Bridge expansion joint with multidirectional displacement function

A multi-directional displacement and telescopic device technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as damage, structural and performance defects, and achieve the effect of eliminating warped teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

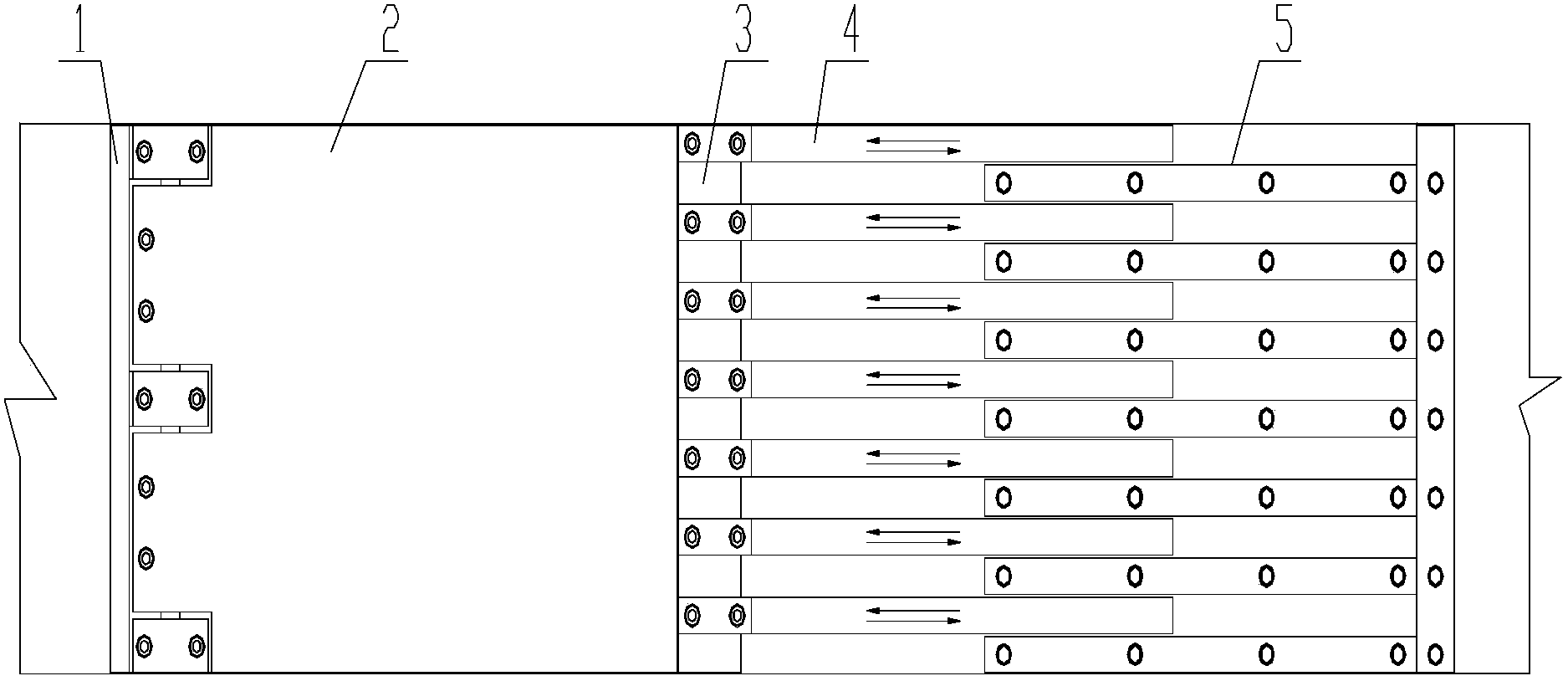

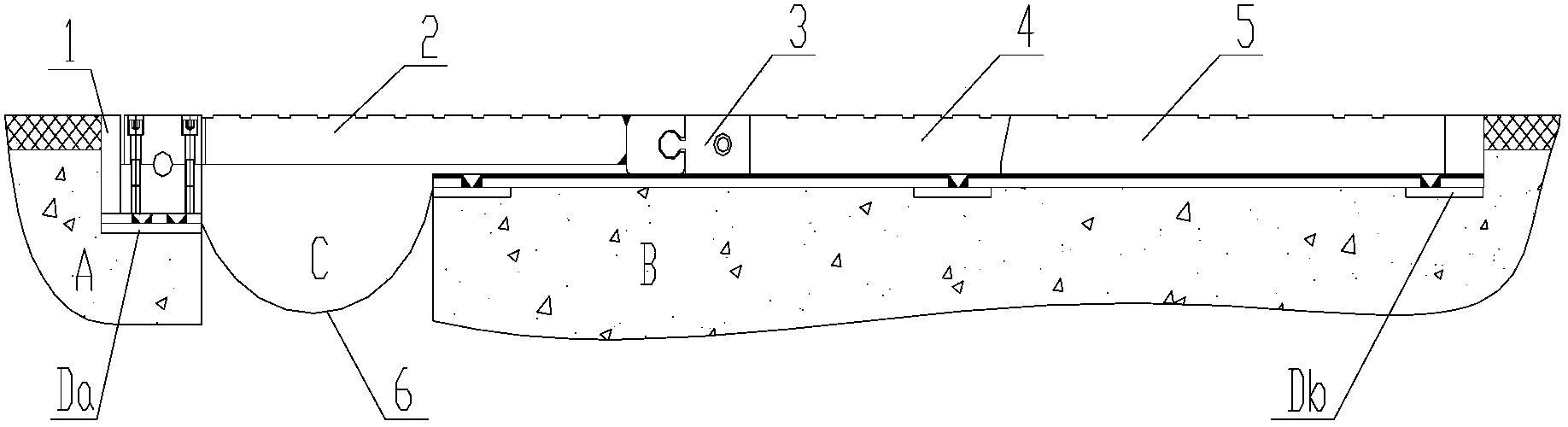

[0028] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

[0029] This device is set for the gap C between two adjacent beams A and B of the bridge, and the embedded steel plates Da and Db are respectively arranged at the end of the gap C between the two adjacent beams A and B,

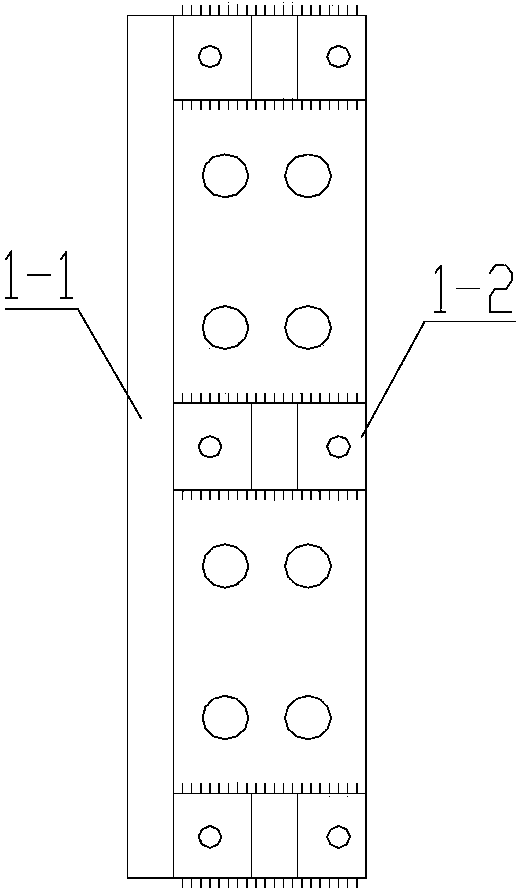

[0030] The device consists of a mounting base, a water stop, a movable telescopic comb connection unit, and a fixed comb connection unit. The installation base 1 is composed of a base 1-1 and a rotating shaft support 1-2 welded (such as image 3 As shown), the installation base 1 is directly welded on the embedded steel plate Da, and the fixed comb connection unit 5 is composed of a low-friction shock-absorbing bottom plate 5-1, a fixed comb body 5-2, and a baffle 5-3. The plate 5-3 is fixedly connected to one end of the low-friction shock-absorbing bottom plate 5-1, and the fixed comb body 5-2 is installed on the low-friction shock-absorbing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com