LED (light emitting diode) pixel tube light distribution process and novel LED pixel tube

A pixel tube and process technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems affecting the clarity and viewing angle of the display screen, the high dispersion rate of product testing, and the reduction of finished product shipments, etc., to achieve the benefit of mass production Production, optimization of display effects, and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

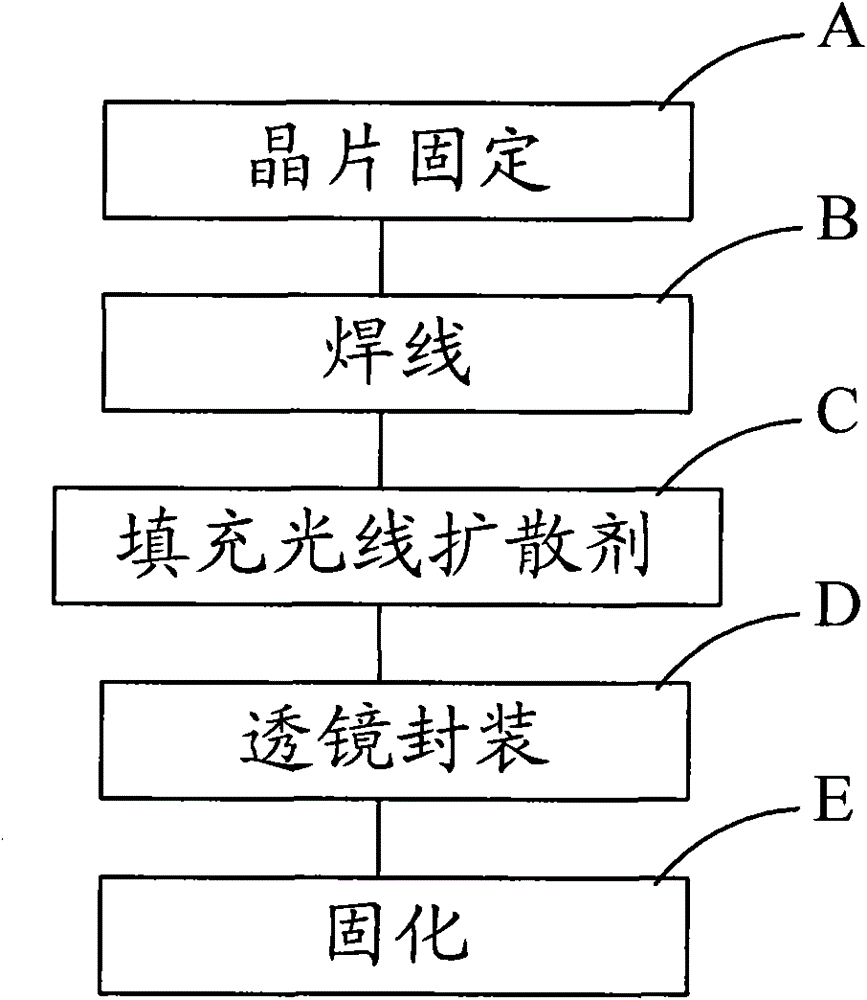

[0036] Such as figure 1 As shown, the LED pixel tube light distribution process of the present invention includes the steps:

[0037] A. Chip fixing: Fix the LED chip in the lead bracket lamp cup;

[0038] B. Wire bonding: Weld the chip solder joints with the bracket bonding wire area of the lead bracket lamp cup;

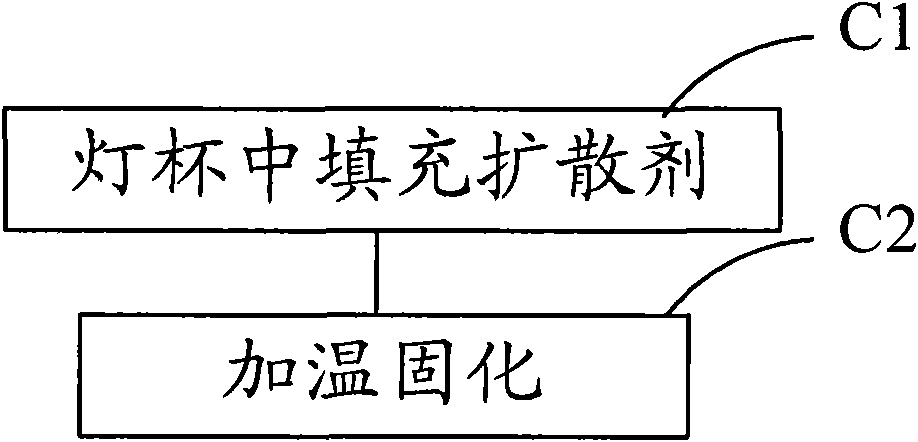

[0039] C. Filling with light diffusing agent: Fill the light diffusing agent in the lead bracket lamp cup of the welded wire;

[0040] D. Lens packaging: the lens is packaged in the mold cavity;

[0041] E. Curing: curing the lens material after the lens is packaged in the mold cavity.

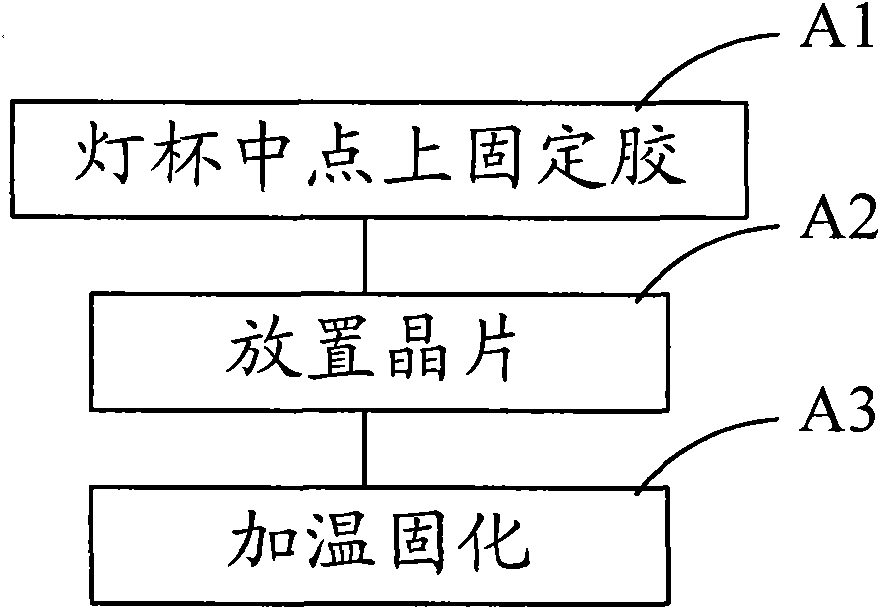

[0042] Specific as figure 2 As shown, the step A further includes:

[0043] A1. Point the LED chip fixing glue in the middle of the lead bracket lamp cup;

[0044] A2. The LED chip is placed in the lead bracket lamp cup;

[0045] A3. Put it into a hot air circulating oven and bake at 150~160℃ for 60 minutes for curing.

[0046] The soldering step uses an ultrasonic gold wire ball bonding machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com