Corner connector for connecting frame and frame

A frame and corner code technology, applied in the field of frame and its components, can solve the problems of not easy to achieve 45-degree angle cutting slope, difficult connection of corner code, poor force bearing capacity, etc., and achieve the effect of strong adaptability of connection and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

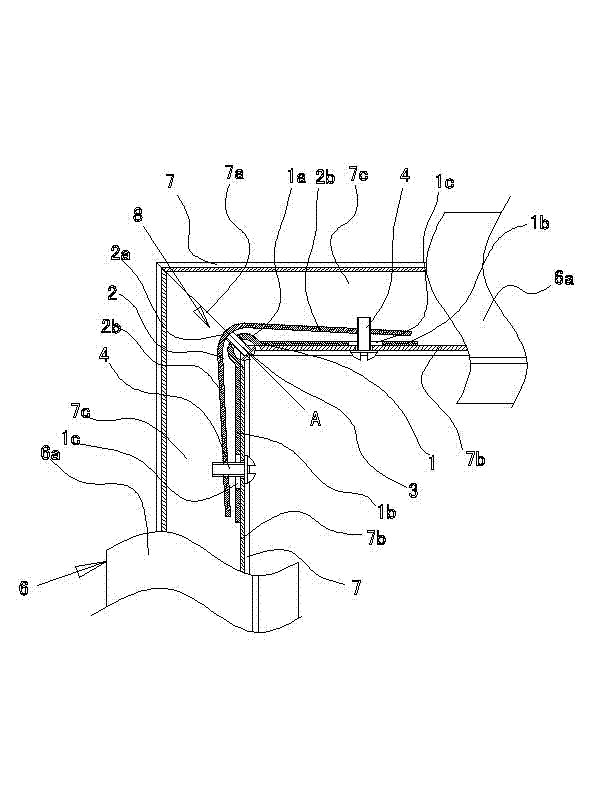

[0011] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0012] As shown in the figure, the corner code for frame connection of the present invention is realized in this way, including an inner angle bent plate 1, an outer angle bent plate 2, a push rod 3, and a screw 4, and the push rod 3 is along the angle 1a of the inner angle bent plate 1 The centerline A of the center line A is set on the angle 1a of the inner angle bending plate 1 and is supported on the angle 2a of the outer angle bending plate 2, and at least one screw 4 passes through the perforation 1c on the angle plate 1b of the inner angle bending plate 1 and is threaded on the outer angle on the corresponding corner plate 2b of the bent plate 2. The push rod 3 is a screw rod and is threadedly connected to the corner 1a of the inner angle-shaped bent plate 1 . Push rod 3 adopts screw rod, can regulate pressure conveniently.

[0013] The angle 1a o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com