature of the resistor element rises sharply, and the temperature sensor operates to protect the regenerative braking resistor 4. The transistor 6 is stopped for the purpose of preventing abnormal heat release. Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com