Process for processing instant tea with high content of ester-type catechin

A processing technology and instant tea ester technology, which is applied in the field of processing technology to increase the content of instant tea ester catechins, can solve the problems of improving instant tea ester catechins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Processing raw materials: finished oolong tea (Dan Cong).

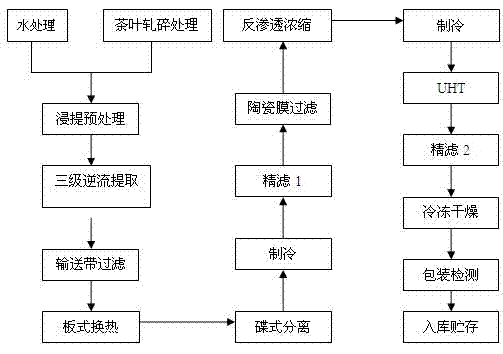

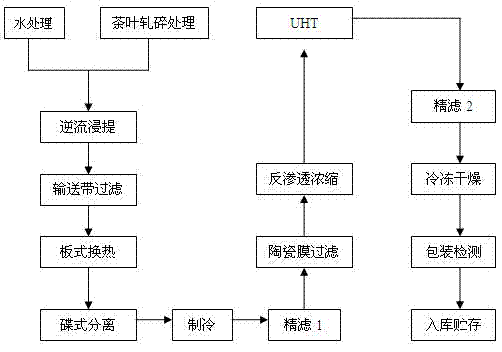

[0044] Process:

[0045] (1) Water treatment: The treated water is ≤1 deg, colorless, odorless and free of visible impurities, and the pH value is controlled at 6.5-7.5.

[0046] (2) Crushing treatment: crush the oolong tea raw material and pass through a 60-mesh sieve.

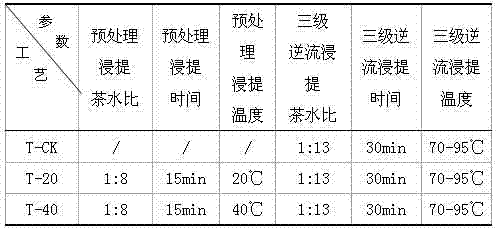

[0047] (3) Countercurrent extraction: raw material 500kg / batch, the first extraction temperature is 20°C or 40°C, the extraction time is 15min, the ratio of tea to water is 1:8, the tea residue is retained after filtration, and the tea residue is extracted for the second time (three-stage Countercurrent extraction), using a countercurrent extraction processor, the second extraction temperature is 90°C, the extraction time is 30 minutes, and the tea water ratio is 1:13; three-stage countercurrent extraction is used to obtain the extract.

[0048] (4) Conveyor belt filtration: pass through a 160-mesh filter.

[0049] (5) Plate heat exchange: ...

Embodiment 2

[0063] Processing raw materials: finished black tea (Fuding Dabai tea).

[0064] Process:

[0065] (1) Water treatment: The treated water is ≤1 deg, colorless, odorless and free of visible impurities, and the pH value is controlled at 6.5-7.5.

[0066] (2) Crushing treatment: crush the black tea raw material and pass through a 60-mesh sieve.

[0067] (3) Countercurrent extraction: raw material 500kg / batch, the first extraction temperature is 20°C or 40°C, the extraction time is 15min, the ratio of tea to water is 1:8, the tea residue is retained after filtration, and the tea residue is extracted for the second time (three-stage Countercurrent extraction), the second extraction temperature is 90-95°C, the extraction time is 30 minutes, and the tea-to-water ratio is 1:13; the third-stage countercurrent extraction is used to obtain the extract.

[0068] (4) Conveyor belt filtration: pass through a 160-mesh filter.

[0069] (5) Plate heat exchange: the temperature after heat ex...

Embodiment 3

[0083] Processing raw materials: finished green tea (Mei Zhan).

[0084] Process:

[0085] (1) Water treatment: The treated water is ≤1 deg, colorless, odorless and free of visible impurities, and the pH value is controlled at 6.5-7.5.

[0086] (2) Crushing treatment: crush the black tea raw material and pass through a 60-mesh sieve.

[0087] (3) Countercurrent extraction: raw material 500kg / batch, the first extraction temperature is 20°C or 40°C, the extraction time is 15min, the ratio of tea to water is 1:8, the tea residue is retained after filtration, and the tea residue is extracted for the second time (three-stage Countercurrent extraction), the second extraction temperature is 70-75°C, the extraction time is 30 minutes, and the tea-to-water ratio is 1:13; the third-stage countercurrent extraction is used to obtain the extract.

[0088] (4) Conveyor belt filtration: pass through a 160-mesh filter.

[0089] (5) Plate heat exchange: the temperature after heat exchange i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap