Circuit and method for detecting remaining power of motor drive controller of electric vehicle

A motor drive and controller technology, applied in the direction of measuring current/voltage, measuring resistance/reactance/impedance, instruments, etc., can solve the problems of endangering personal and vehicle safety, inability to accurately detect residual electricity of capacitors, poor stability, etc., to achieve Improve the warning effect, broaden the detection range, and have high practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example 1

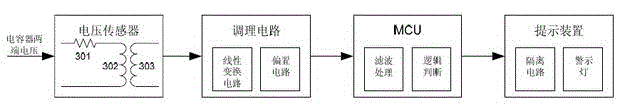

[0035] Such as figure 1 As shown, the voltage across the capacitor connected in parallel to the main circuit U IN The range of change is 0~600VDC, applied to the input resistance R IN =300kΩ, the current I generated in the primary circuit of the voltage sensor IN 0~2mA, the voltage sensor primary and secondary coil transformation ratio is 2.5, namely k 1 =2.5, the output current I in the secondary coil O The variation range is 0~5mA, the output current I in the secondary coil O Flow through the conditioning resistor R in the secondary loop 1 =500Ω, the generated voltage U 1 Is 0~2.5V, the voltage U 1 After bias adjustment, it is converted into a suitable range 0.3V~2.8V that can be collected by MCU, which is the bias voltage U of the bias circuit 3 =0.3V.

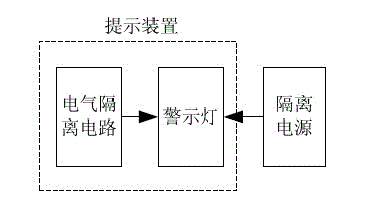

[0036] Such as figure 2 As shown, the signal transmission between the MCU and the prompting device adopts an isolation method, and the power supply of the prompting device also adopts a power supply isolated ...

Example Embodiment

[0044] Example 2

[0045] Such as figure 1 As shown, the voltage U across the capacitor connected in parallel on the main circuit IN The range of change is 0~1000V, applied to the input resistance R IN =100kΩ, the current I generated in the primary circuit of the voltage sensor IN 0~10mA, the voltage sensor primary and secondary coil transformation ratio is 2, namely k 1 =2, the output current I in the secondary coil O The variation range is 0-20mA, the output current I in the secondary coil O Flow through the conditioning resistor R in the secondary loop 1 =100Ω, the generated voltage U 1 0~2V, the bias circuit generates 0.2V, that is, the output voltage range of the bias circuit is 0.2~2.2V, the output voltage of the bias circuit is amplified by the linear conversion circuit twice and the output voltage is suitable for the MCU to collect The range is 0.4V~4.4V.

[0046] Such as figure 2 As shown, the signal transmission between the MCU and the prompting device adopts an isolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com