Cyclone for realizing solution cavitation and separation and separation method

A cyclone separator and cyclone separation technology, which are applied in cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve the problems of high requirements for semi-permeable membranes, small membrane separation processing capacity, and high costs. To achieve the effect of concentration separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

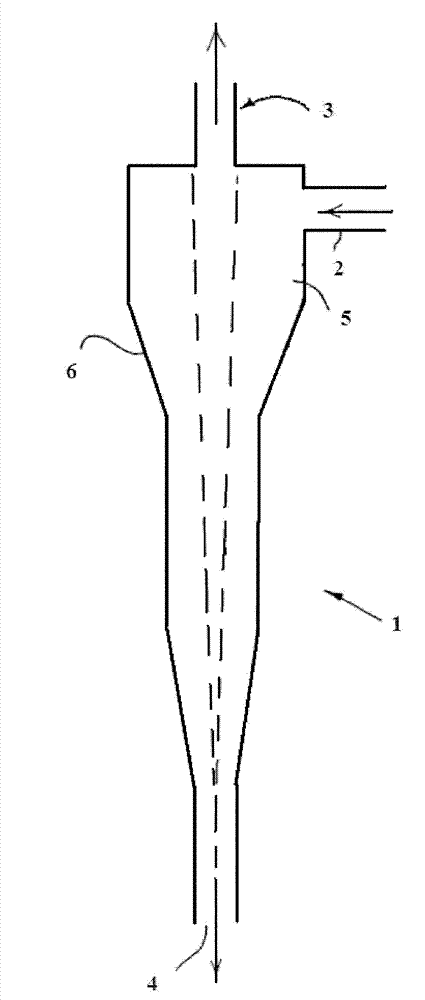

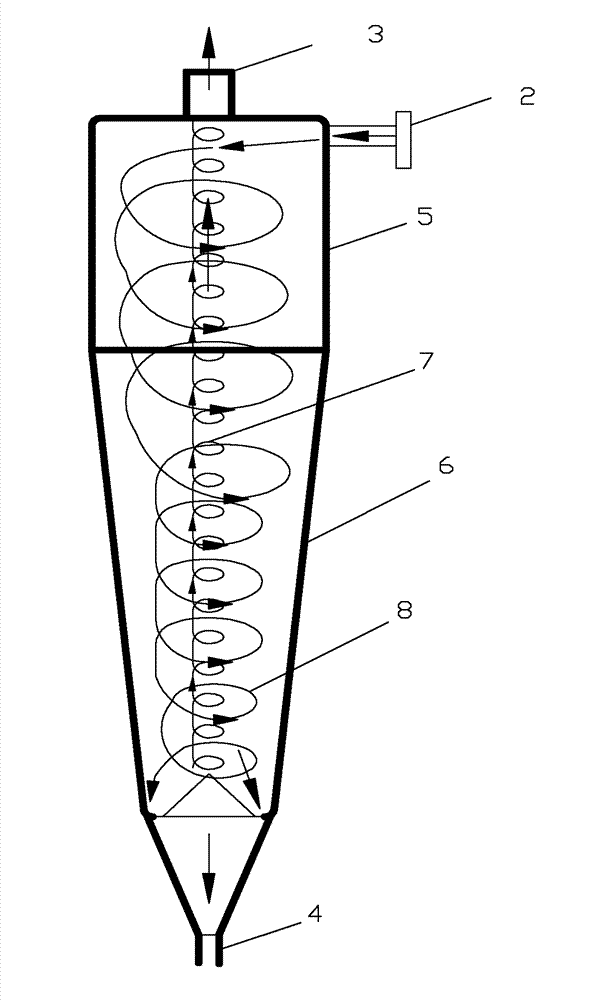

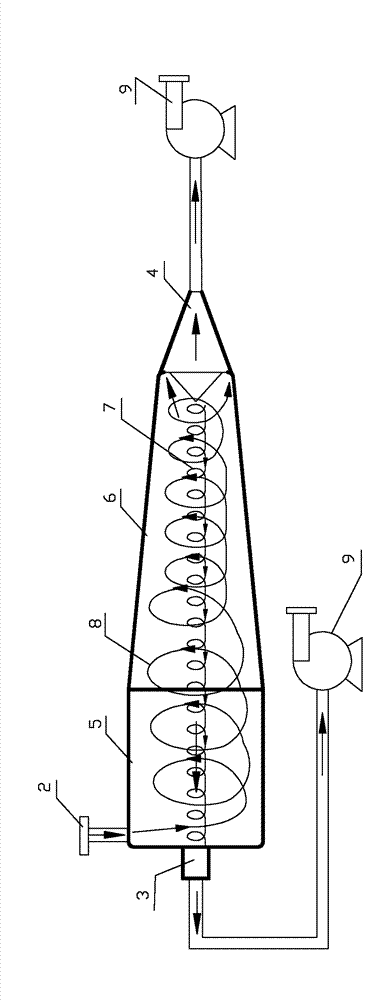

Image

Examples

Embodiment 1

[0034] use figure 2 As shown in the cyclone separator of the present invention, its raw materials and operating conditions are the same as those of the comparative example. After a period of stable operation, it is tested that, typically, the salt content of seawater obtained from outlet b is 43.4‰, and the salt content of liquid obtained from outlet a is 1.5‰.

[0035] Comparing the examples of the present invention with the comparative examples, it can be seen that the cyclone separator of the present invention realizes the separation of miscible substances, while the cyclone separator of the prior art cannot separate miscible substances. Unfavorable technical effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com