Parallel detection system and method

A detection system and detection method technology, applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve problems such as non-reusability, high price, and inability to digitize measurement results, and achieve the effect of solving non-reusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further details will be given below in conjunction with the embodiments shown in the accompanying drawings.

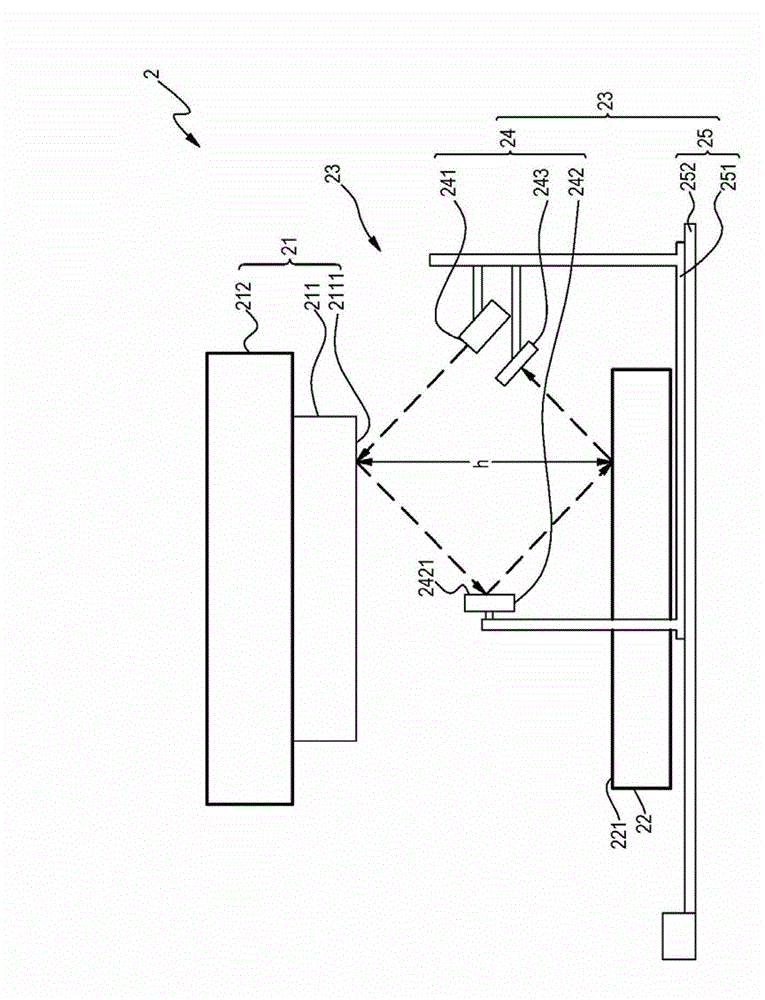

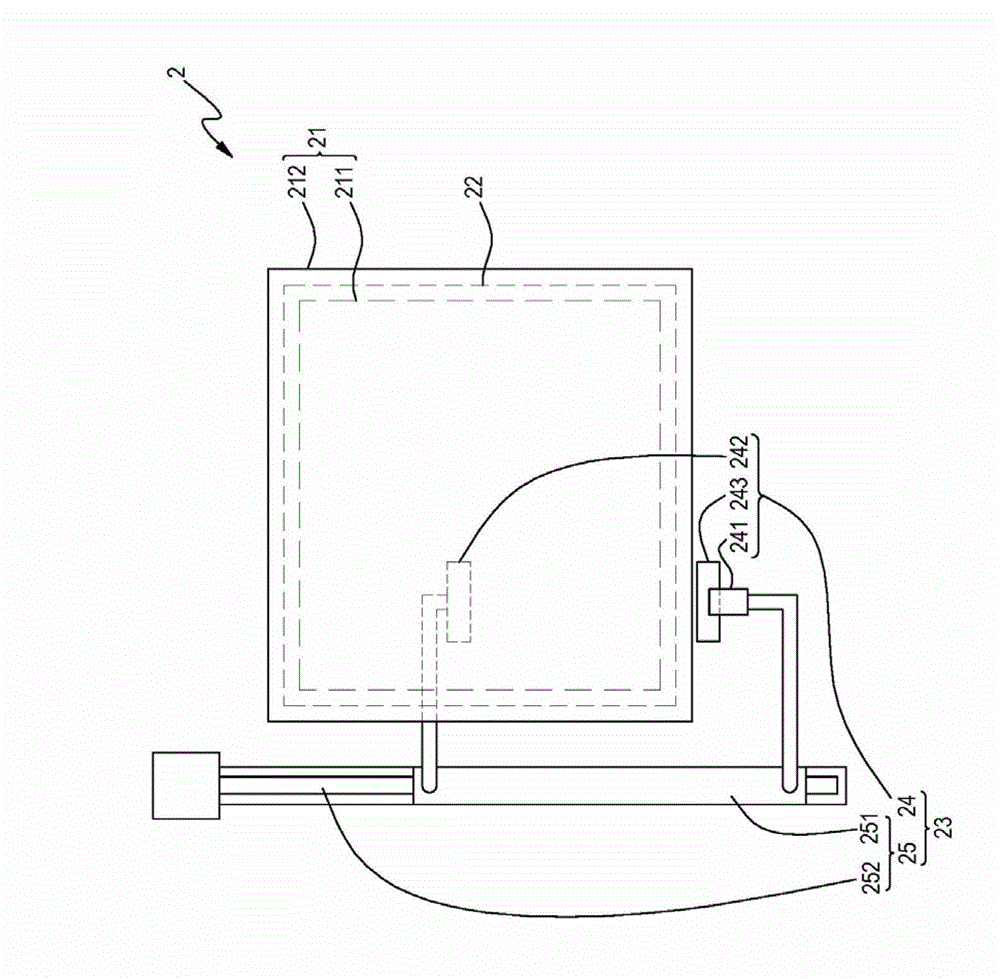

[0030] figure 2It is a structural diagram of the parallelism detection system 2 of the present invention. The parallelism detection system 2 includes a module to be tested 21 , a reference unit 22 and an optical measurement unit 23 . Wherein, the module under test 21 includes a unit under test 211 and an auxiliary unit 212 . The lower surface of the unit to be tested 211 is a flat surface to be tested 2111 , and the upper surface of the unit to be tested 211 is combined with the auxiliary unit 212 . The auxiliary unit 212 is used to adjust the inclination angle of the unit under test 211 and enable the unit under test 211 to move vertically up and down. The upper surface of the reference unit 22 is a flat reference surface 221 , so the reference surface 221 can be used as a reference plane for parallelism detection to compare the parallelism between the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com