Patents

Literature

30results about How to "Meet the needs of miniaturization design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

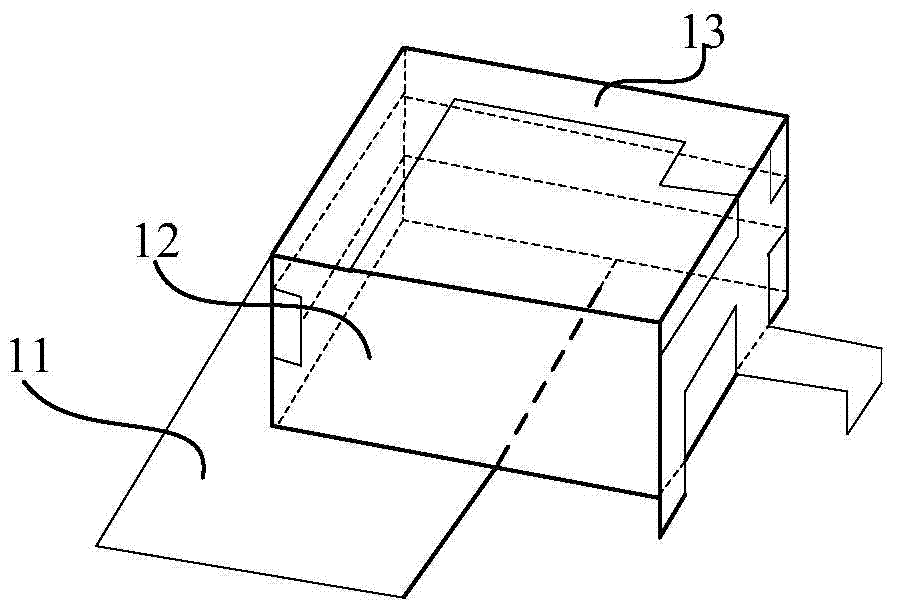

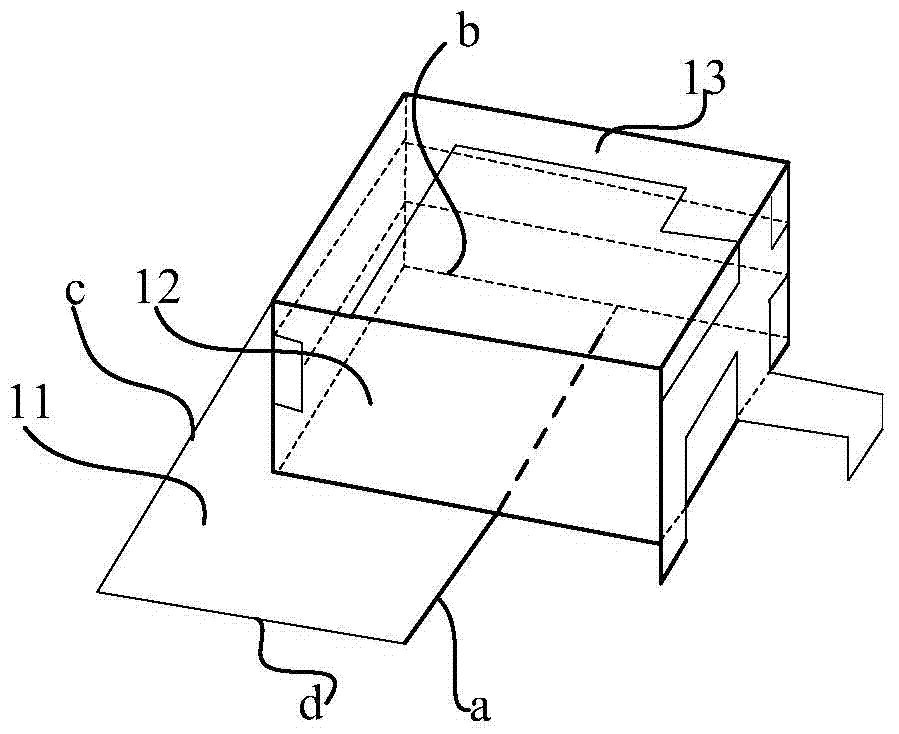

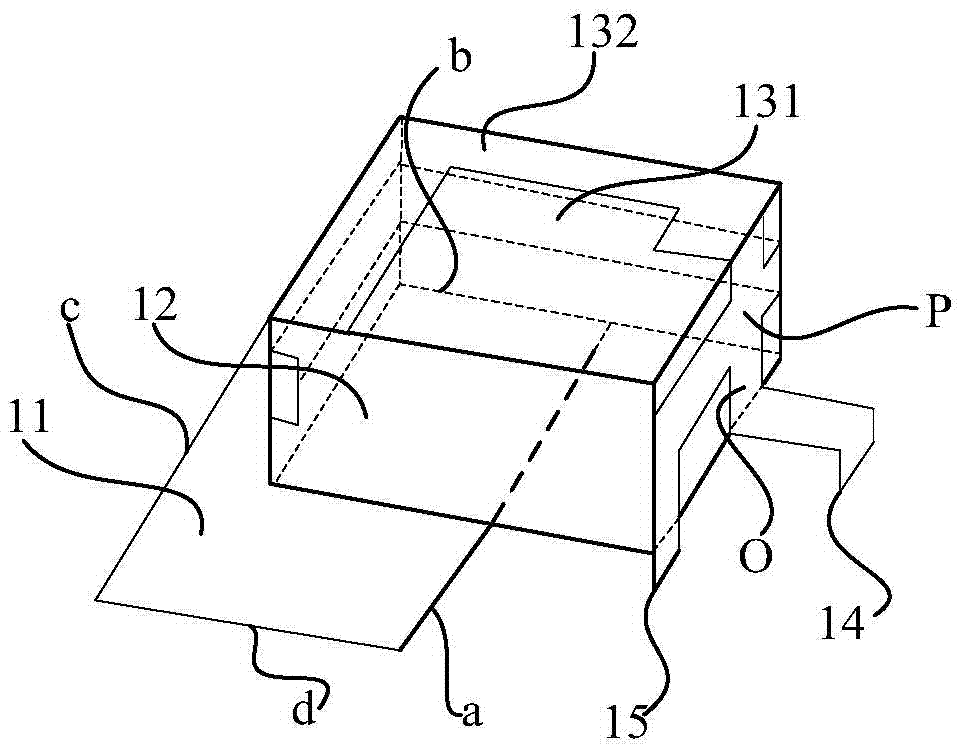

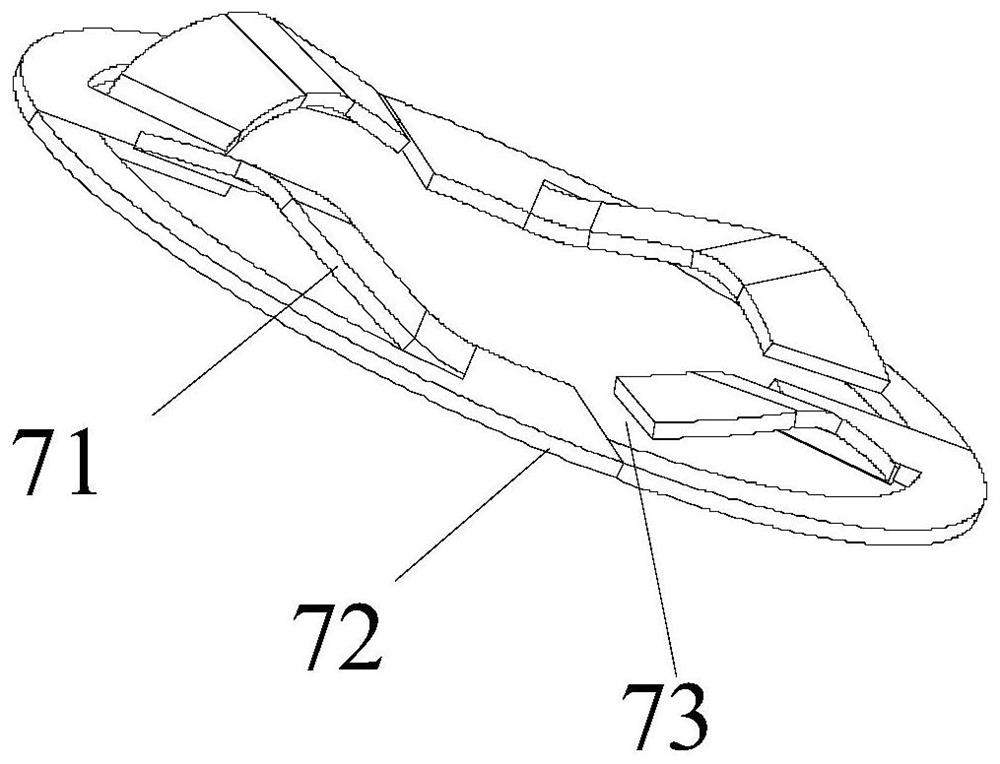

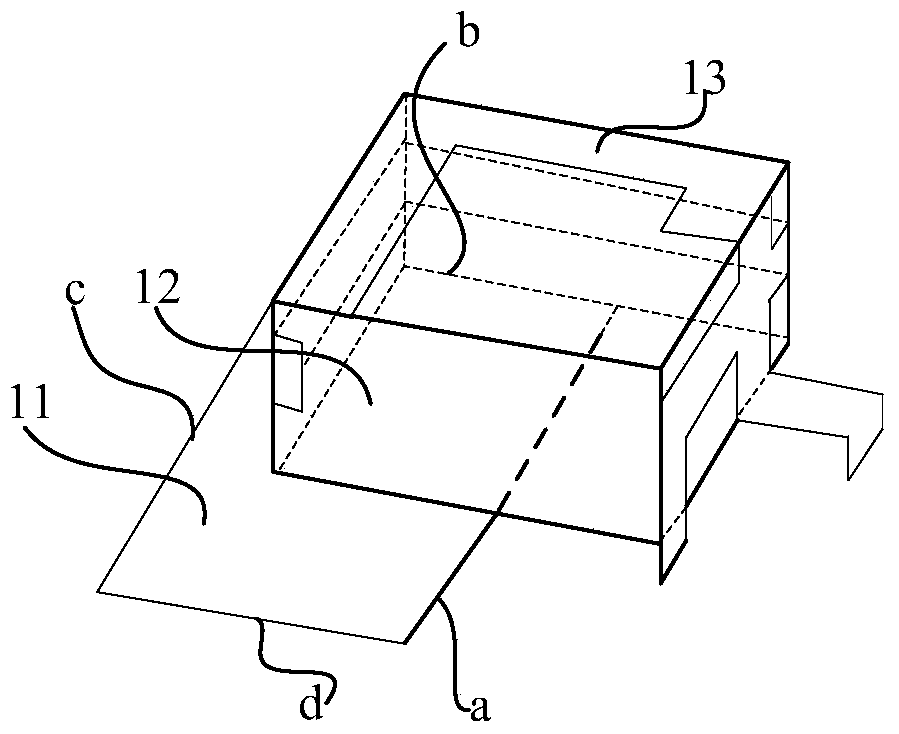

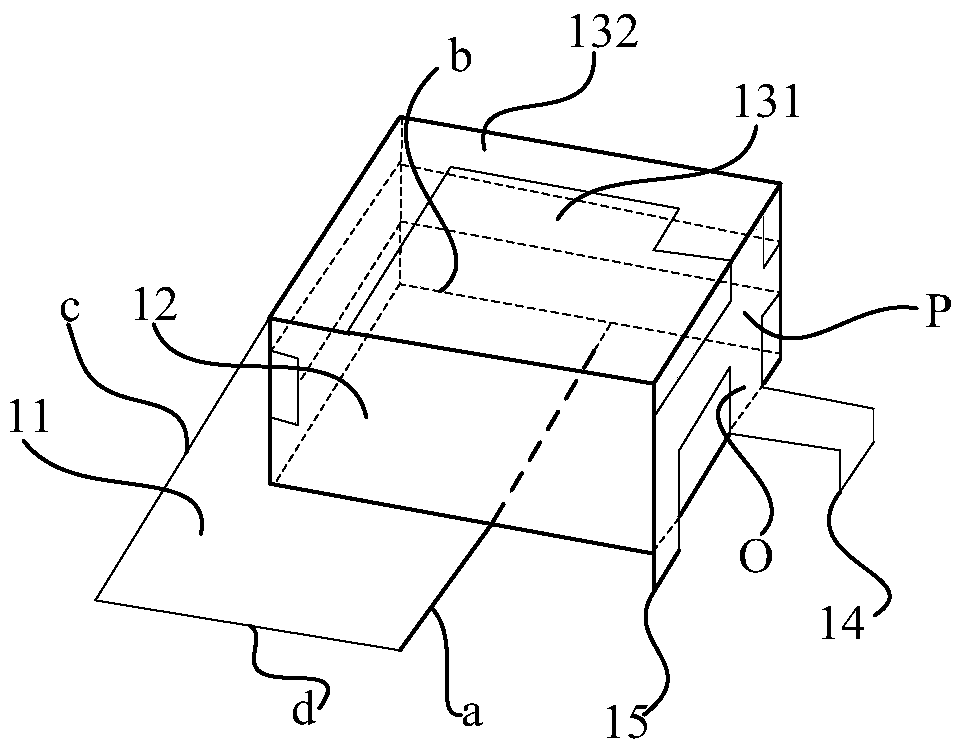

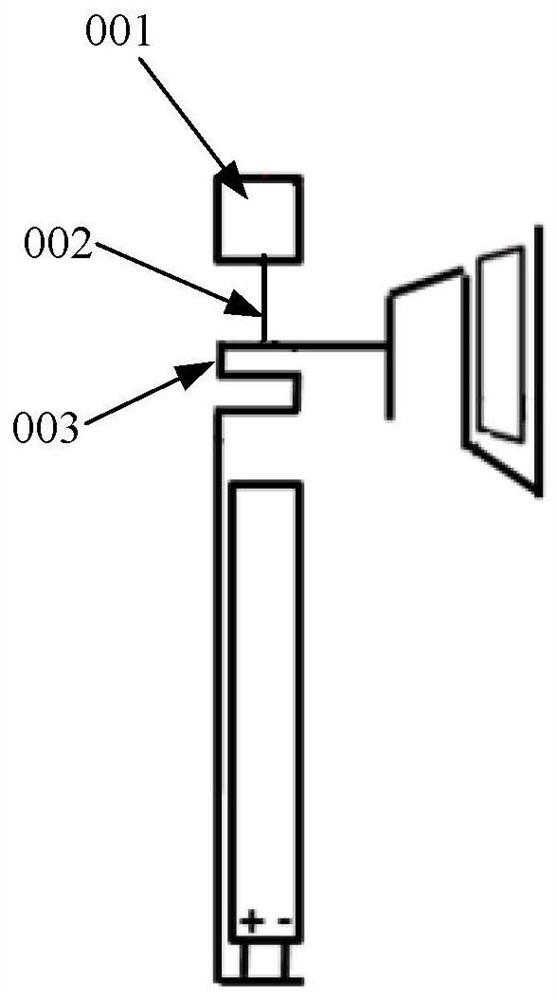

Antenna unit, MIMO (Multiple-Input Multiple-Output) antenna and terminal

ActiveCN106935960ASmall sizeMiniaturizationSimultaneous aerial operationsRadiating elements structural formsTelecommunicationsMimo antenna

The invention relates to the technical field of communication, and particularly relates to an antenna unit, a MIMO (Multiple-Input Multiple-Output) antenna and a terminal. The antenna unit can realize miniaturization while multiband operation is realized, and when the antenna unit is applied to the MIMO antenna, the size of the MIMO antenna can be reduced, and when the MIMO antenna is applied to the terminal, the miniaturization design demands of the terminal can be met. The antenna unit provided by the embodiment of the invention comprises a clearance area, a support and at least two branches, wherein each branch is arranged on the support; part of the projection of the support on the horizontal plane falls in the clearance area; and the projection of one end for connecting a feed point of each branch on the horizontal plane is located outside the clearance area, and the projection of the tail end on the horizontal plane is located inside the clearance area.

Owner:HUAWEI TECH CO LTD

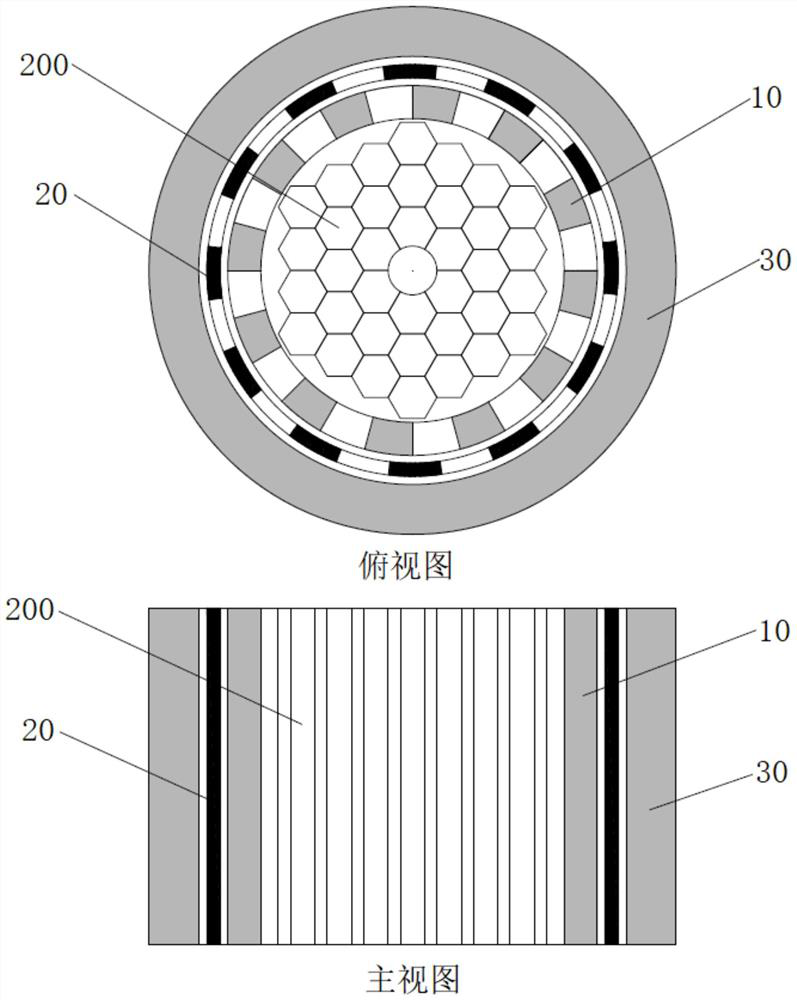

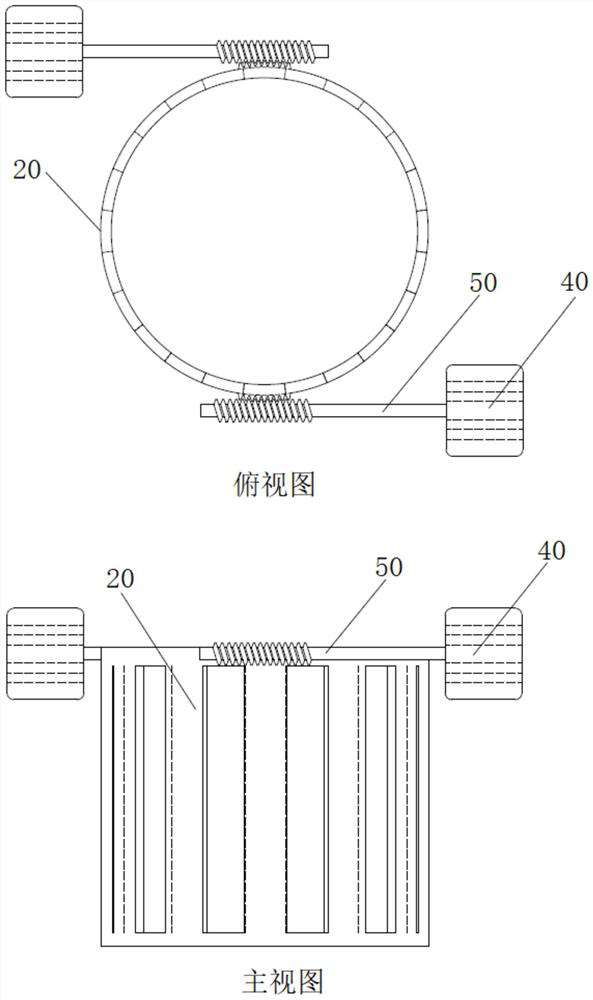

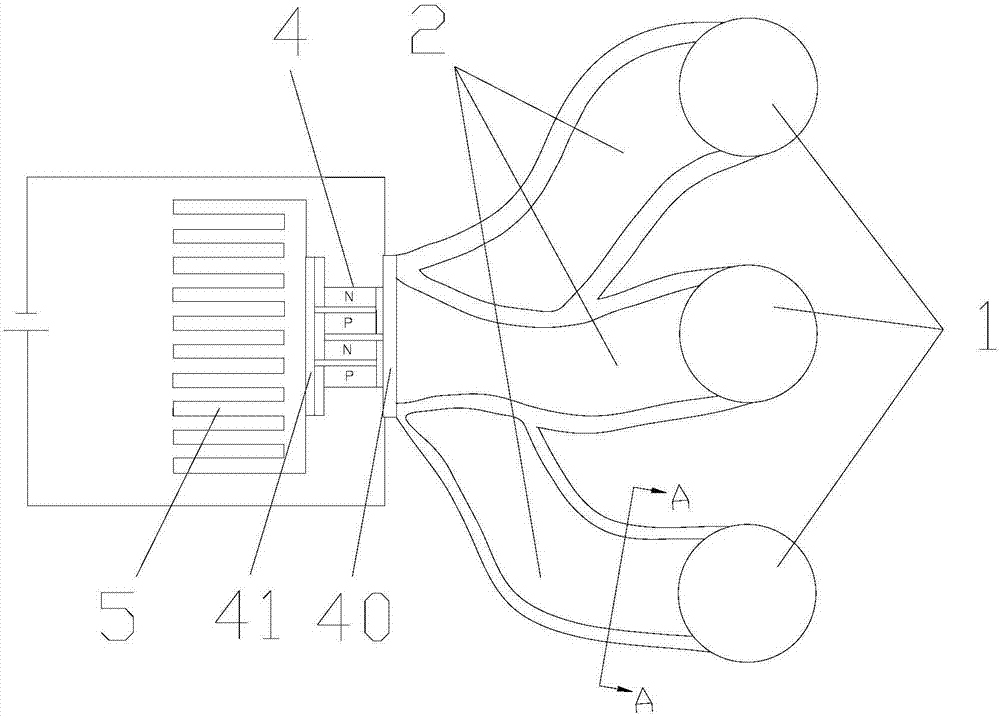

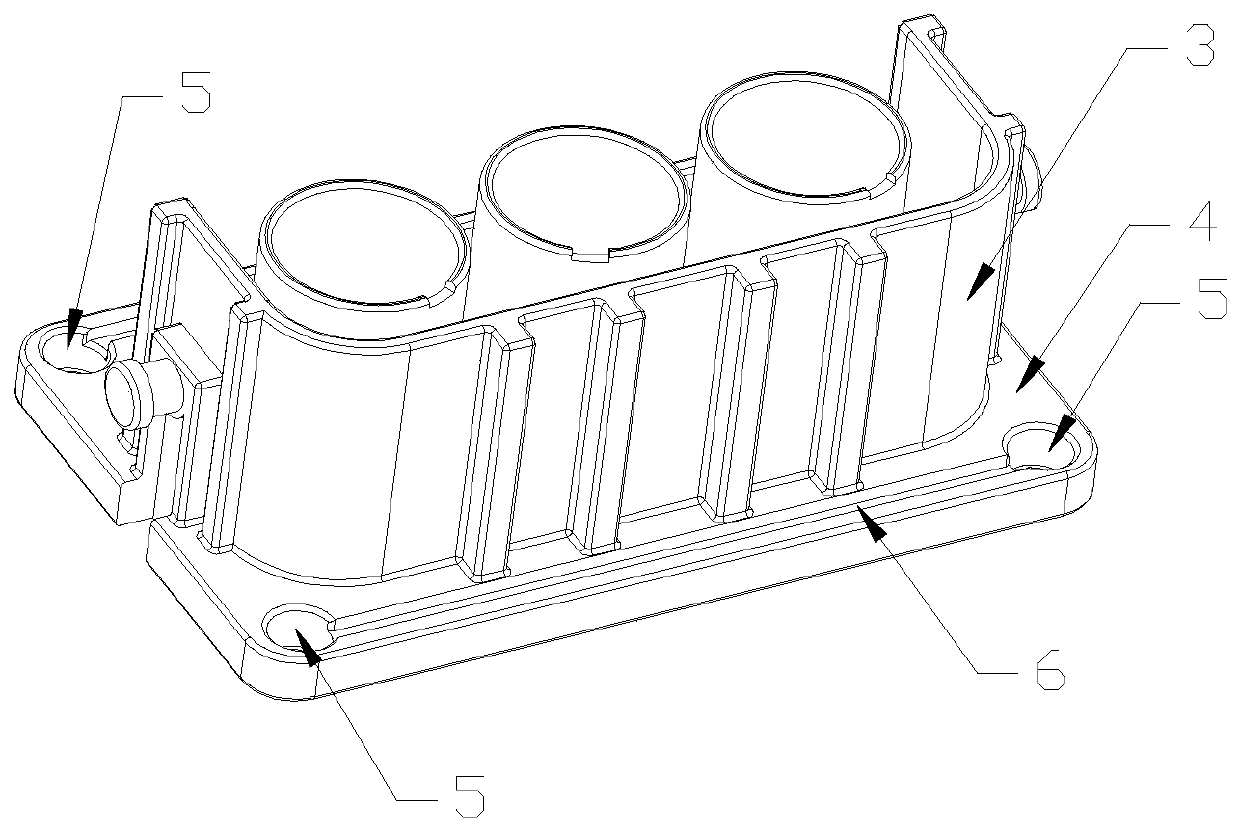

Grid type control drum device of small fast neutron reactor

ActiveCN112037937AChange quantityEasy to controlNuclear energy generationNuclear reaction controlAxial displacementNeutron count

The invention relates to a grid type control drum device of a small fast neutron reactor. The grid type control drum device comprises an inner reflecting layer, a grid type control drum and an outer reflecting layer which sequentially sleeve the periphery of a reactor core from inside to outside, and a driving motor for driving the grid type control drum; the inner reflecting layer is in a cylindrical grid shape and is fixed in position; the outer reflecting layer is in a complete cylinder shape and is fixed in position; and the grid type control drum is in a cylindrical grid shape and can bedriven by the driving motor to rotate by a certain angle so as to adjust the overlapping area between the absorption grids and the reflection grid of the inner reflecting layer and change the number of leaked neutrons reflected back to the reactor core, so reactivity control is achieved. The device disclosed by the invention is small in occupied axial space, and meets the miniaturization design requirement; the absorption grids have no axial displacement, so that uneven axial power distribution of the reactor core cannot be caused; and the absorption grids are in central symmetry about the central axis of the reactor core, have good adaptability to material expansion caused by radial temperature gradient, and are not easy to block due to deformation.

Owner:CHINA SHIP DEV & DESIGN CENT

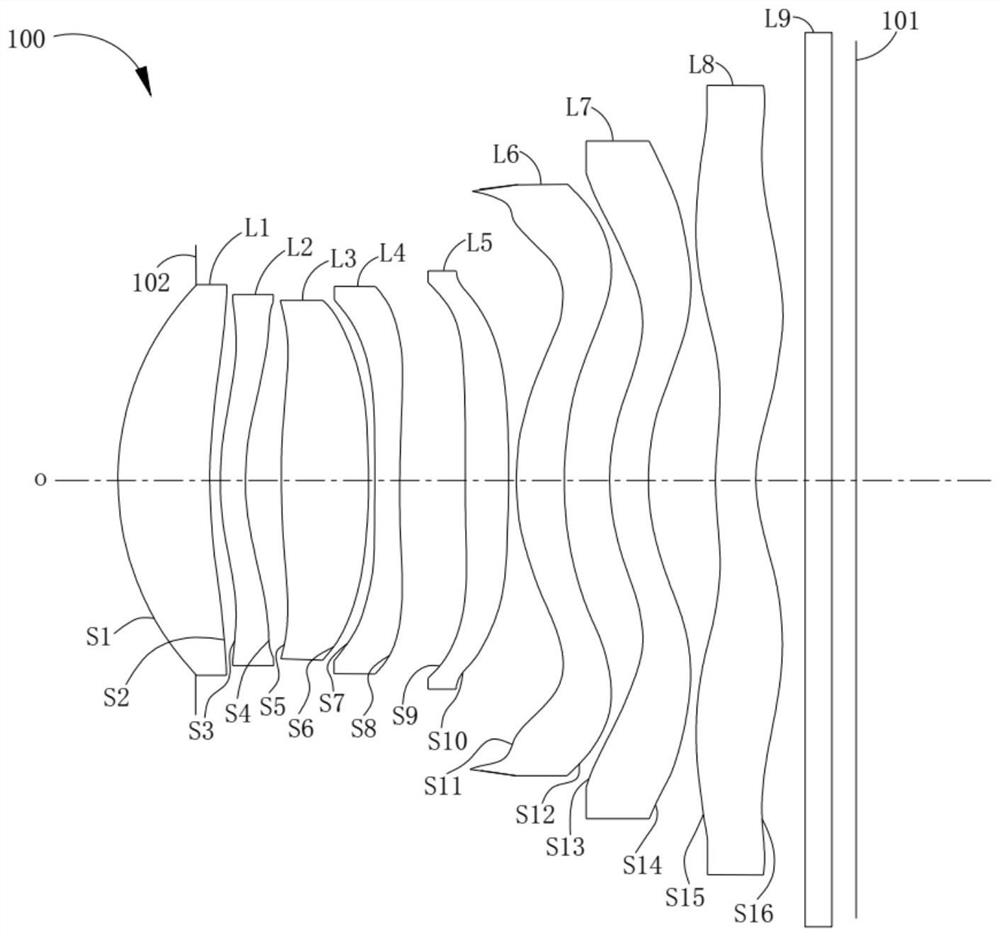

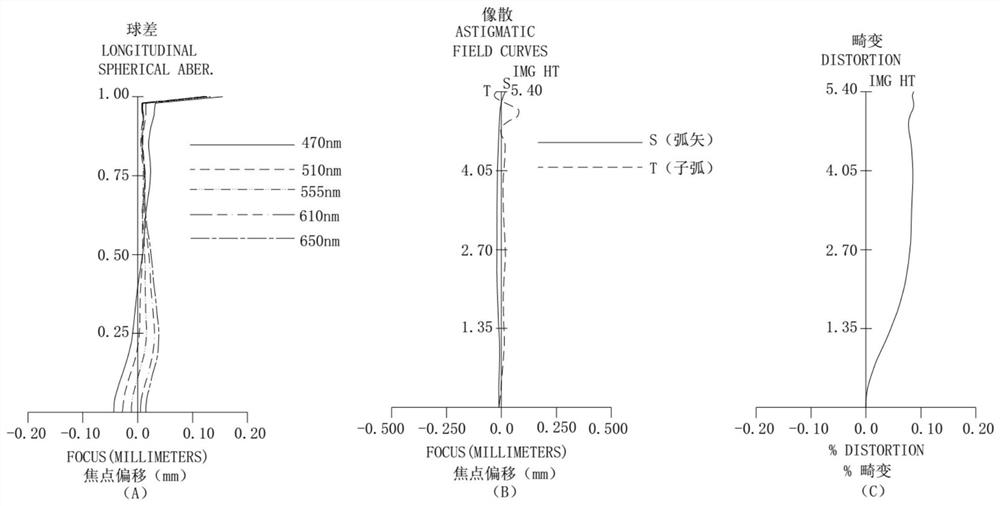

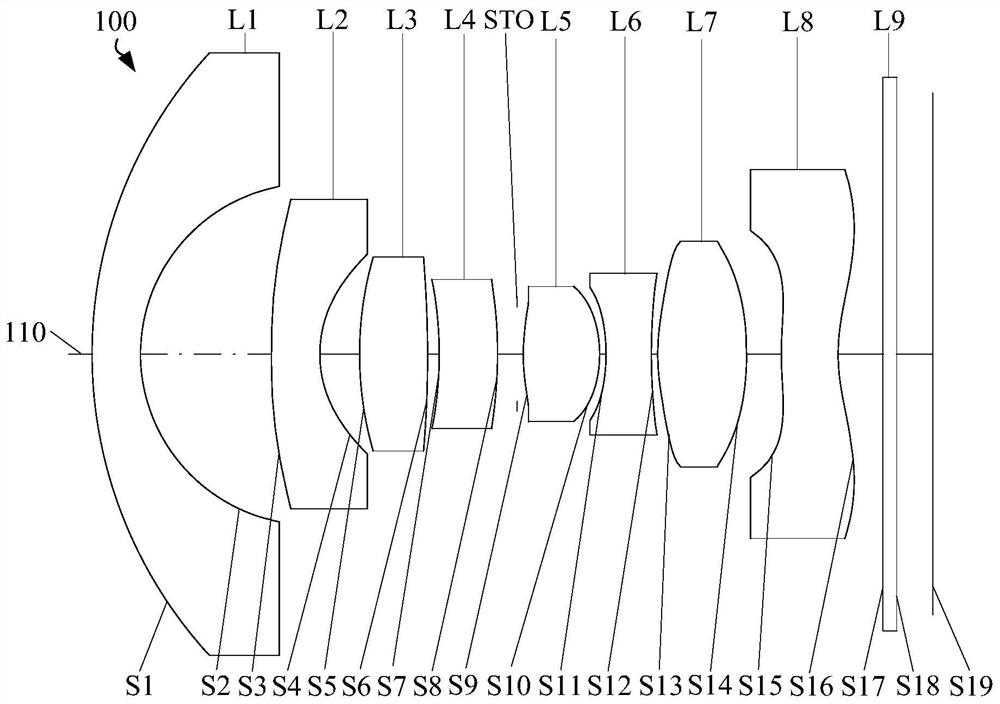

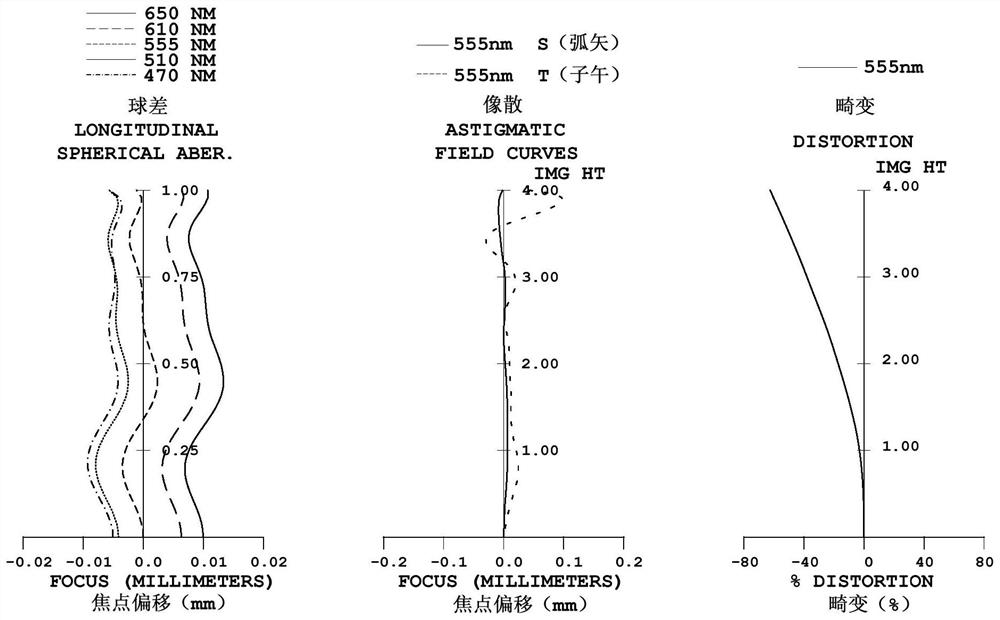

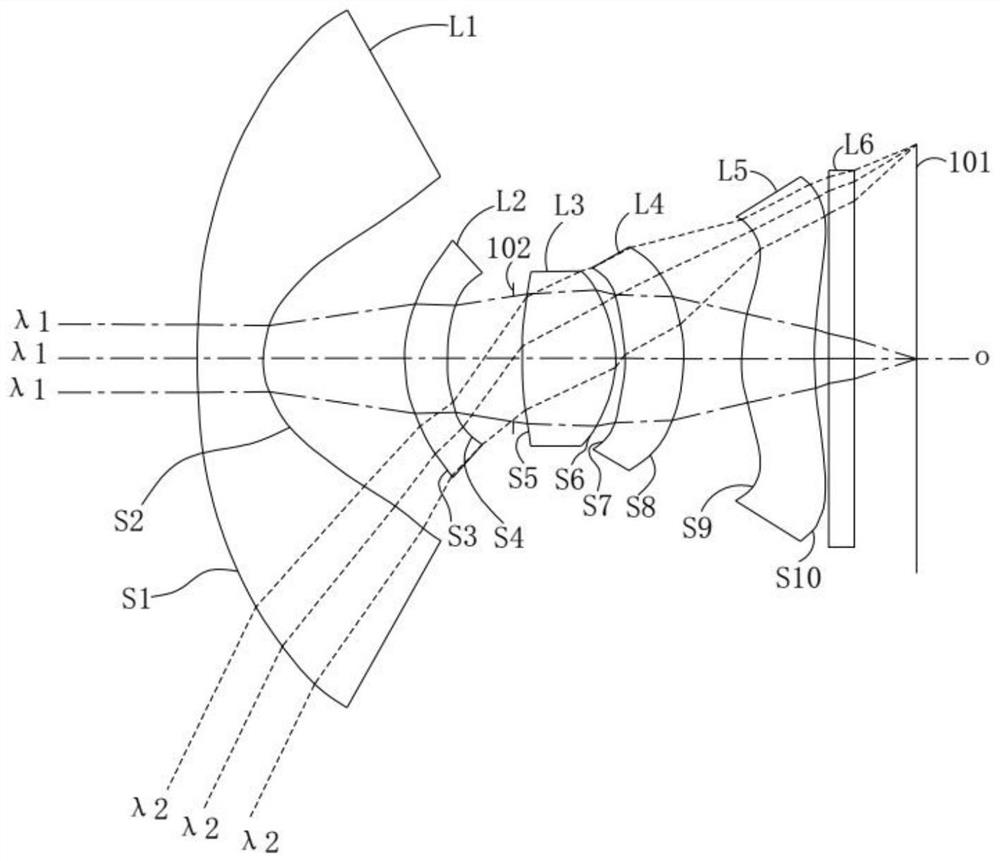

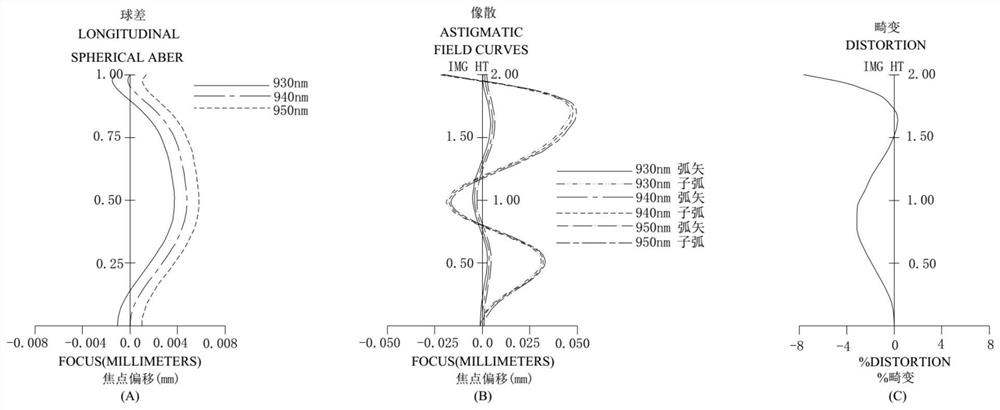

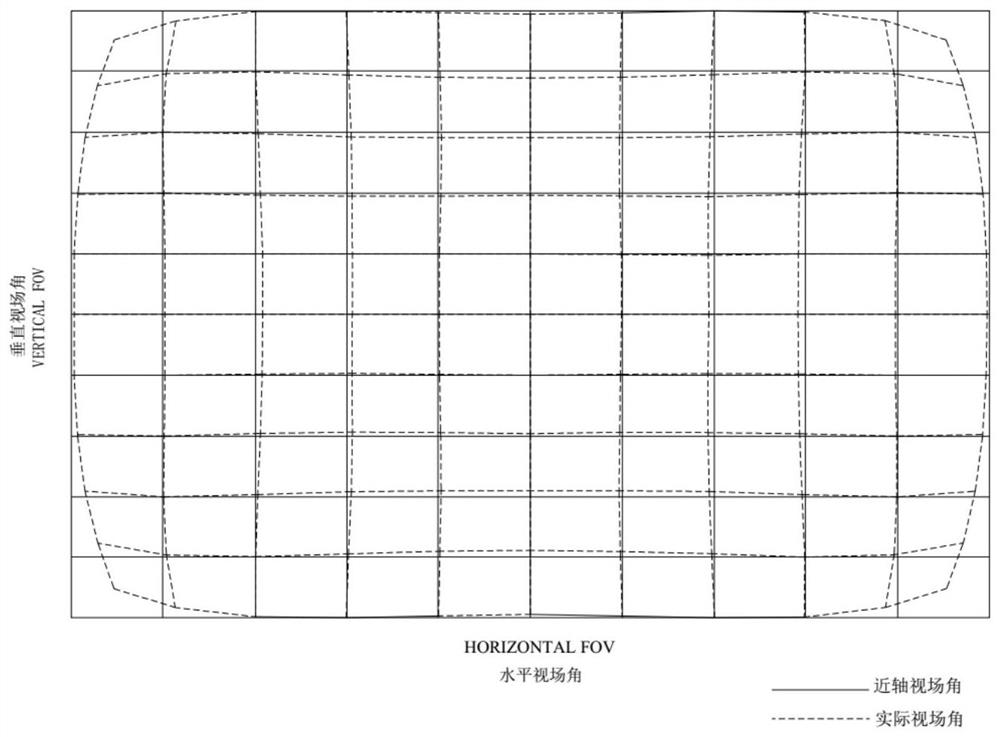

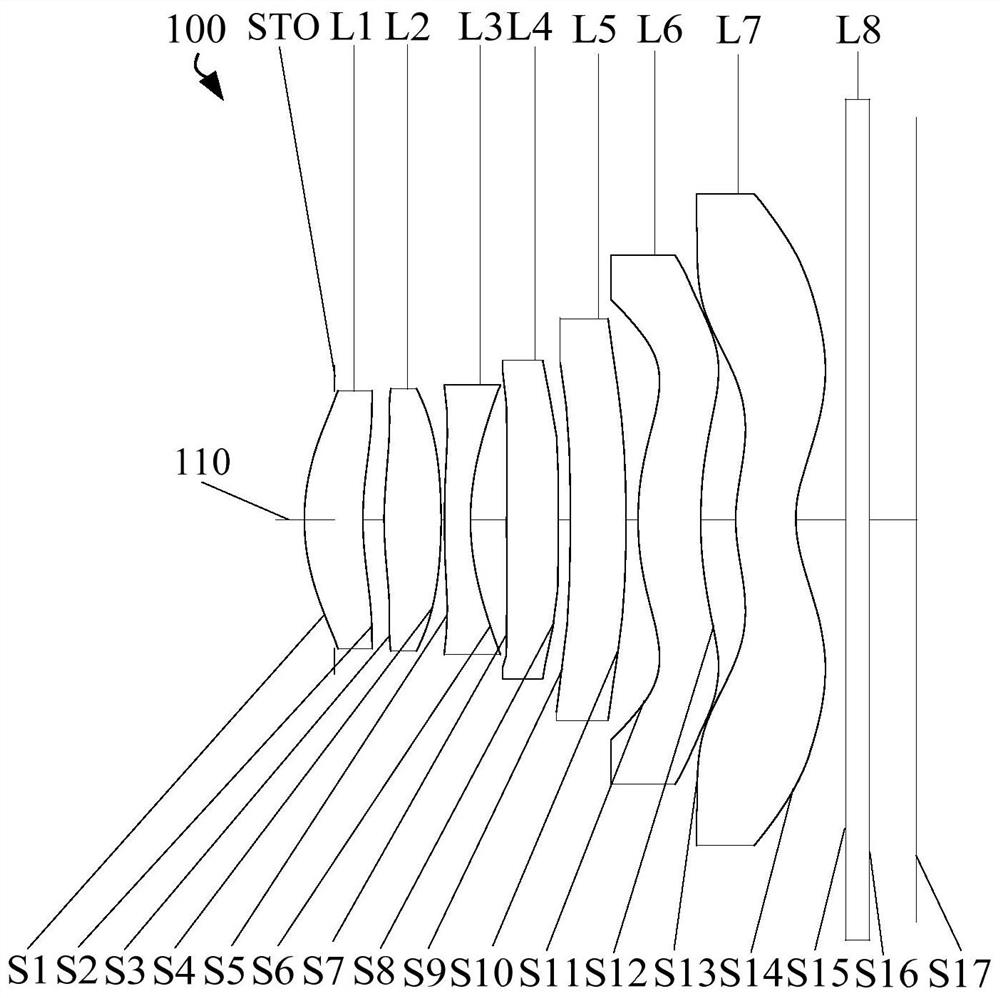

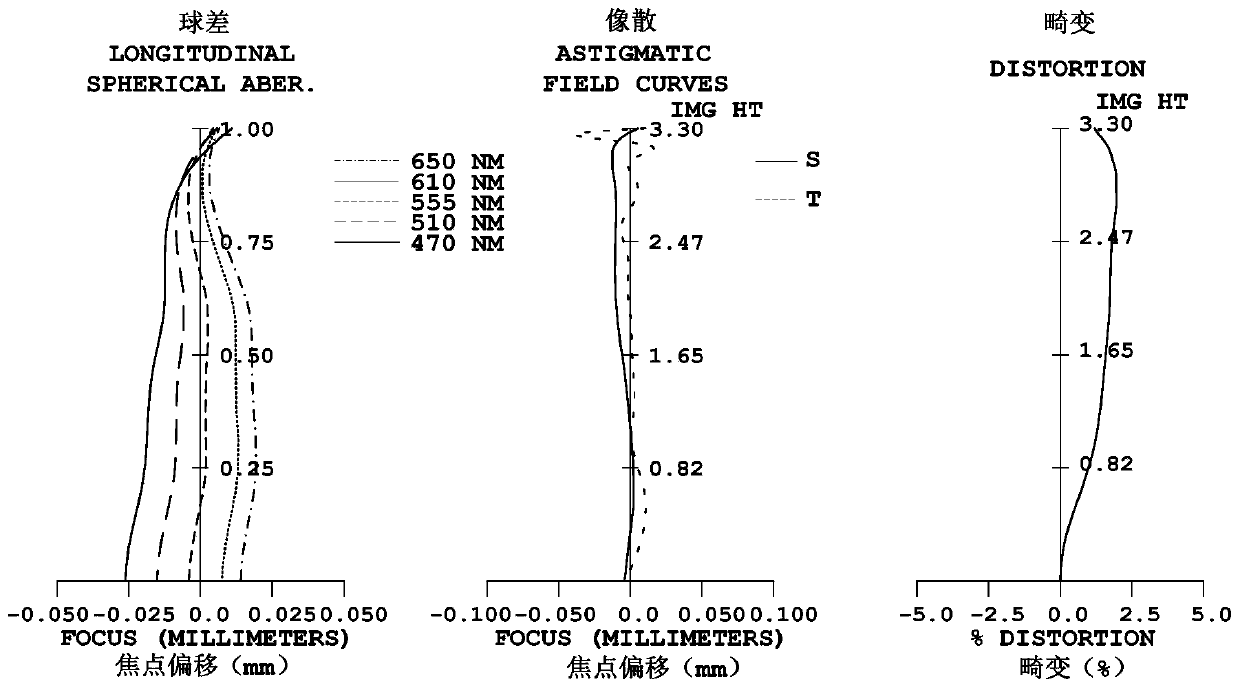

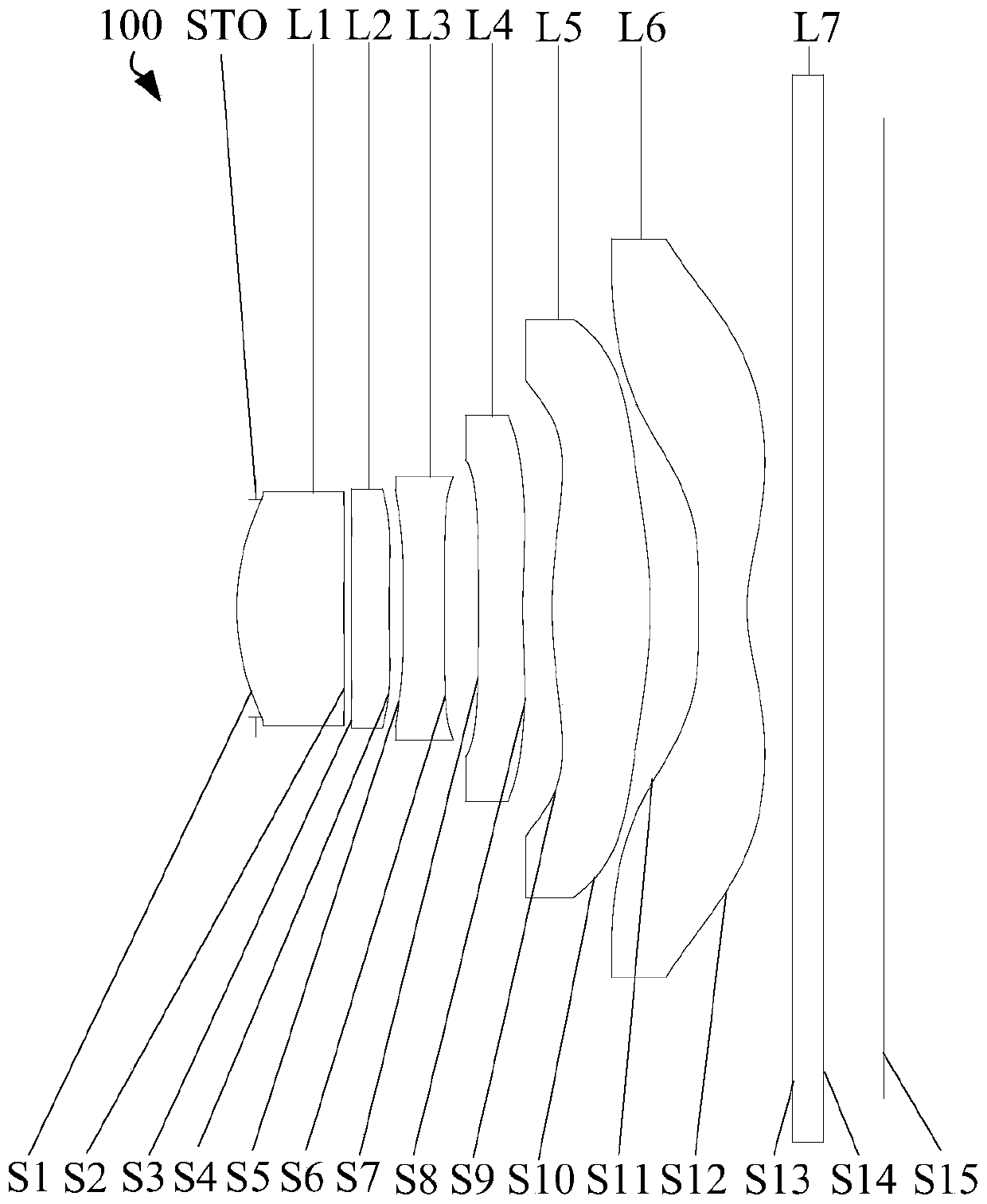

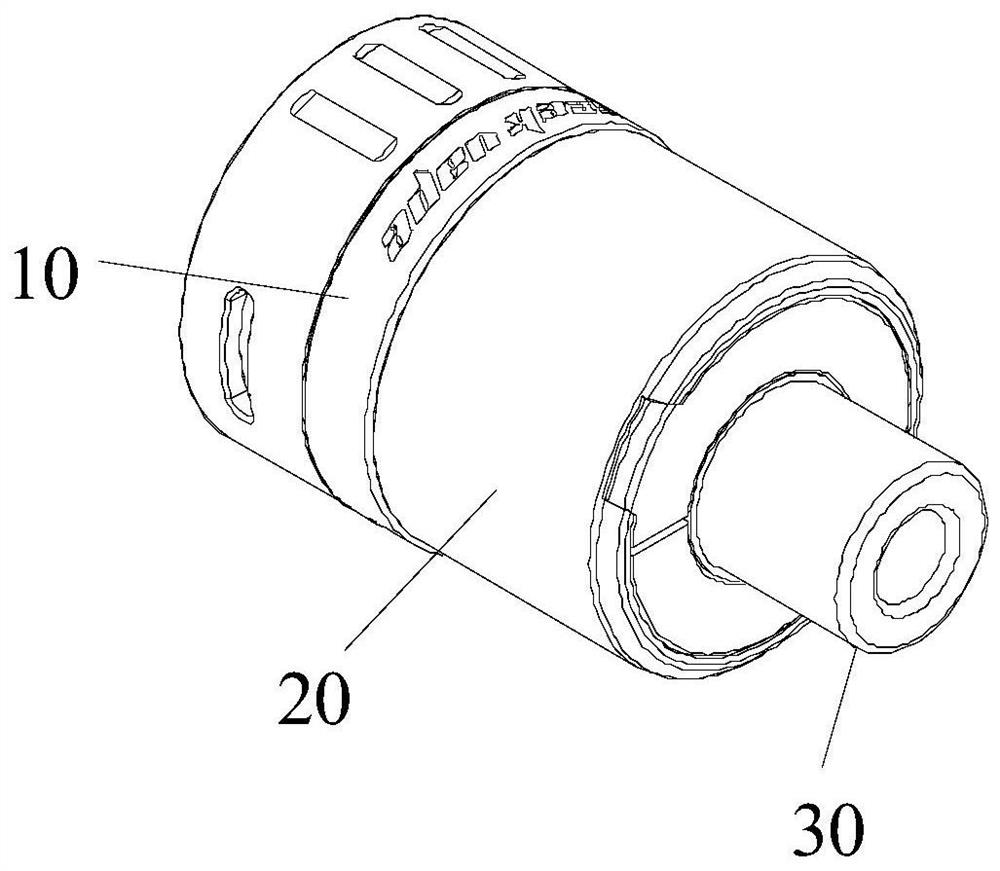

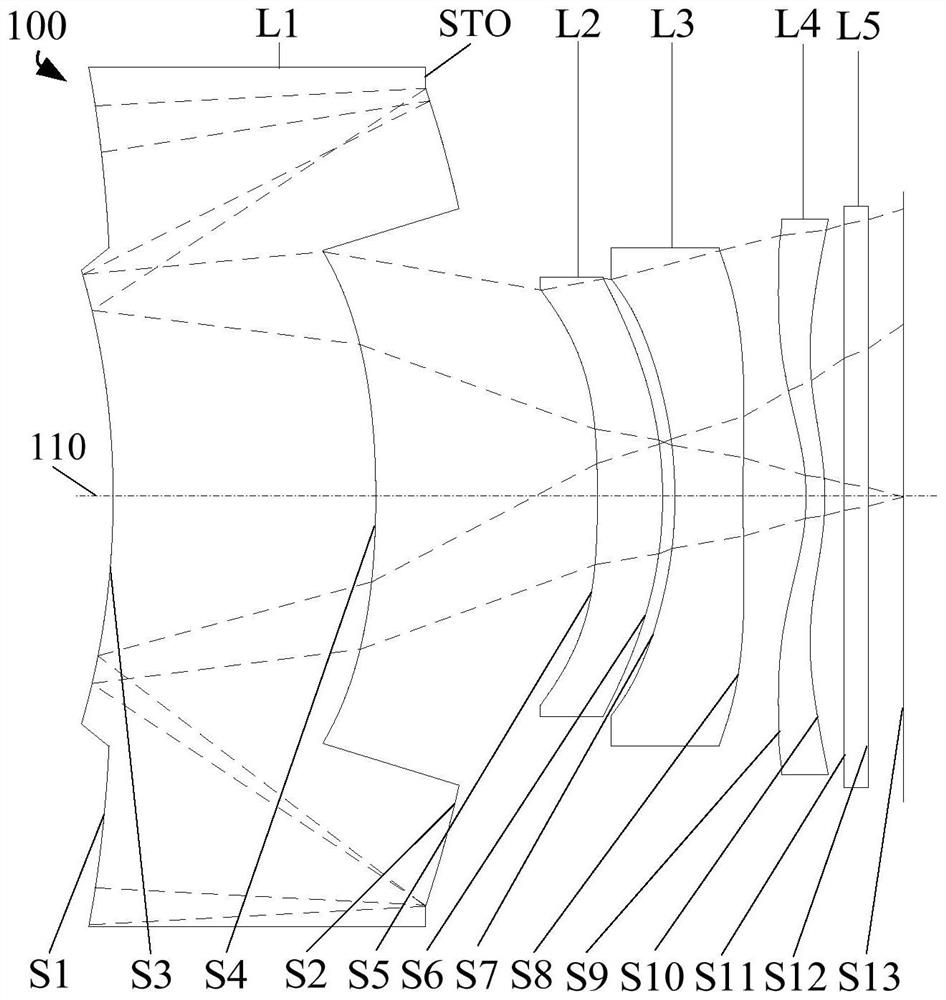

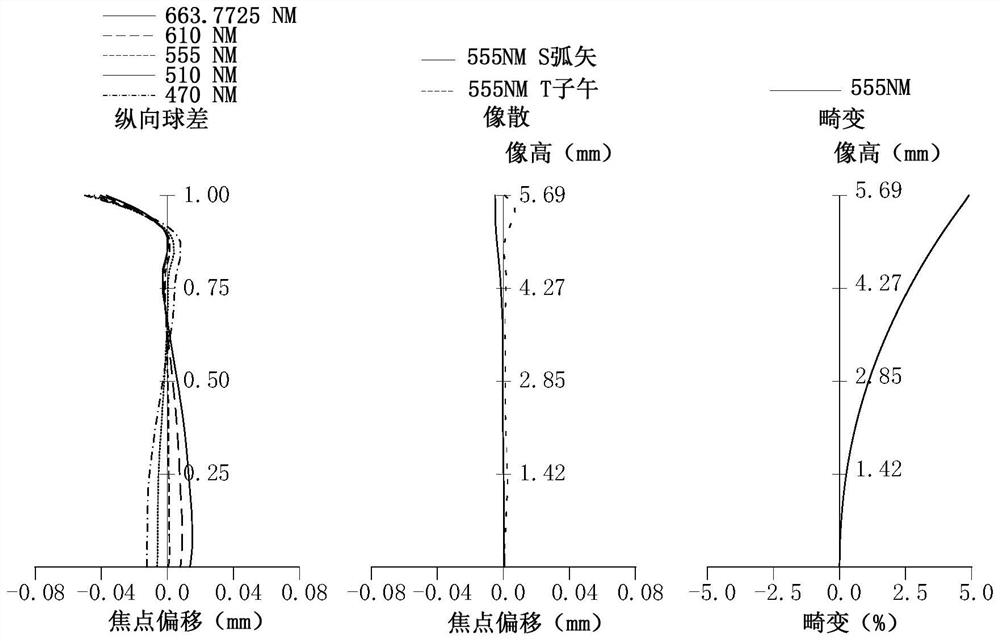

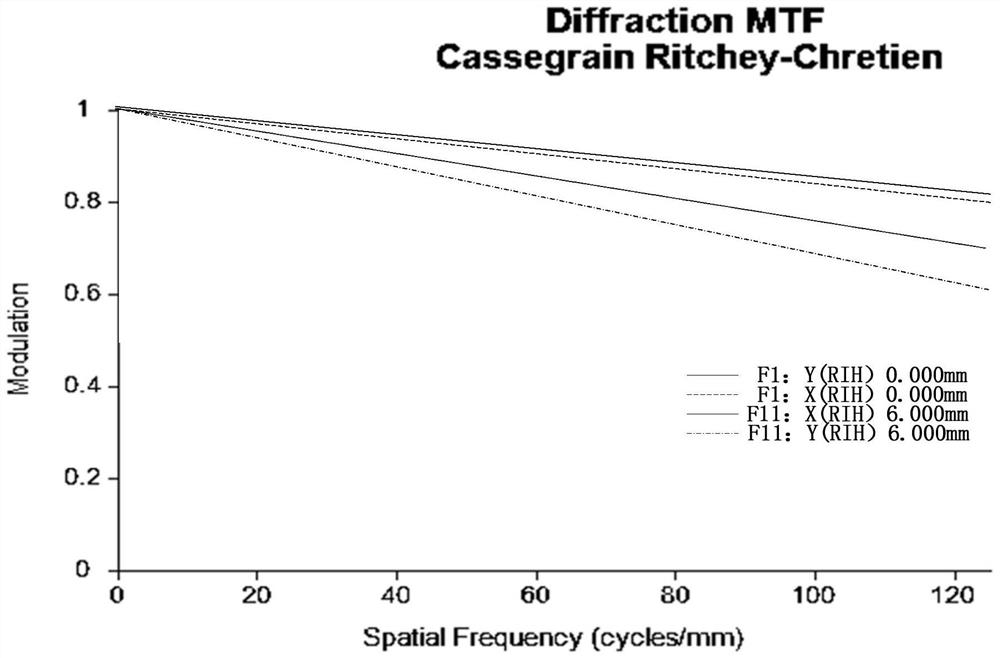

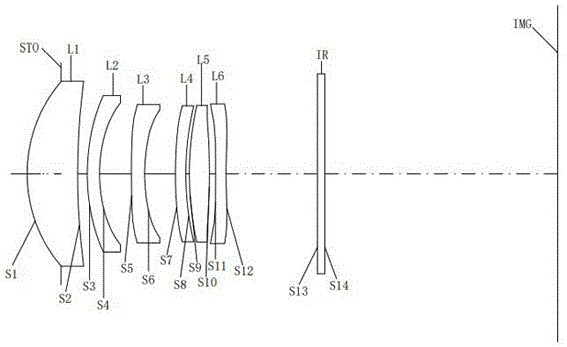

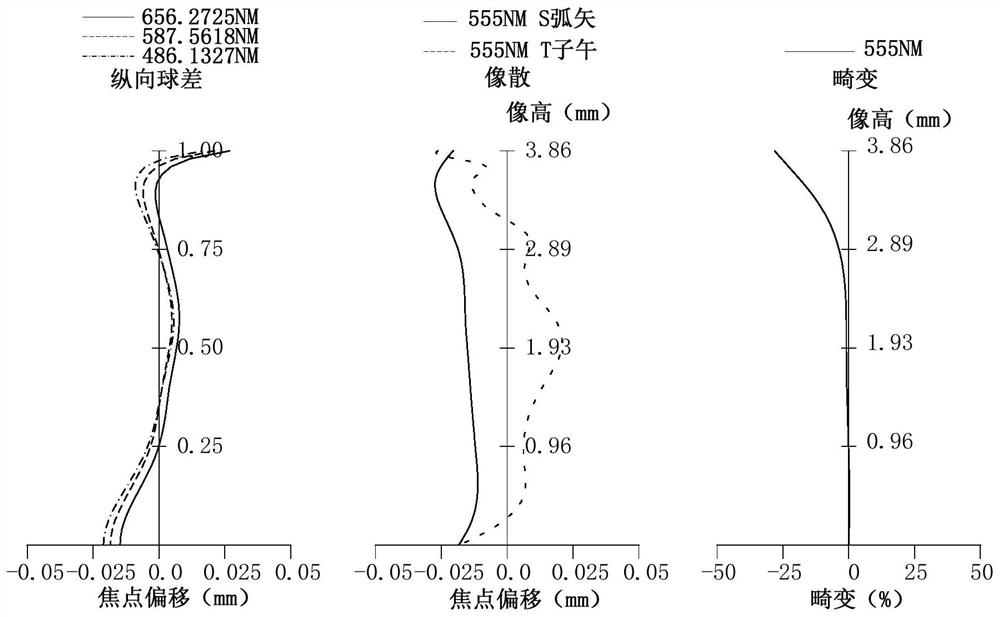

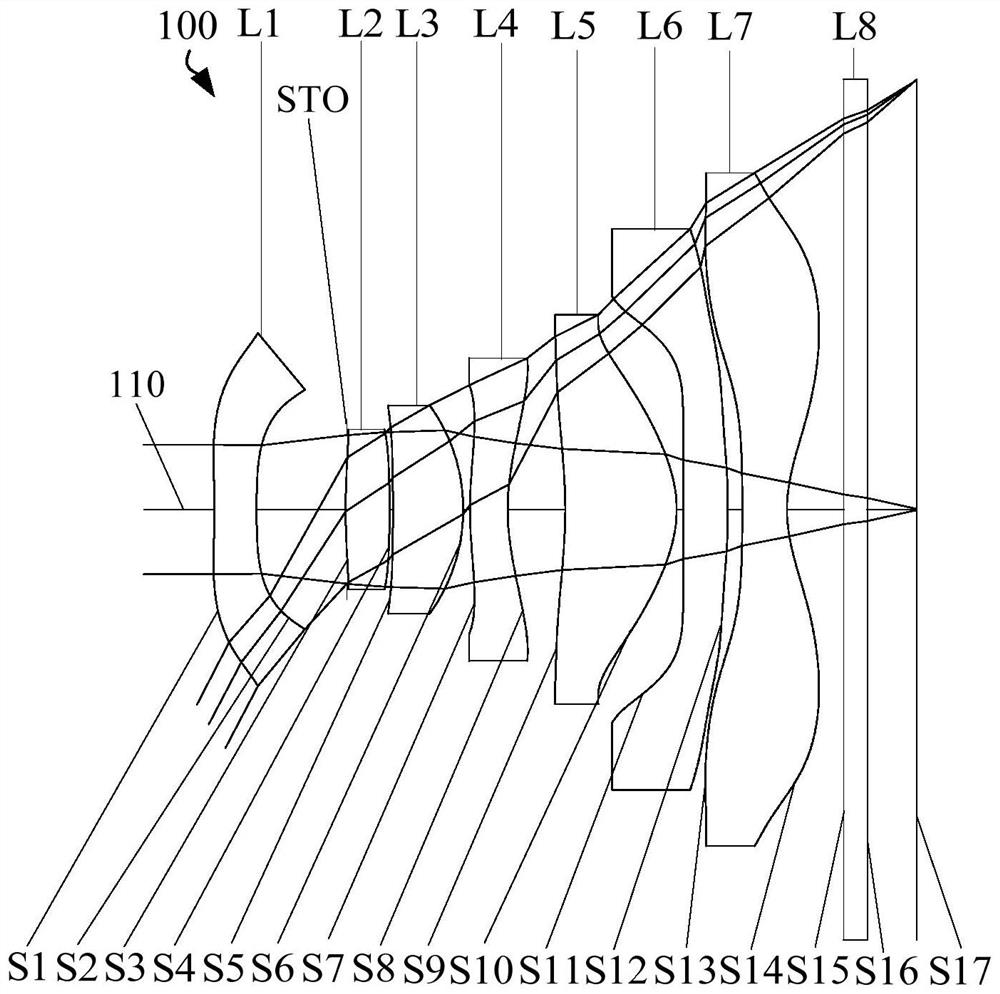

Optical lens, camera module and electronic equipment

ActiveCN113552697AShorten the overall lengthMeet the needs of miniaturization designOptical elementsOphthalmologyOptical axis

The invention discloses an optical lens, a camera module and electronic equipment. The optical lens comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens, a seventh lens and an eighth lens which are sequentially arranged from an object side to an image side along an optical axis. The first lens element with positive refractive power has an object-side surface being convex in a paraxial region and an image-side surface being concave in a paraxial region. The second lens element has an object-side surface being convex in a paraxial region and an image-side surface being concave in a paraxial region. The third lens element with positive refractive power has an image-side surface being convex in a paraxial region thereof. The fourth lens element has negative refractive power. The fifth lens element has an object-side surface being concave in a paraxial region thereof. The sixth lens element has an object-side surface being convex in a paraxial region thereof and an image-side surface being concave in a paraxial region thereof. The seventh lens element has an object-side surface being convex in a paraxial region and an image-side surface being concave in a paraxial region. The eighth lens element with negative refractive power has an object-side surface being convex in a paraxial region thereof and an image-side surface being concave in a paraxial region thereof.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

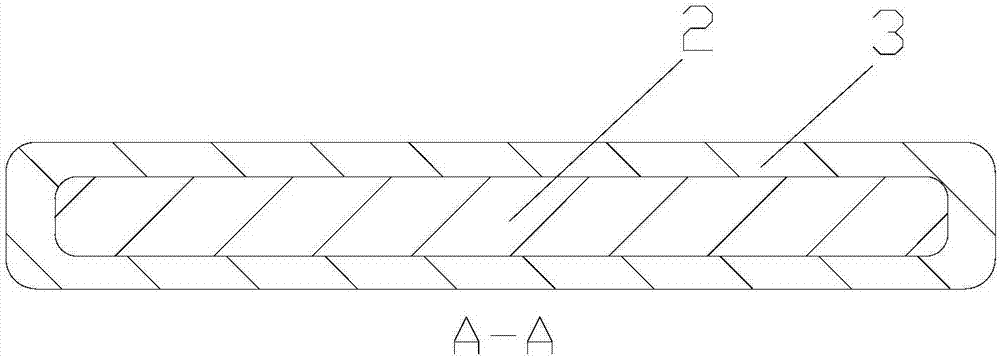

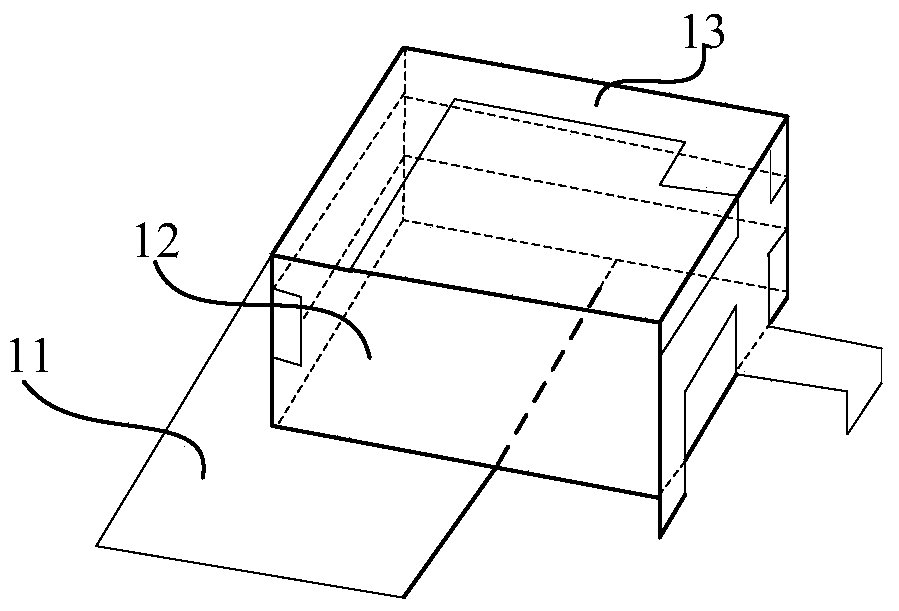

Active heat dissipation mechanism and intelligent wearable equipment

ActiveCN107393891AMeet the needs of miniaturization designSmall footprintSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsMiniaturization

The invention discloses an active heat dissipation mechanism and intelligent wearable equipment. The active heat dissipation mechanism comprises a thermoelectric refrigerating unit, a heat dissipater connected to a thermal terminal of the thermoelectric refrigerating unit, and a heat conduction element. The heat conduction element is configured to conduct heat generated by a plurality of heating elements to a cold terminal of the thermoelectric refrigerating unit. The active heat dissipation mechanism has the following beneficial effects: on the basis of the heat dissipation design, the internal usage space of electronic equipment is saved; and the miniature demand of the electronic equipment is satisfied.

Owner:GEER TECH CO LTD

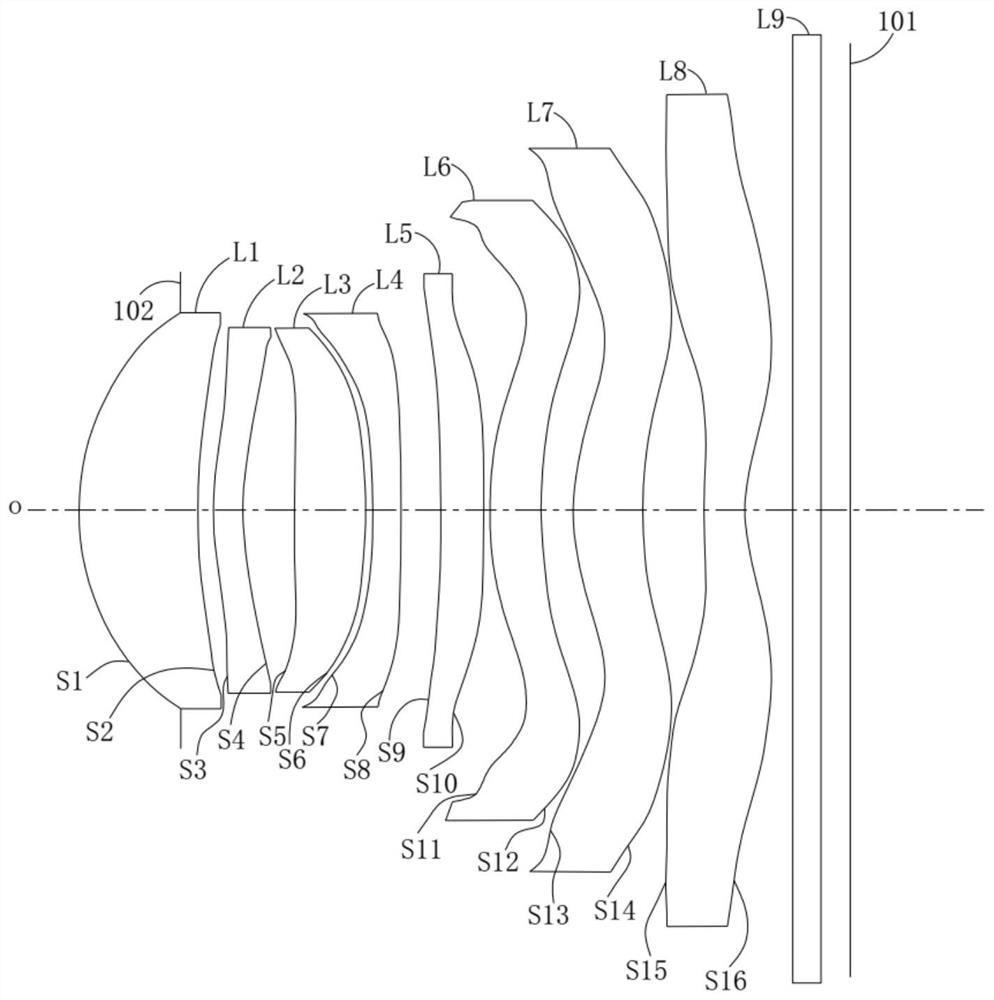

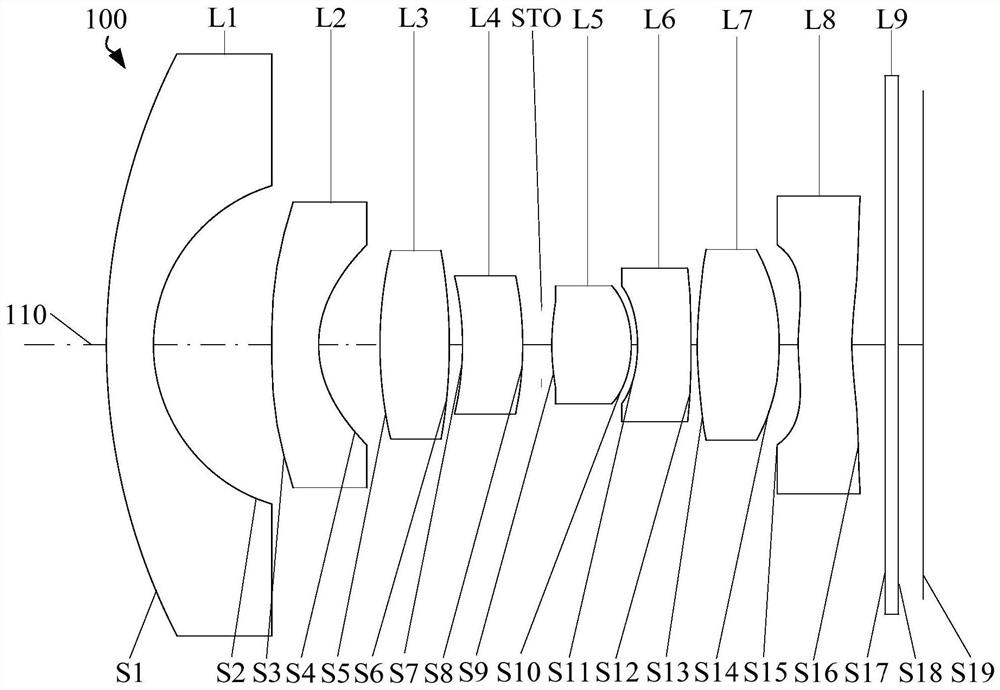

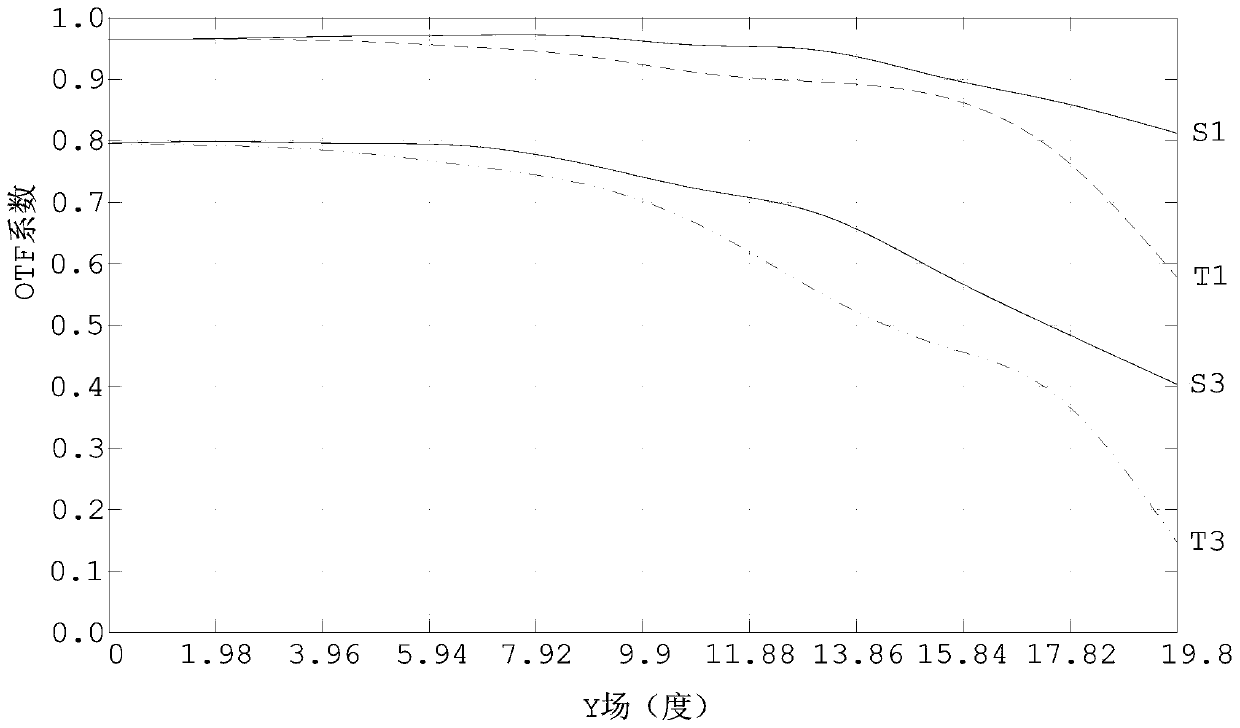

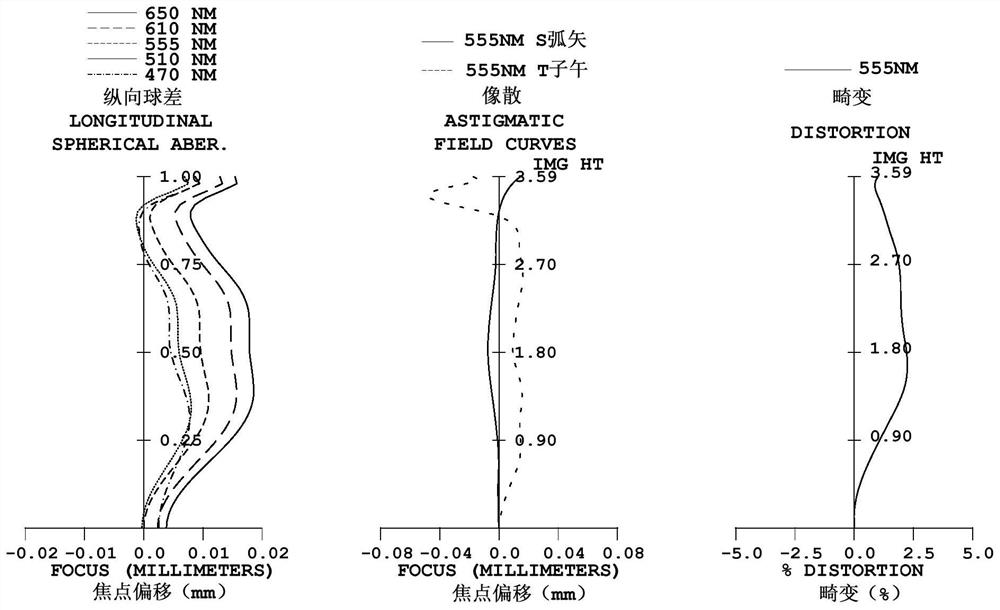

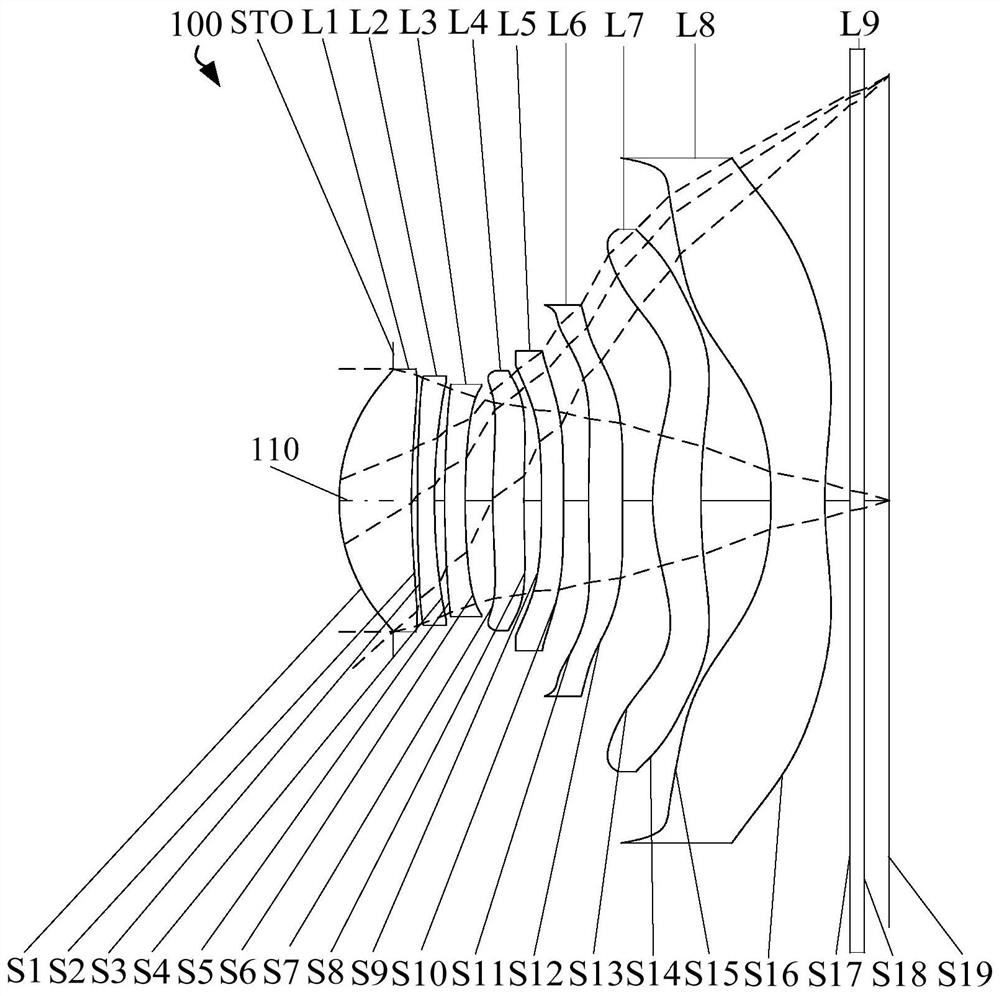

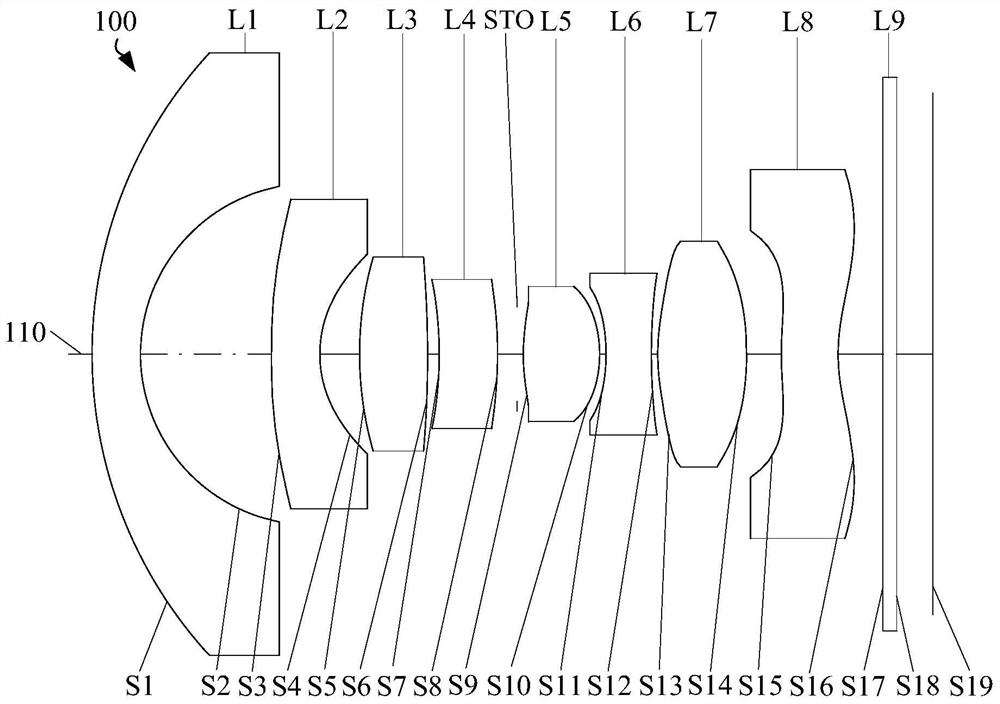

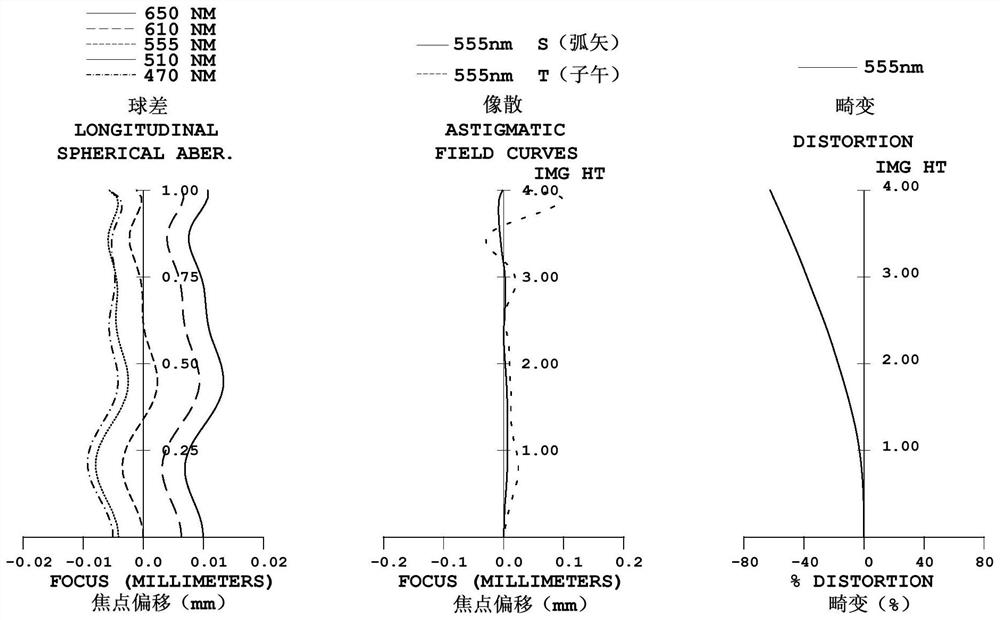

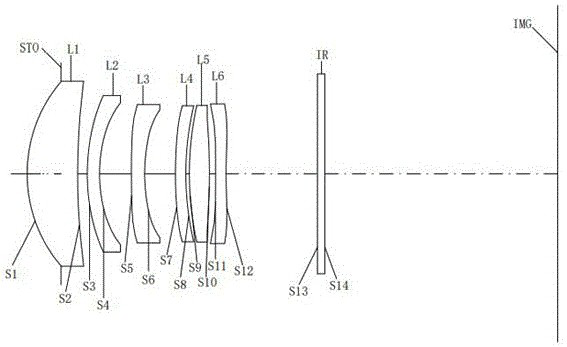

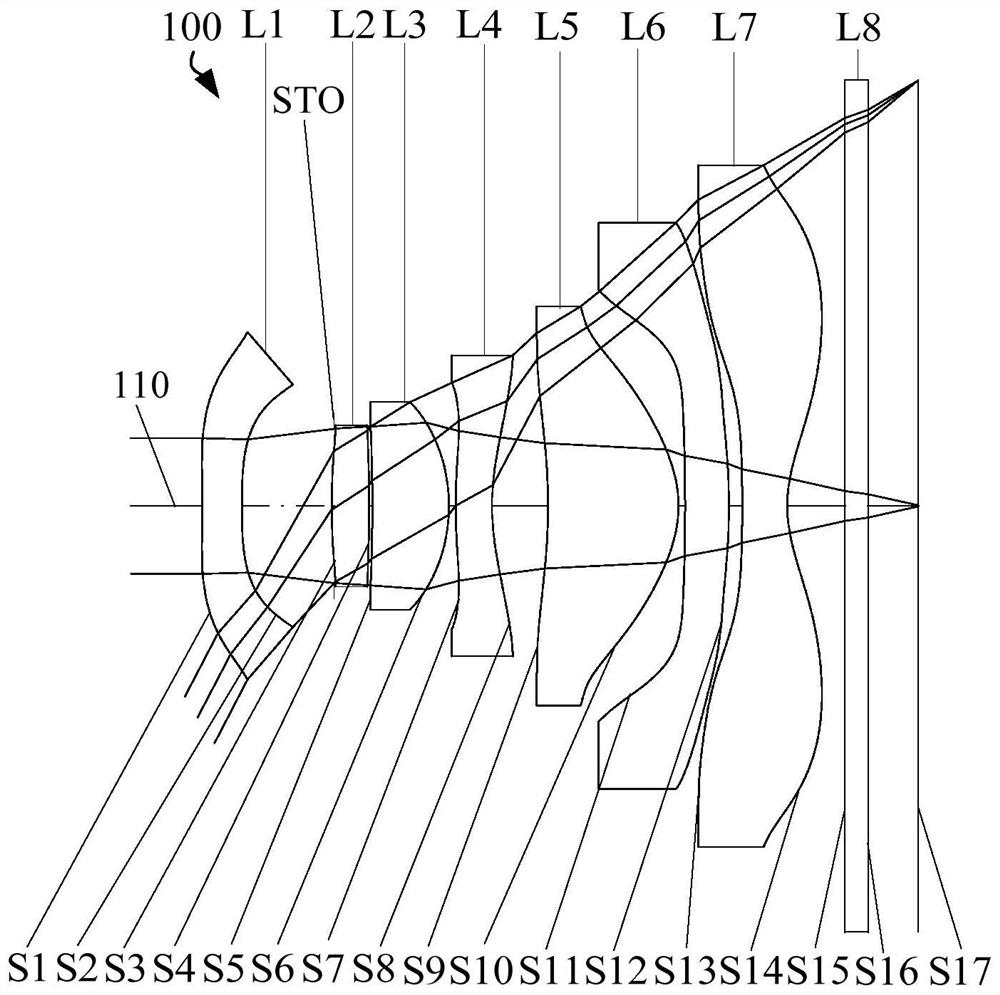

Optical system, image capturing module and electronic device

ActiveCN112987259AMeet the needs of miniaturization designGood for wide-angle characteristicsTelevision system detailsColor television detailsOptical axisMiniaturization

The invention relates to an optical system, an image capturing module and an electronic device. The optical system includes a first lens element with negative refractive power and an object-side surface being convex in a paraxial region and an image-side surface being concave in a paraxial region; a second lens element with negative refractive power and an object-side surface being convex in a paraxial region and an image-side surface being concave in a paraxial region; a third lens element with positive refractive power and an object-side surface being convex in a paraxial region thereof and an image-side surface being convex in a paraxial region thereof; a fourth lens element with refractive power and an image-side surface being convex in a paraxial region thereof. a fifth lens element with refractive power; a sixth lens element with refractive power; a seventh lens element with positive refractive power and an image-side surface being convex in a paraxial region thereof; and an eighth lens element with refractive power and an object-side surface being convex in a paraxial region and an image-side surface being concave in a paraxial region. The conditions that TTL / (ImgH * 2) is greater than or equal to 1.5 and less than or equal to 1.7, and FOV is greater than or equal to 150 degrees and less than or equal to 170 degrees are satisfied. The optical system can realize miniaturization design and wide-angle characteristics.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Optical system, receiving module and electronic equipment

InactiveCN111596438AMeet the needs of miniaturization designSmall sizeUsing optical meansCamera filtersMiniaturizationEngineering

The invention relates to an optical system, a receiving module and electronic equipment. The optical system includes, in order from an object side to an image side, a lens element with positive refractive power and an infrared band-pass optical filter that can filter visible light wave bands and transmit infrared wave bands, and the image side surface of the lens element is attached to the objectside surface of the infrared band-pass optical filter. Moreover, the object side surface of the lens element is the light incident surface of the optical system, the image side surface of the infraredband-pass filter is the light emergent surface of the optical system, and light enters the optical system from the object side surface of the lens element, then is emitted from the image side surfaceof the infrared band-pass filter, and is imaged on the imaging surface of the optical system. According to the optical system, only one lens element and one infrared band-pass filter are arranged, sothat the size of the optical system is small, and the requirement of miniaturization design of electronic equipment can be met when the optical system is applied to the electronic equipment.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

Optical lens, camera module and electronic equipment

ActiveCN113568142AExpand the field of viewOptical total lengthOptical elementsOptical axisCamera module

The invention discloses an optical lens, a camera module and electronic equipment. The optical lens comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens which are sequentially arranged from an object side to an image side along an optical axis. The first lens with negative refractive power has a convex object-side surface and a concave image-side surface. The second lens with positive refractive power has a convex object-side surface and a concave image-side surface. The third lens with positive refractive power has a convex object-side surface and a convex image-side surface. The fourth lens with negative refractive power has a concave object-side surface and a convex image-side surface. The fifth lens with positive refractive power has an object-side surface being convex in a paraxial region thereof. The optical lens meets the following relational expression: 45 deg < HFOV / Fno < 49 deg, HFOV is half of the maximum field angle of the optical lens, and Fno is the aperture number of the optical lens; thus, the optical lens has a large view angle and also has a large aperture number to enhance the imaging effect of the optical lens in a dark light environment.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

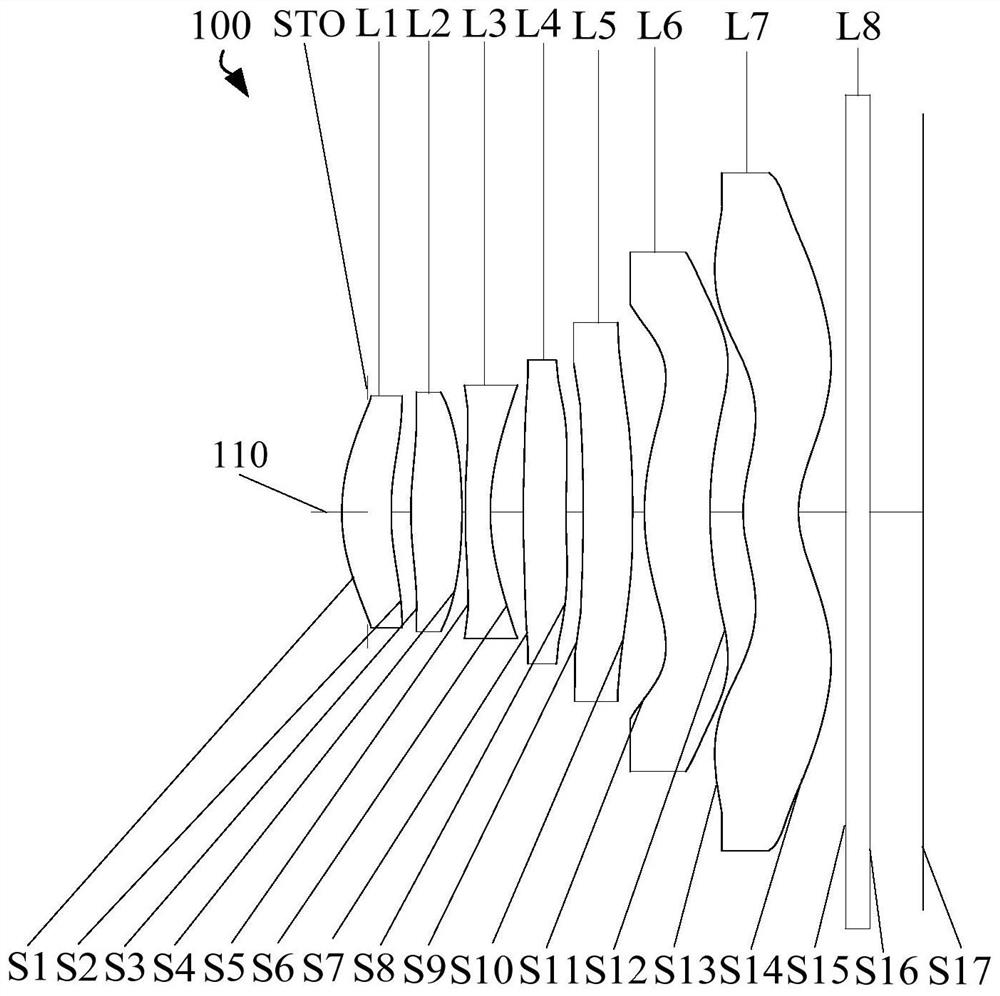

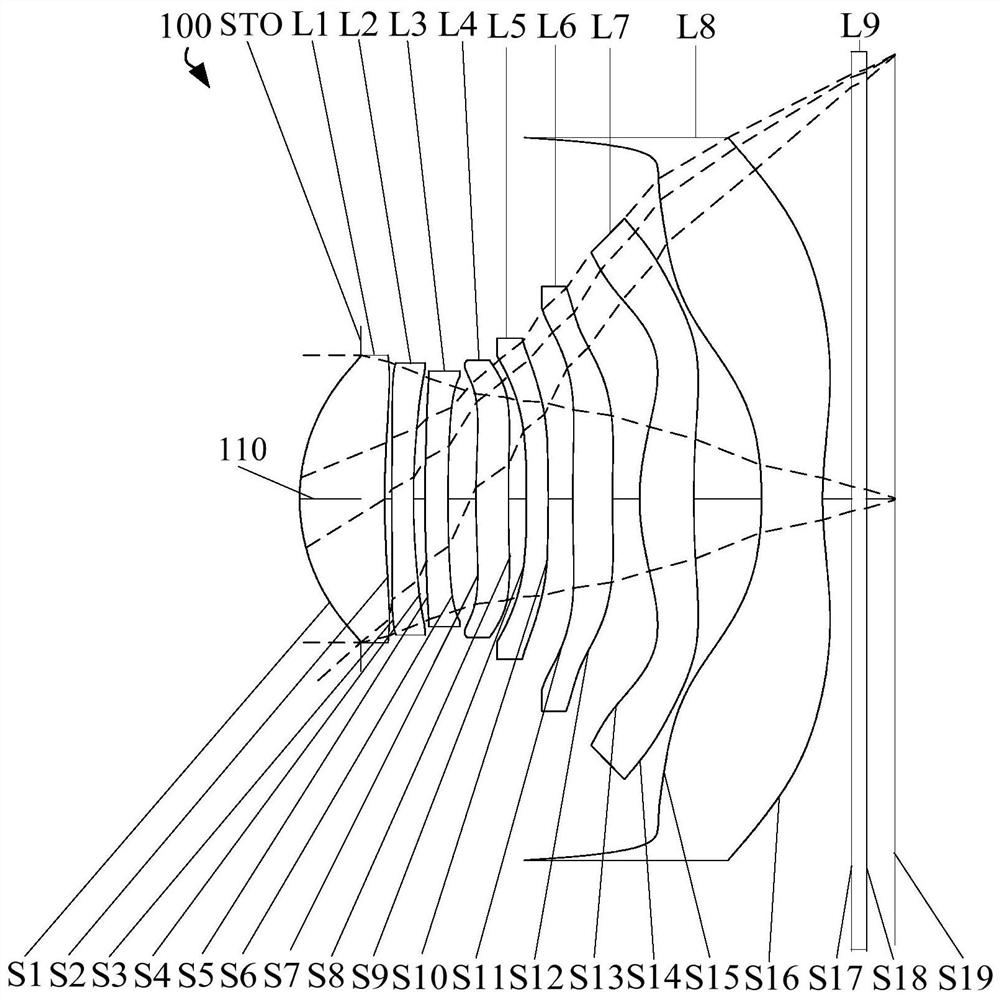

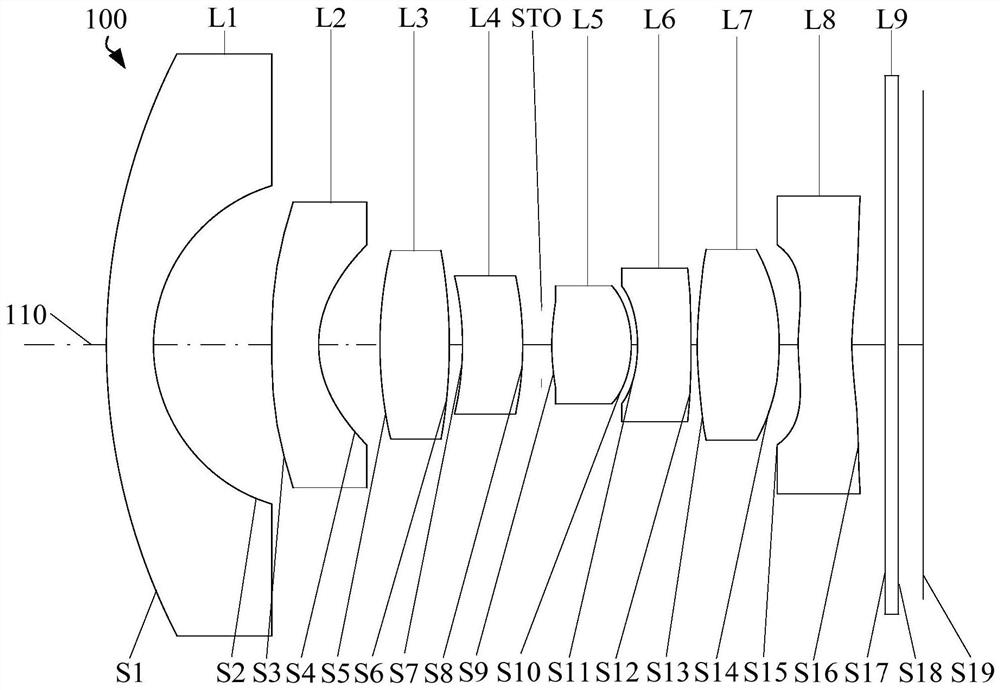

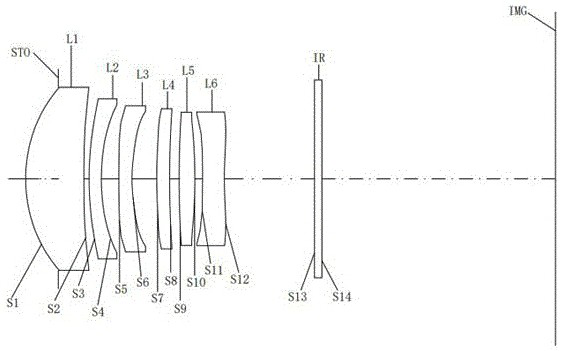

Optical system, image capturing module and electronic device

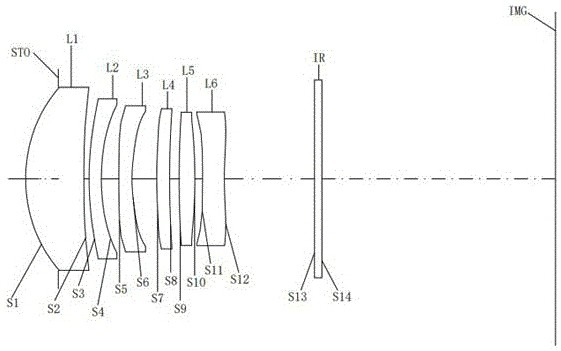

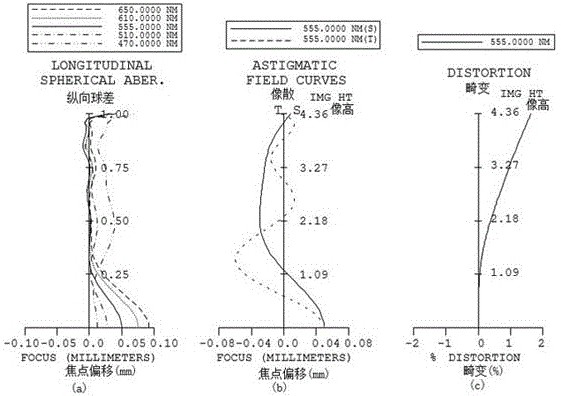

PendingCN113376810AMeet the needs of miniaturization designCompact structureOptical elementsOptical axisMiniaturization

The invention relates to an optical system, an image capturing module and an electronic device. The optical system includes, in order from an object side to an image side along an optical axis: a first lens element with positive refractive power having an object-side surface being convex in a paraxial region and an image-side surface being concave in a paraxial region; a second lens element with refractive power having an object-side surface being convex in a paraxial region thereof; a third lens element with refractive power; a fourth lens element with refractive power having an object-side surface being convex in a paraxial region and an image-side surface being concave in the optical axis; a fifth lens element with refractive power having an object-side surface being concave in a paraxial region thereof; a sixth lens element with positive refractive power having an object-side surface being convex in a paraxial region thereof; a seventh lens element with negative refractive power having an image-side surface being concave in a paraxial region thereof; |f(12) / f(67)| is less than or equal to 0.5; f(12) is the combined focal length of the first lens and the second lens, and f(67) is the combined focal length of the sixth lens and the seventh lens. The optical system can meet the requirement of miniaturization design.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

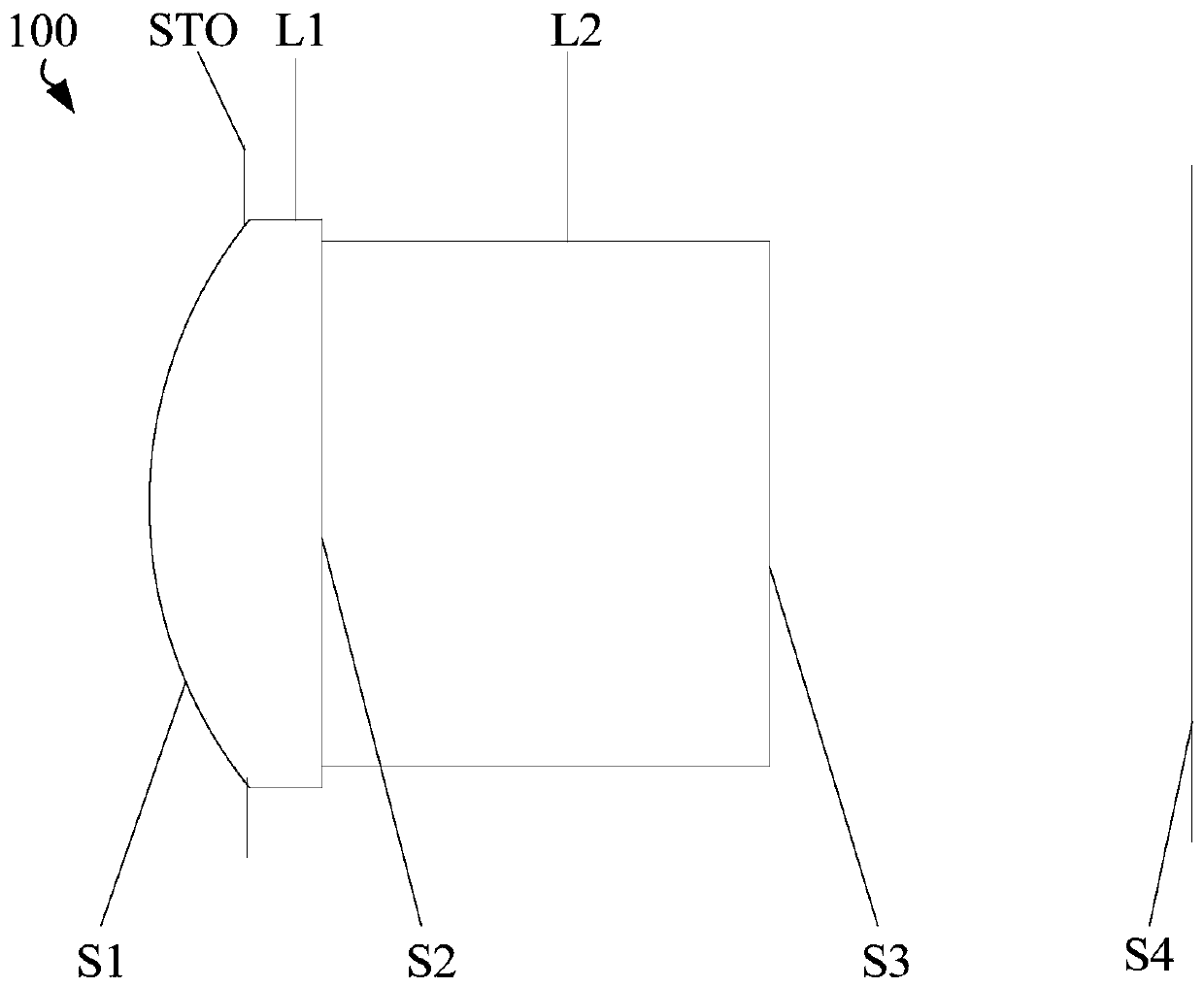

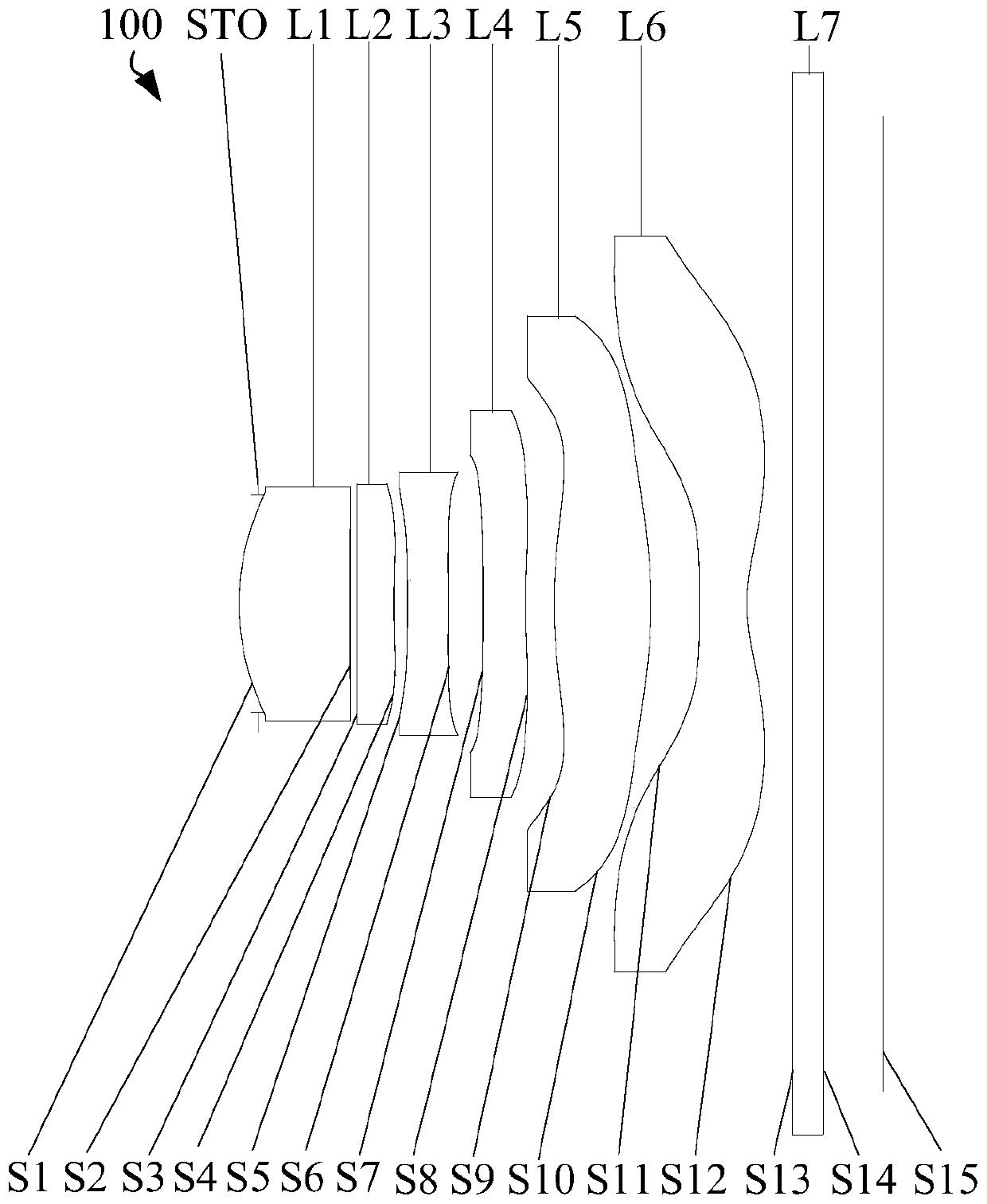

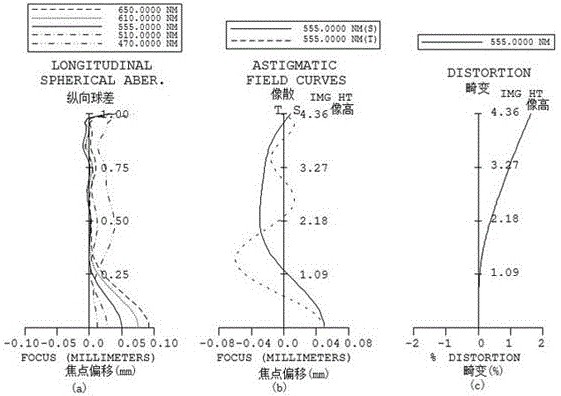

Optical system, image capturing module and electronic device

PendingCN111338057AMeet the needs of miniaturization designOptical elementsOptical axisMiniaturization

The invention relates to an optical system, an image capturing module and an electronic device. The optical system includes, in order from an object side to an image side, a first lens with positive refractive power, a second lens with refractive power, a third lens with negative refractive power, a fourth lens with negative refractive power, a fifth lens with positive refractive power, and a sixth lens with negative refractive power. The object-side surface and the image-side surface of the third lens are concave in the circumferential direction. The object-side surface and the image-side surface of the fifth lens are aspheric; and at least one of the object-side surface and the image-side surface has an inflection point. The optical system satisfies the following conditions: CT1 / SD11 islarger than 0.60 and is less than 1.01; TTL / CT1 is larger than 5.5 and is less than 9.0; the CT1 is the thickness of the first lens on the optical axis, the SD11 is half of the maximum effective aperture of the object side surface of the first lens, and the TTL is the distance from the object side surface of the first lens to the imaging surface of the optical system. According to the optical system, the head of the pick-up lens can be smaller, and the requirement of miniaturization design of electronic equipment is met.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Electrode plate, atomizer and atomization device

PendingCN111838757ASmall footprintIncrease contact areaTobaccoElectrical connectionElectric current flow

The invention discloses an electrode plate, an atomizer and an atomization device. The electrode plate comprises an electrode body annularly arranged and at least one elastic connecting arm arranged in the electrode body, one end of the elastic connecting arm is connected with the electrode body, a gap is formed between the other end of the elastic connecting arm and the electrode body and the electrode body protrudes, the electrode body is used for being externally connected with a first contact piece, and the elastic connecting arm is used for making elastic electric contact with a second contact piece. According to the embodiment of the invention, on the one hand, the electrode body is connected with the first contact piece, the contact area is large, the large current can be supported,the advantage of small duty ratio is achieved; and on the other hand, the elastic connecting arm is elastically and electrically contacted with the second contact piece to avoid metal hard connection, so that the reliability of electrical connection can be improved.

Owner:SHENZHEN GEEKVAPE TECH CO LTD

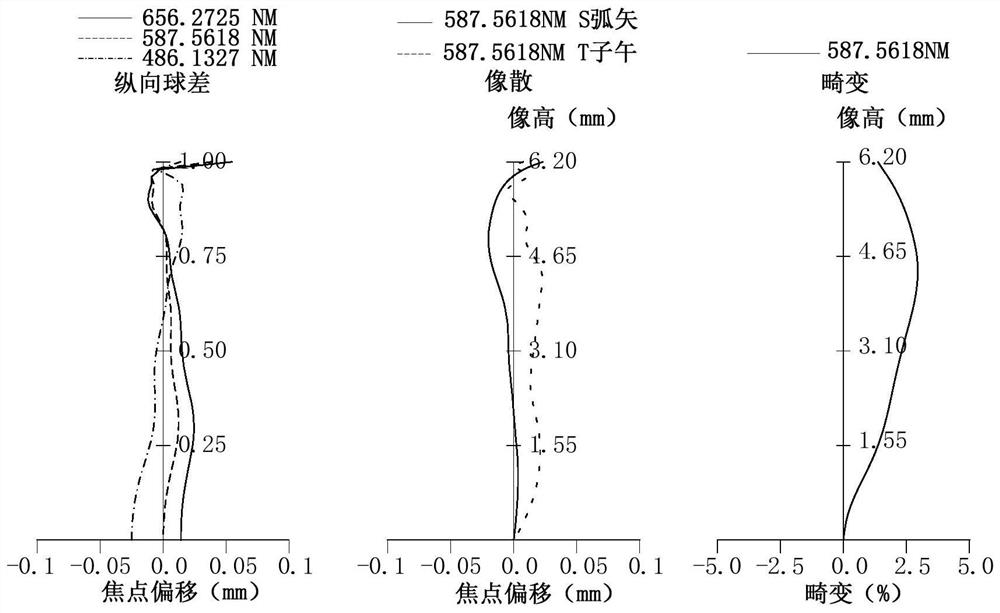

Optical system, image capturing module and electronic device

PendingCN113900226AGood aberration correction capabilityImprove image qualityOptical elementsImaging qualityOptical axis

The invention relates to an optical system, an image capturing module and an electronic device. The optical system includes a first lens element with positive refractive power, a second lens element with negative refractive power, a third lens element with refractive power having an object-side surface being convex in a paraxial region and an image-side surface being concave in a paraxial region, a fourth lens element with positive refractive power, a fifth lens element with negative refractive power, a sixth lens element with refractive power having an object-side surface being convex in a paraxial region and being concave in a circumferential region, a seventh lens element with positive refractive power having an image-side surface being concave in a paraxial region, and an eighth lens element with negative refractive power. The optical system satisfies 1< / =R14 / f7< / =6. The optical system is good in aberration correction capability and good in imaging quality.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

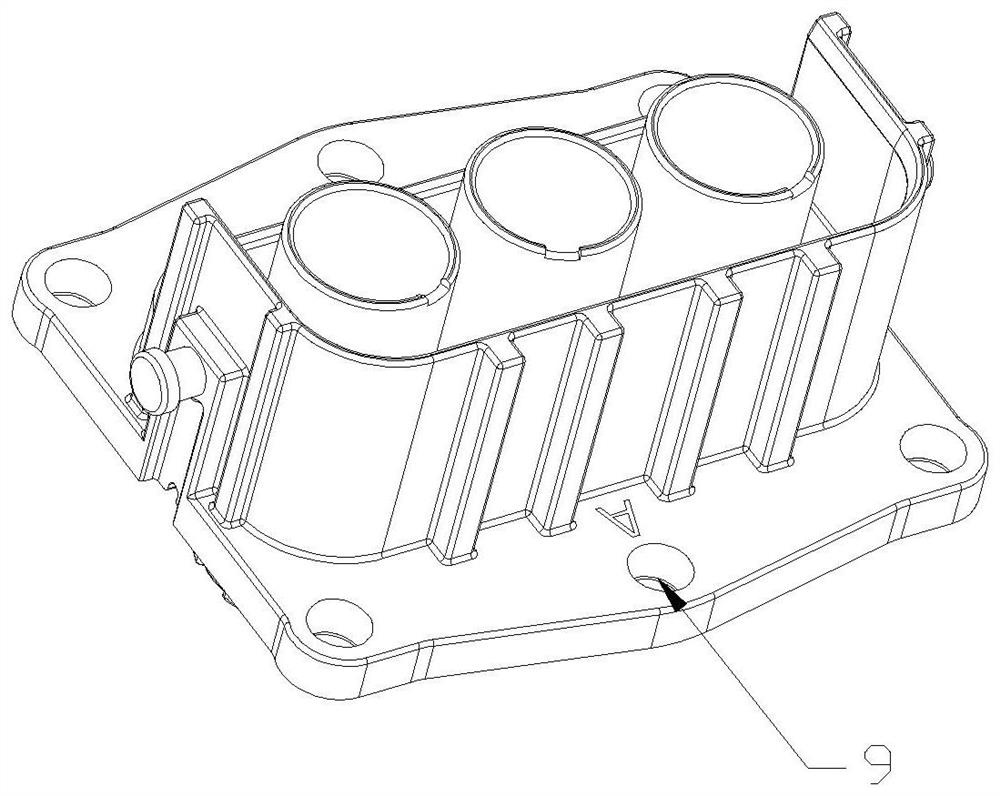

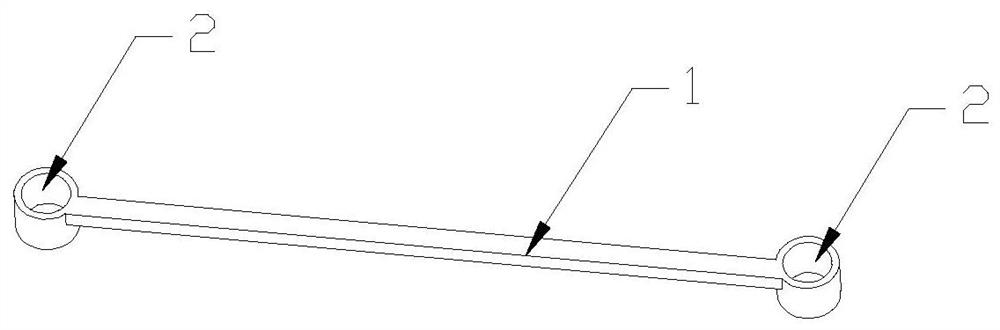

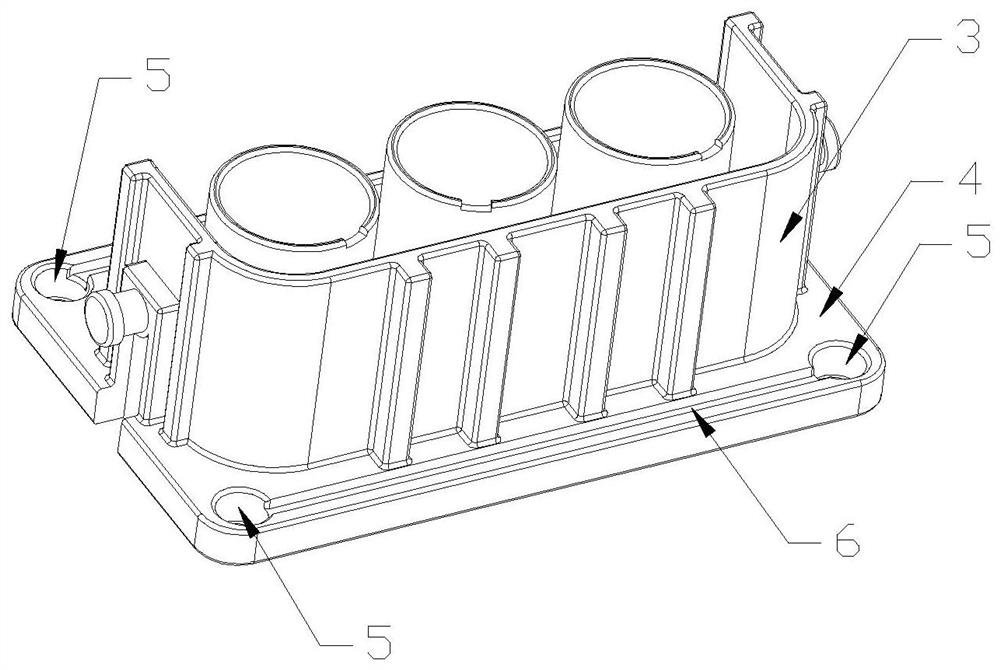

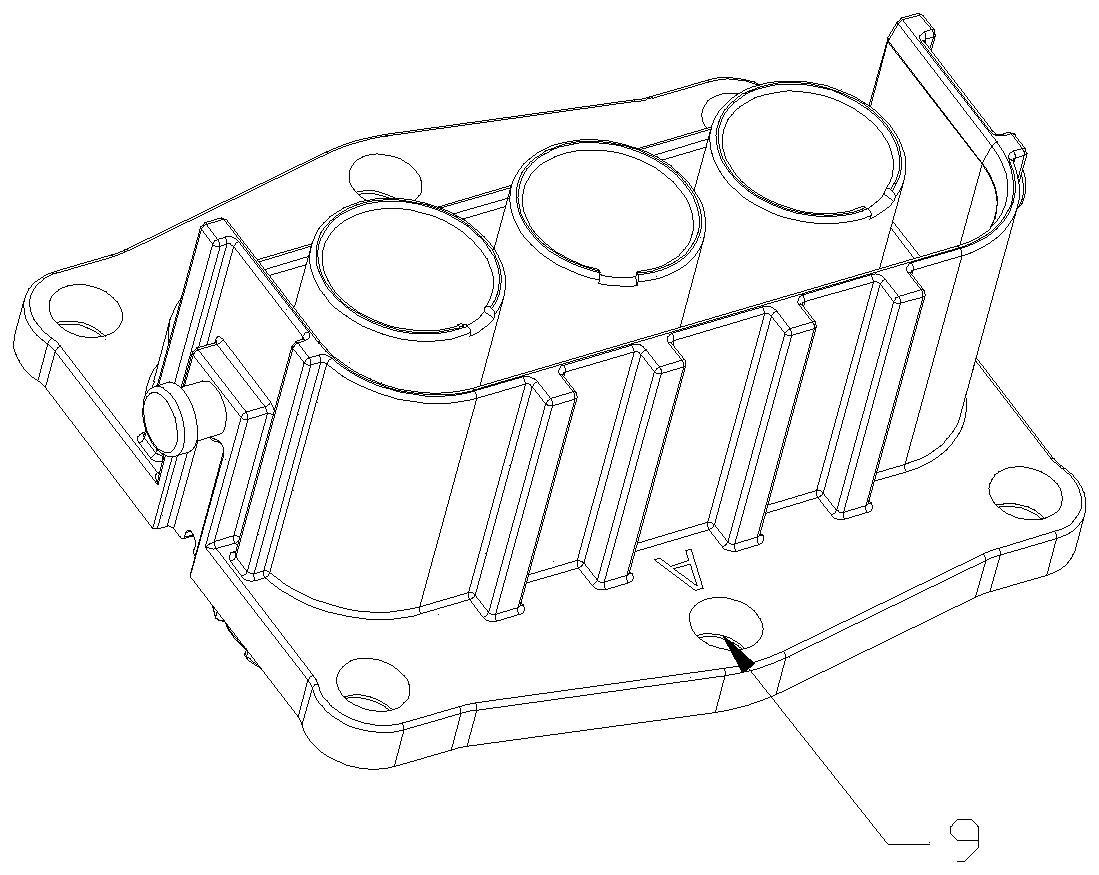

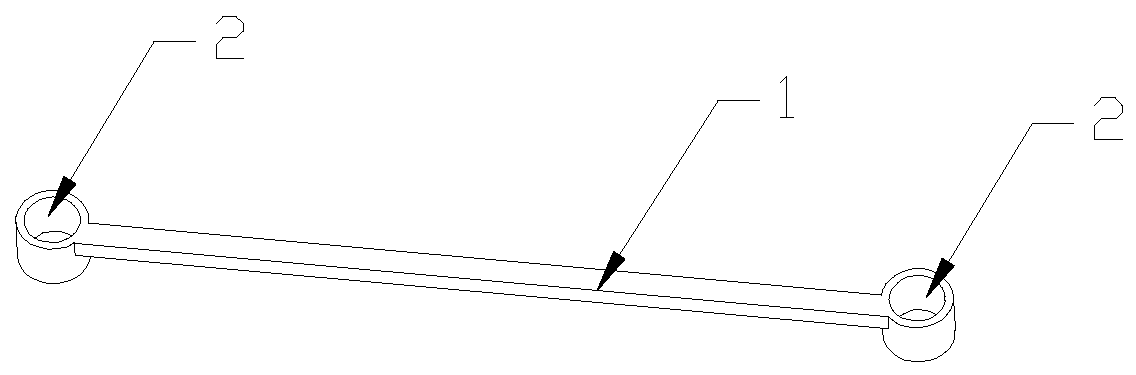

An anti-warping structure for injection molded parts

ActiveCN111048940BSolve the problem of prone to warpingReduce volumeCoupling device detailsStampingDevice Panel

The invention relates to an anti-warping structure for injection molded parts, which includes a cross bar and through holes I arranged at both ends of the cross bar. The through hole I and the cross bar are integrated. The anti-warping structure is made of stainless steel. It is stamped and formed, and its surface is also provided with a coating layer to prevent the anti-warping structure from being exposed to the air for a long time or the base material from being corroded during use. The panel of the injection molded part is provided with a groove adapted to the anti-warping structure for installing the anti-warping structure. After the injection molded part is assembled with the anti-warping structure, it is fixed to the equipment panel by bolts. The invention can effectively prevent the edge of the injection molded part from warping, even if it is exposed to the air for a long time or used at a high temperature, no warping will occur. At the same time, the invention can reduce the number of screws used, so there is no need to open multiple threaded holes on the edge of the injection molded part, which can reduce the size of the panel of the injection molded part and the volume of the injection molded part, which is beneficial to the overall reduction of the connector volume and the assembly space.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

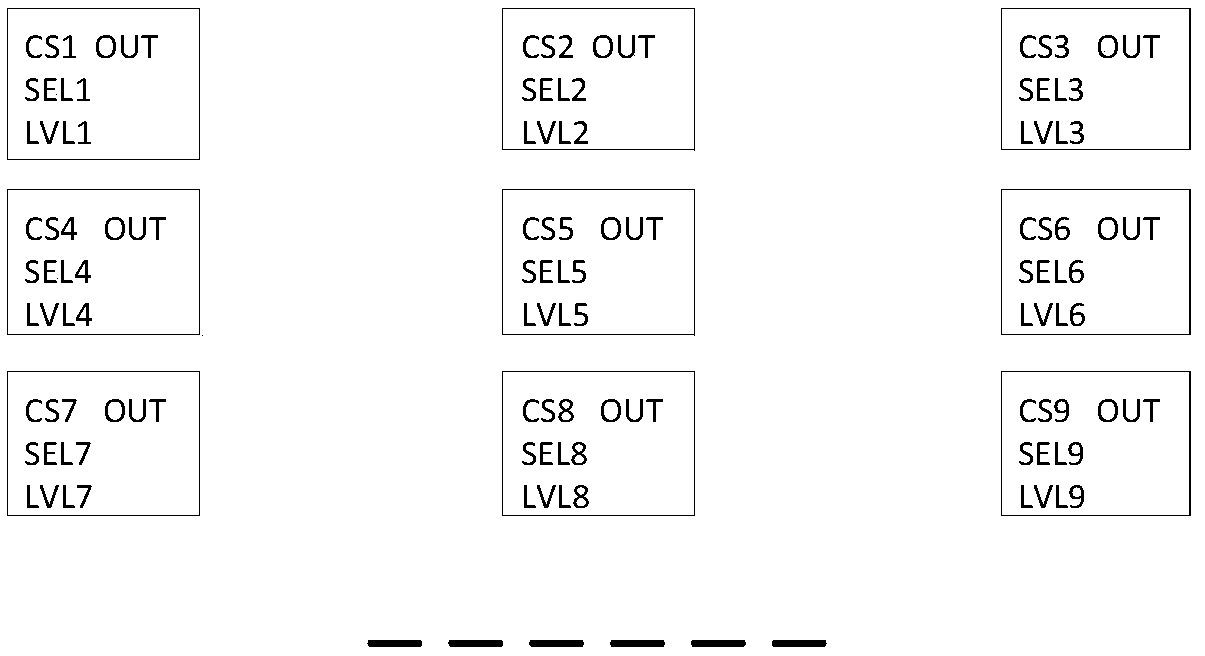

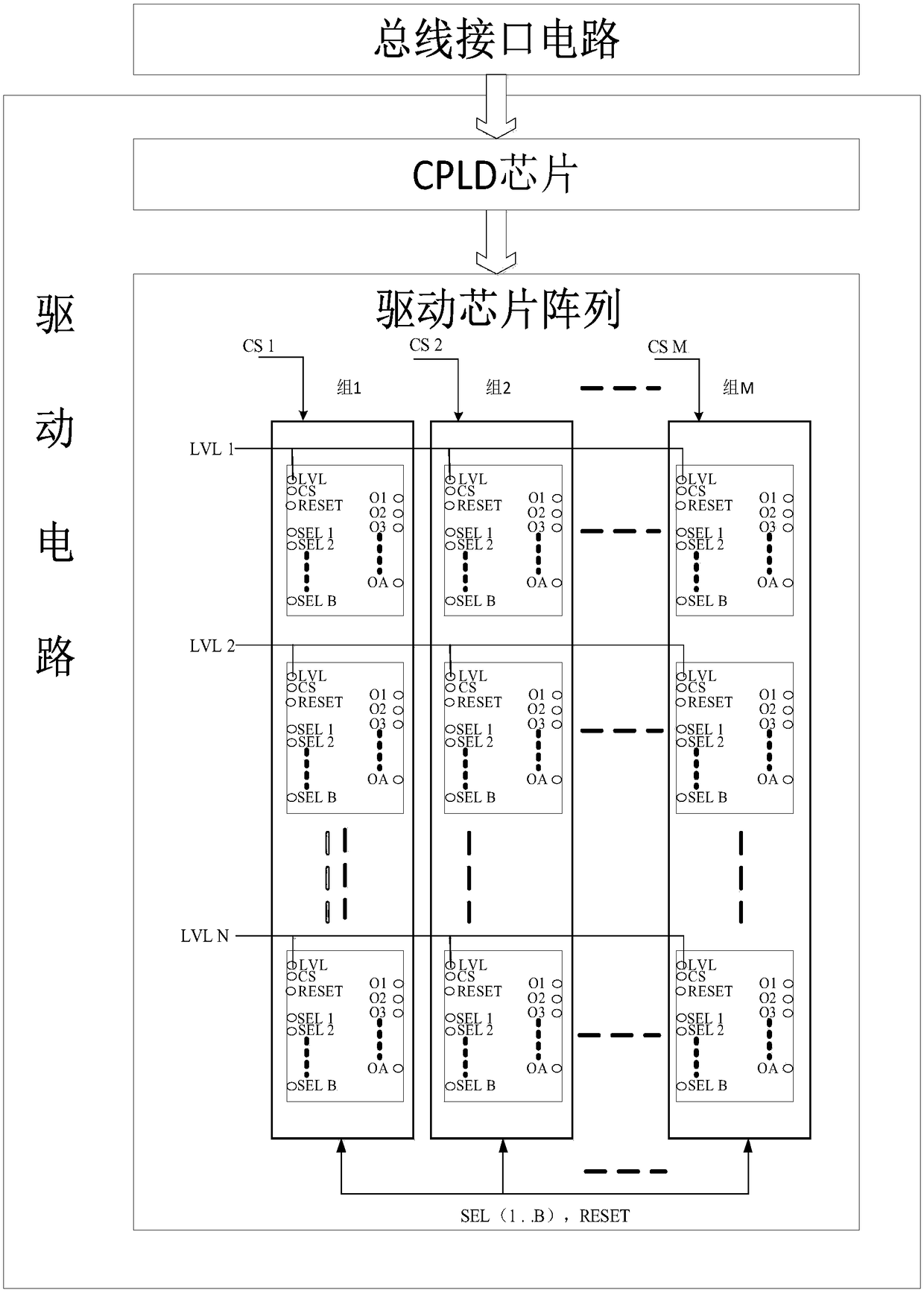

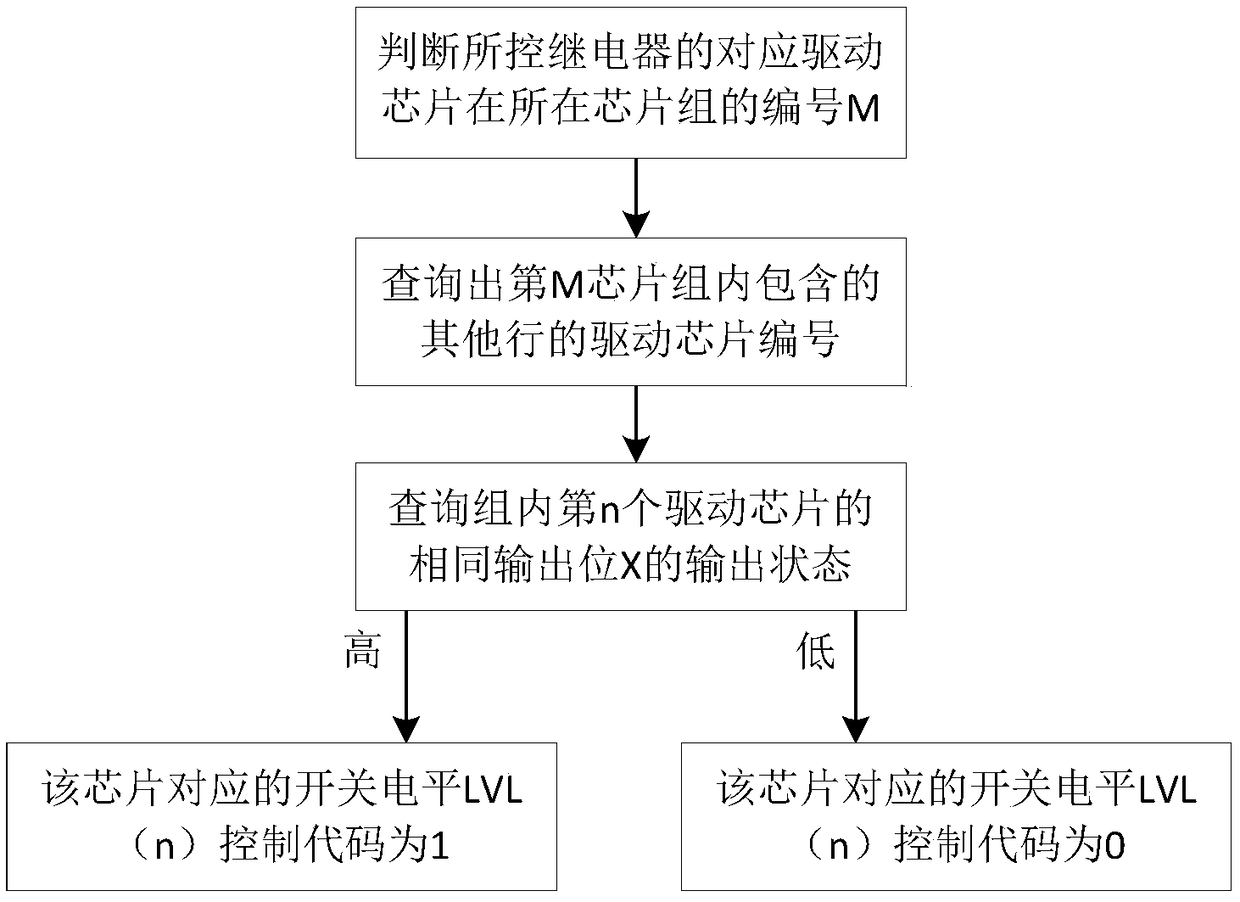

A switch matrix driving circuit and method

ActiveCN106301305BAvoid misuseMaximize efficiencyElectronic switchingAutomatic test equipmentControl signal

The invention discloses a switch matrix drive circuit and method, a CPLD chip used to receive instructions sent by a bus interface and decode the received instructions; a relay drive chip connected to the CPLD chip through a line and used to receive the CPLD The instructions decoded by the chip are selected to output valid bits through address data SEL decoding to control the corresponding relay action; wherein, the relay driver chips are M groups, any group includes N driver chips, and the driver chips of the same group share one For chip selection CS, the nth chips in different groups share a switch level signal LVL, and all drive chips share an address data SEL, where n≤N. The beneficial effects of the present invention are: by rationally designing the drive circuit and sharing the control signals in groups, the misoperation problem caused by the sharing of the control signals is effectively solved; the design integration degree of the switch matrix is improved, and the miniaturization design requirement of the automatic test equipment is met.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Anti-warping structure for injection molding piece

ActiveCN111048940ASolve the problem of prone to warpingReduce volumeCoupling device detailsDevice PanelEngineering

The invention relates to an anti-warping structure for an injection molding piece. The anti-warping structure comprises a cross rod and through holes I formed in two ends of the cross rod, the throughholes I and the cross rod are integrated, the anti-warping structure is made of stainless steel and is formed through stamping, and a coating layer is further arranged on a surface of the anti-warping structure so as to prevent the anti-warping structure from being exposed in air for a long time or prevent a base material from being corroded in a using process. A groove matched with the anti-warping structure is arranged in an injection molding piece panel and is used for installing the anti-warping structure, and the injection molding piece is fixed to an equipment panel through bolts afterthe anti-warping structure is assembled. An edge of the injection molding piece can be effectively prevented from warping, and a warping phenomenon cannot occur even if the injection molding piece isexposed in the air for a long time or used at a high temperature. Meanwhile, the number of used screws can be reduced so that multiple threaded holes do not need to be arranged in the edge of the injection molding piece, a panel size of the injection molding piece can be reduced, the size of the injection molding piece is decreased, and overall connector size reduction and assembly space reductionare facilitated.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Optical system, imaging module and electronic equipment

ActiveCN112987259BMeet the needs of miniaturization designGood for wide-angle characteristicsTelevision system detailsColor television detailsOptical axisMiniaturization

The invention relates to an optical system, an imaging module and electronic equipment. The optical system includes a first lens with negative refractive power, the object side is convex at the near optical axis, and the image side is concave at the near optical axis; the second lens with negative refractive power, the object side is convex at the near optical axis , the image side is concave at the near optical axis; the third lens with positive refractive power, the object side is convex at the near optical axis, and the image side is convex at the near optical axis; the fourth lens with refractive power, the image side Convex at the near optical axis; fifth lens with refractive power; sixth lens with refractive power; seventh lens with positive refractive power, image side convex at the near optical axis; and eighth lens with refractive power The lens, the object side is convex at the near optical axis, and the image side is concave at the near optical axis; satisfy: 1.5≤TTL / (ImgH*2)≤1.7; 150°≤FOV≤170°. The optical system enables a miniaturized design and wide-angle characteristics.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

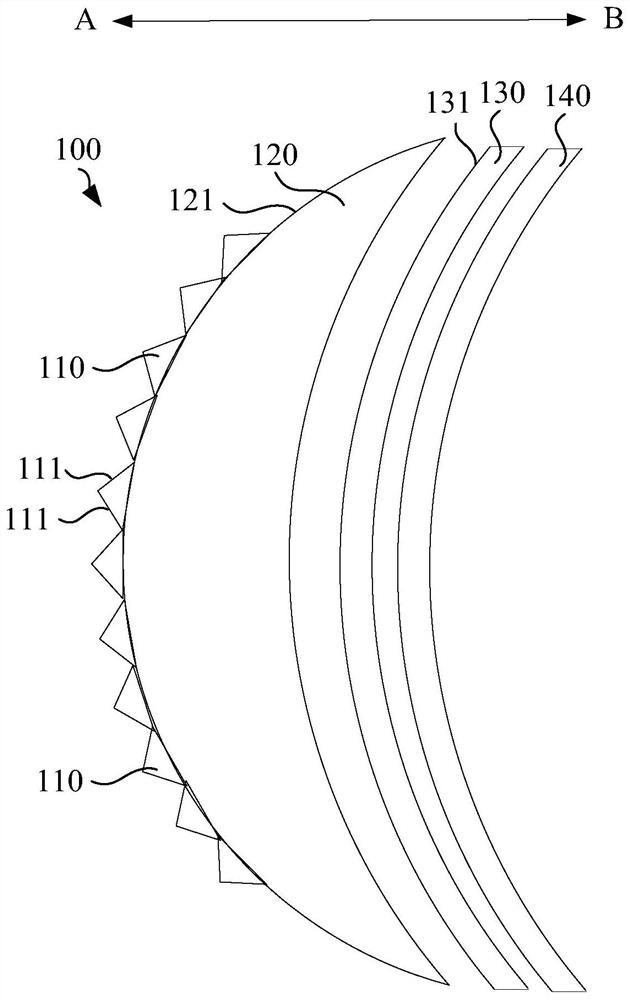

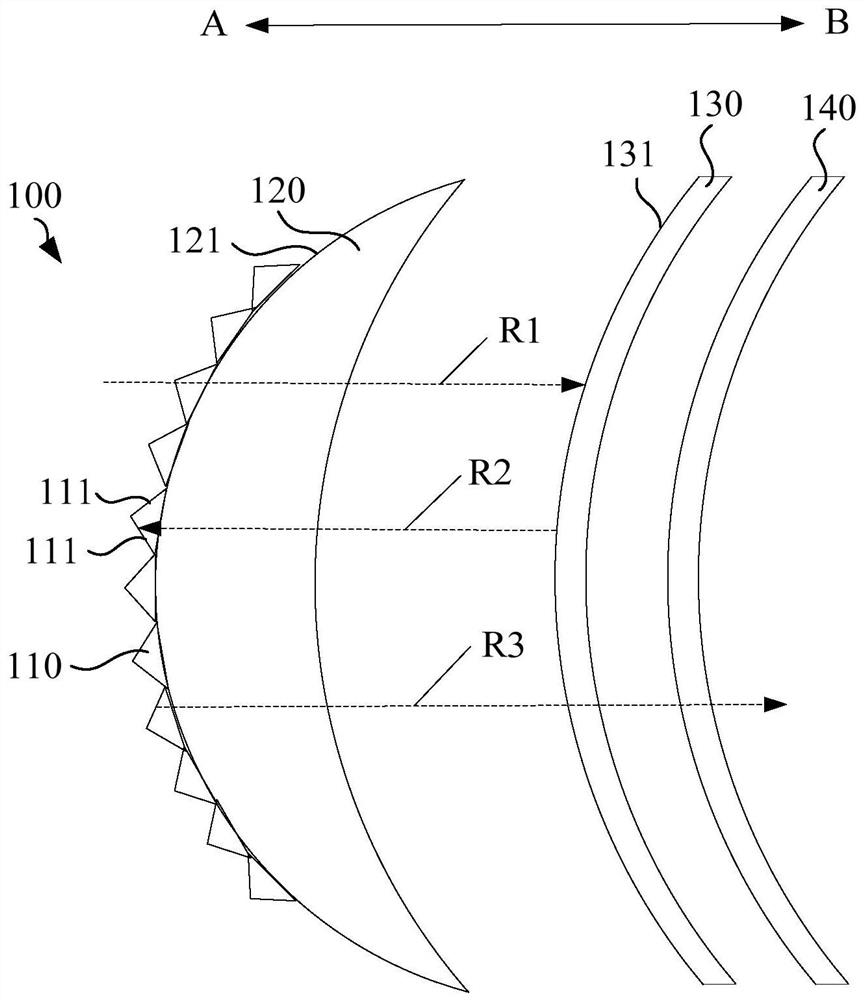

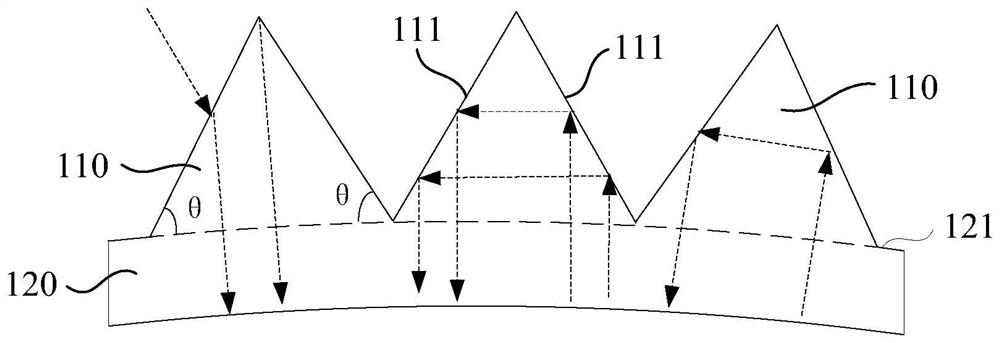

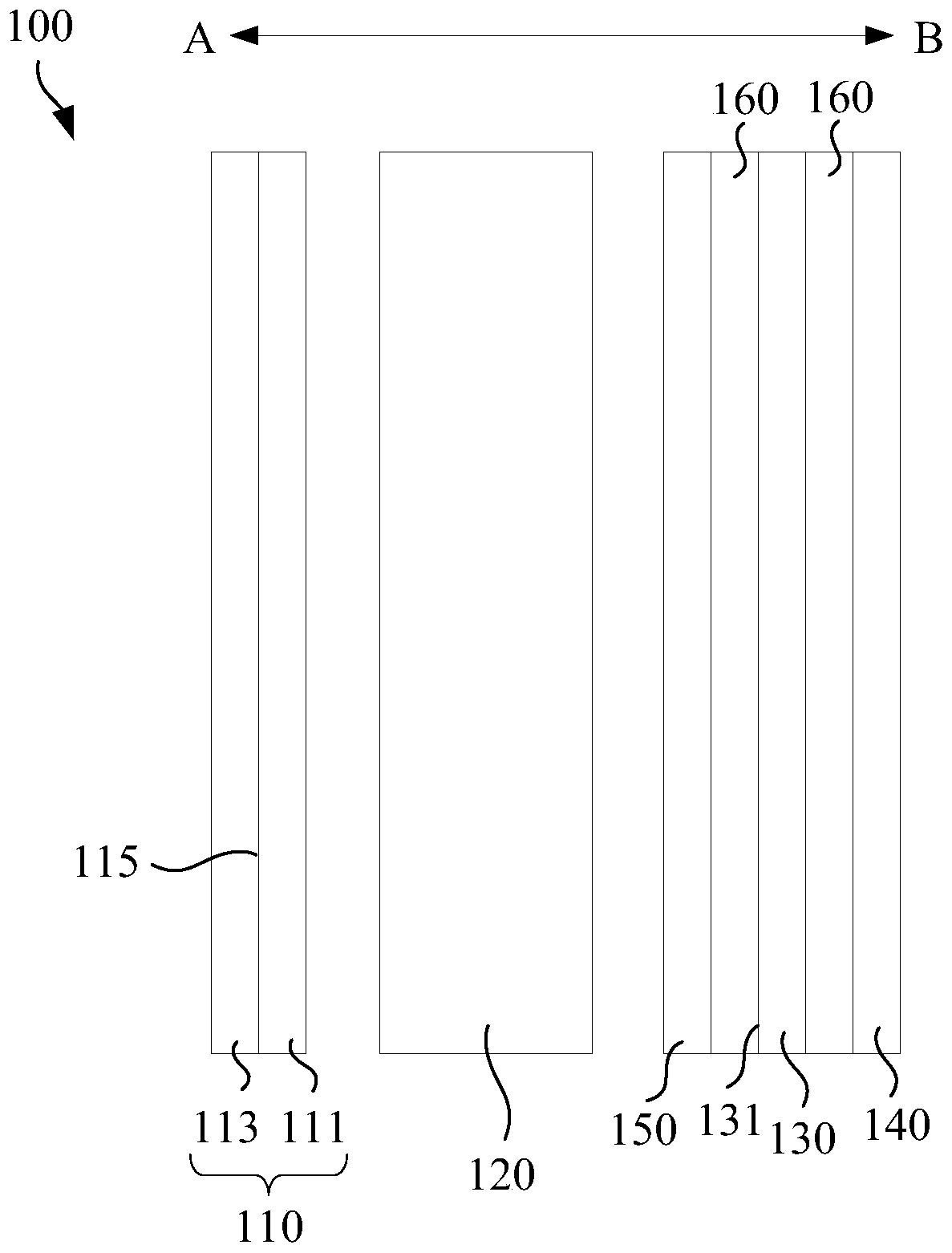

Optical imaging module and vr electronic equipment

ActiveCN110927974BSmall sizeMeet the needs of miniaturization designOptical elementsMiniaturizationEngineering

The invention relates to an optical imaging module, which sequentially includes a lens and a first polarizer from the object side to the image side. The lens has a refractive power, and a plurality of optical units are arranged on the object side of the lens, and the plurality of optical units are arranged in an array, and the optical units can transmit light from the object side and reflect light from the image side. of light. The first polarizer transmits the light polarized along the first direction, and reflects the light polarized along the second direction, the first direction is different from the second direction, and the light reflected by the first polarizer The light enters the optical unit from the image side, and exits toward the image side after being reflected at least twice in the optical unit to change the polarization state. The present invention also relates to a VR electronic device comprising the above-mentioned optical imaging module. The above-mentioned optical imaging module can achieve the effect of size reduction and meet the requirement of miniaturization design of VR electronic equipment.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Optical imaging module and VR electronic equipment

InactiveCN110955052ASmall sizeMeet the needs of miniaturization designOptical elementsMiniaturizationEngineering

The invention relates to an optical imaging module. The optical imaging module sequentially comprises a reflecting film, an optical element and a first polarizing film from an object side to an imageside, the reflective film is capable of transmitting light from an object side and reflecting light from an image side. The optical element includes at least one lens, and the optical element has refractive power. The first polaroid allows light polarized along a first direction to pass through and reflects light polarized along a second direction, wherein the first direction is different from thesecond direction, and the light reflected by the first polaroid reaches the reflecting film from the image side, and is emitted towards the image side after the reflecting film generates reflection of changing the polarization state at least once. The invention further relates to VR electronic equipment comprising the optical imaging module. The optical imaging module can achieve the effect of size reduction, and meets the requirements of miniaturization design of VR electronic equipment.

Owner:INTERFACE TECH CHENGDU CO LTD +2

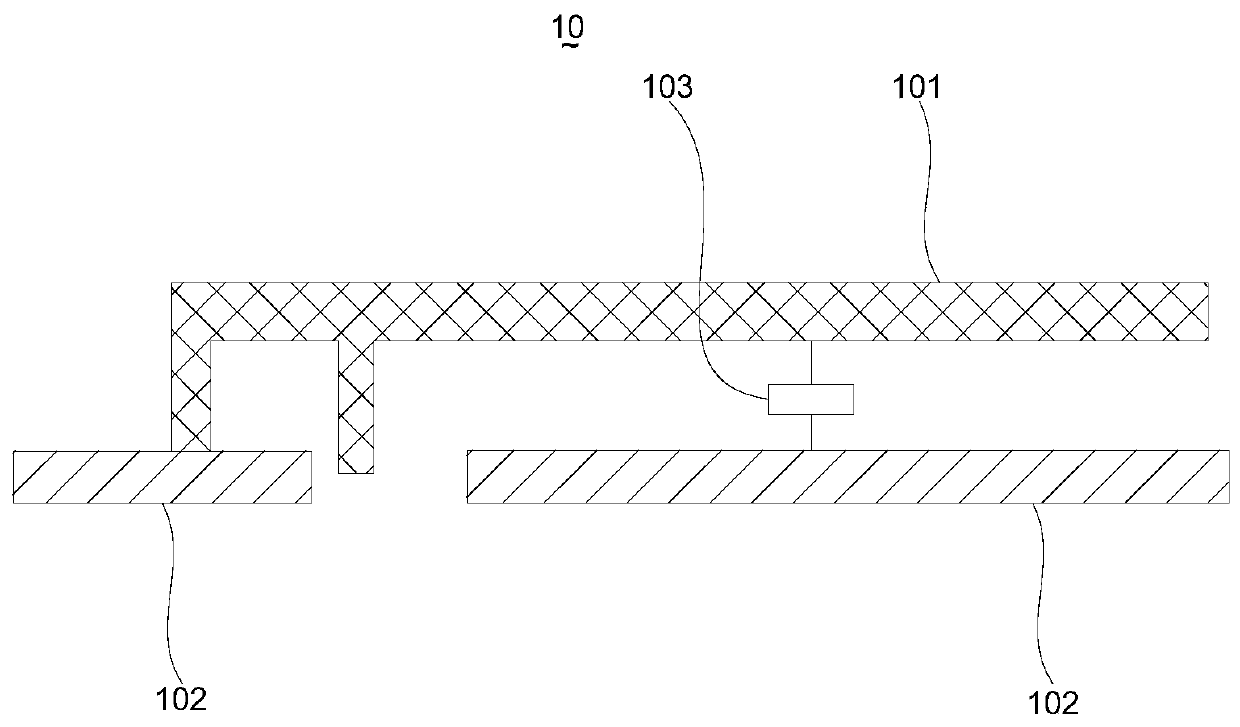

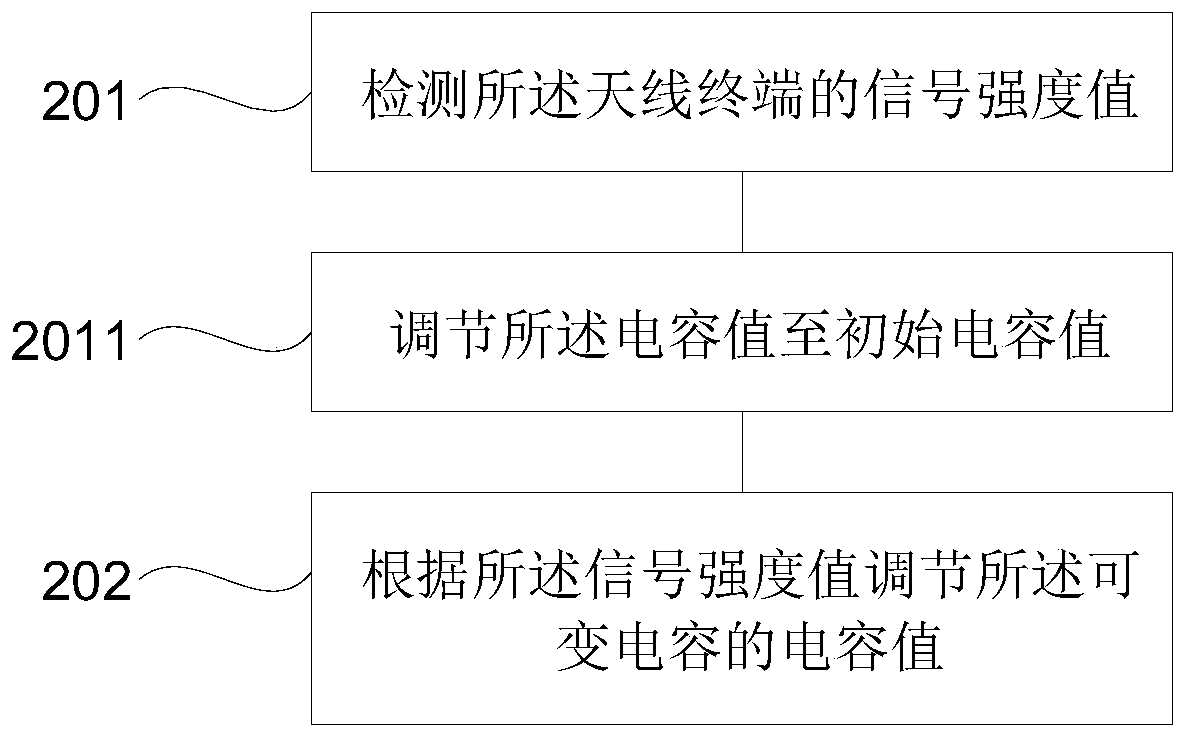

Reconfigurable antenna control method, device and mobile electronic equipment

ActiveCN107464987BSimple structureSmall sizeAntenna supports/mountingsRadiating elements structural formsCapacitanceReconfigurable antenna

The invention provides a reconfigurable antenna control method and device and mobile electronic equipment. The method comprises the steps of detecting a signal intensity value of an antenna terminal; judging whether the signal intensity value is higher than a signal intensity threshold value or not; and adjusting a capacitance value until the signal intensity value is higher than the signal intensity threshold value when the signal intensity value is lower than the signal intensity threshold value. With the reconfigurable antenna control method and device and the mobile electronic equipment, provided by the embodiment of the invention, the resonant frequency of an antenna can be automatically adjusted according to a current working effective frequency band, frequency reconfiguration of the antenna terminal is achieved, the effective bandwidth of the antenna terminal is substantially improved, the receiving capability of the antenna terminal is improved, and the communication capability of the mobile electronic equipment is improved; and meanwhile, the antenna structure is simplified, the antenna size is reduced, and the miniature design demand of the mobile electronic equipment can be satisfied.

Owner:GREE ELECTRIC APPLIANCES INC

Optical imaging module and VR electronic equipment

ActiveCN110927974ASmall sizeMeet the needs of miniaturization designOptical elementsMiniaturizationEngineering

The invention relates to an optical imaging module. The optical imaging module sequentially comprises a lens and a first polarizing film from an object side to an image side, the lens has refractive power, the object side surface of the lens is provided with a plurality of optical units, the plurality of optical units are arranged in an array, and the optical units can transmit light from the object side and reflect light from the image side. The first polaroid is used for transmitting light polarized along a first direction, and reflecting light polarized in the second direction, the first direction is different from the second direction, and the light reflected by the first polarizing film enters the optical unit from the image side and exits towards the image side after being reflectedin the optical unit for at least two times to change the polarization state. The invention further relates to VR electronic equipment comprising the optical imaging module. The optical imaging modulecan achieve the effect of size reduction, and meets the requirements of miniaturization design of VR electronic equipment.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Optical system, image capturing module and electronic device

InactiveCN114545595AAchieve telephoto characteristicsMeet the needs of miniaturization designOptical elementsOptical axisMiniaturization

The invention relates to an optical system, an image capturing module and an electronic device. The optical system includes: a catadioptric lens having positive refractive power and including a first refracting surface, a first reflecting surface, a second reflecting surface and a second refracting surface, the first refracting surface and the second refracting surface facing an object side, the first reflecting surface and the second refracting surface facing an image side, and the second refracting surface facing an image side; the first refracting surface and the second reflecting surface are concave surfaces, and the first reflecting surface and the second refracting surface are convex surfaces; a second lens element with positive refractive power having an image-side surface being convex in a paraxial region thereof; a third lens element with negative refractive power having an object-side surface being concave in a paraxial region thereof; the fourth lens element with refractive power has an object-side surface being concave in a paraxial region and an image-side surface being convex in a paraxial region. According to the optical system, the long-focus characteristic and the miniaturization design can be realized.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD

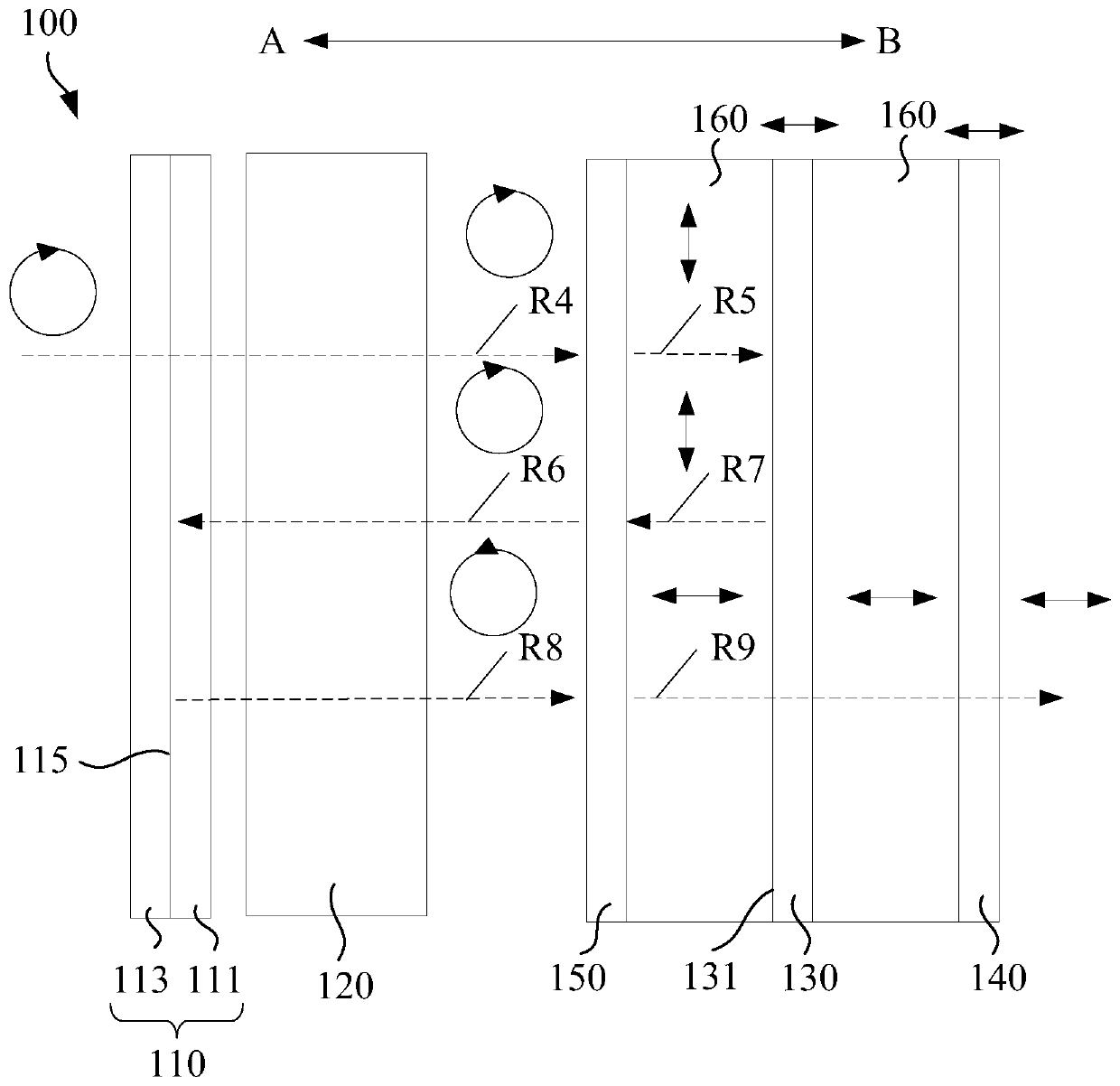

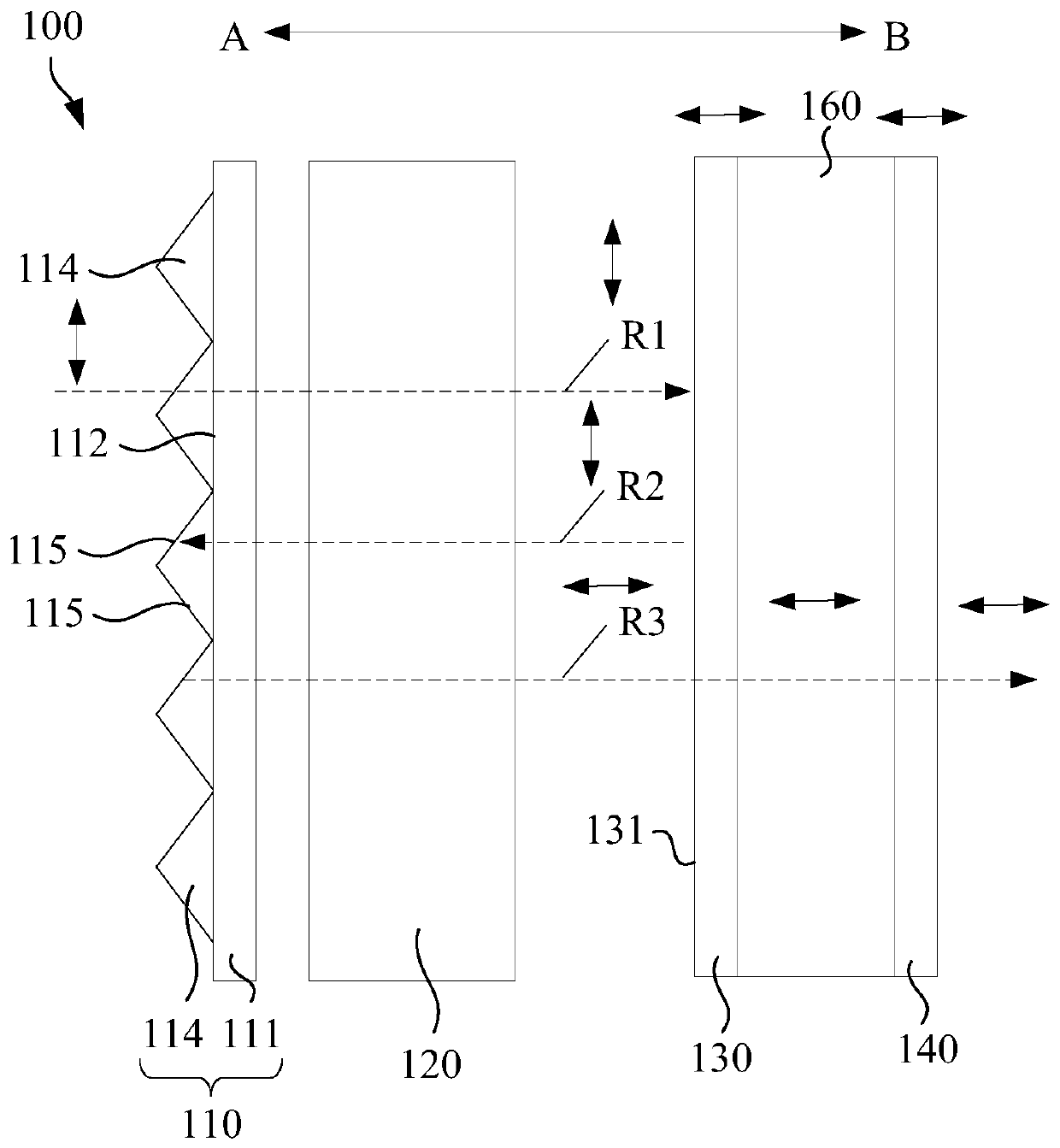

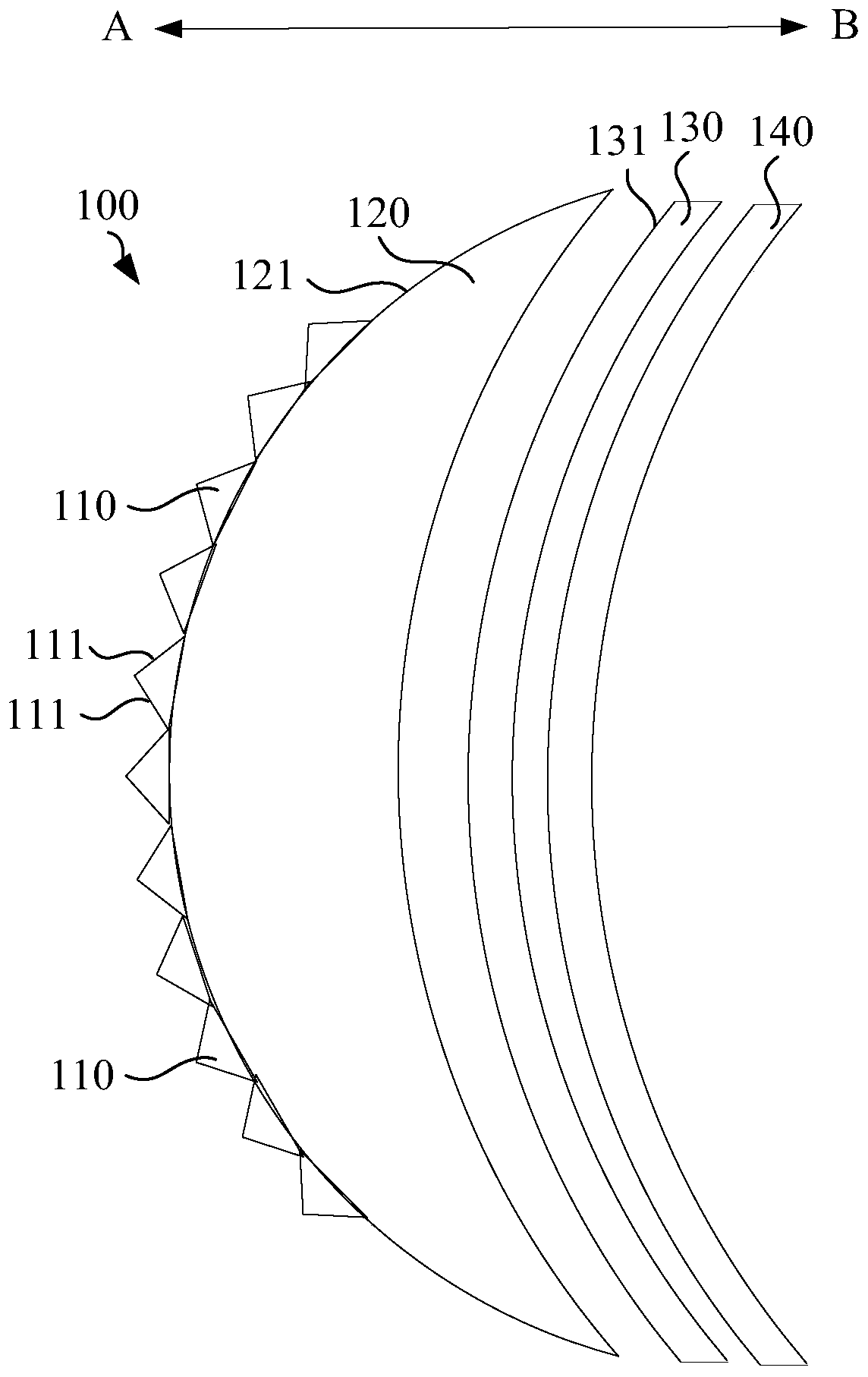

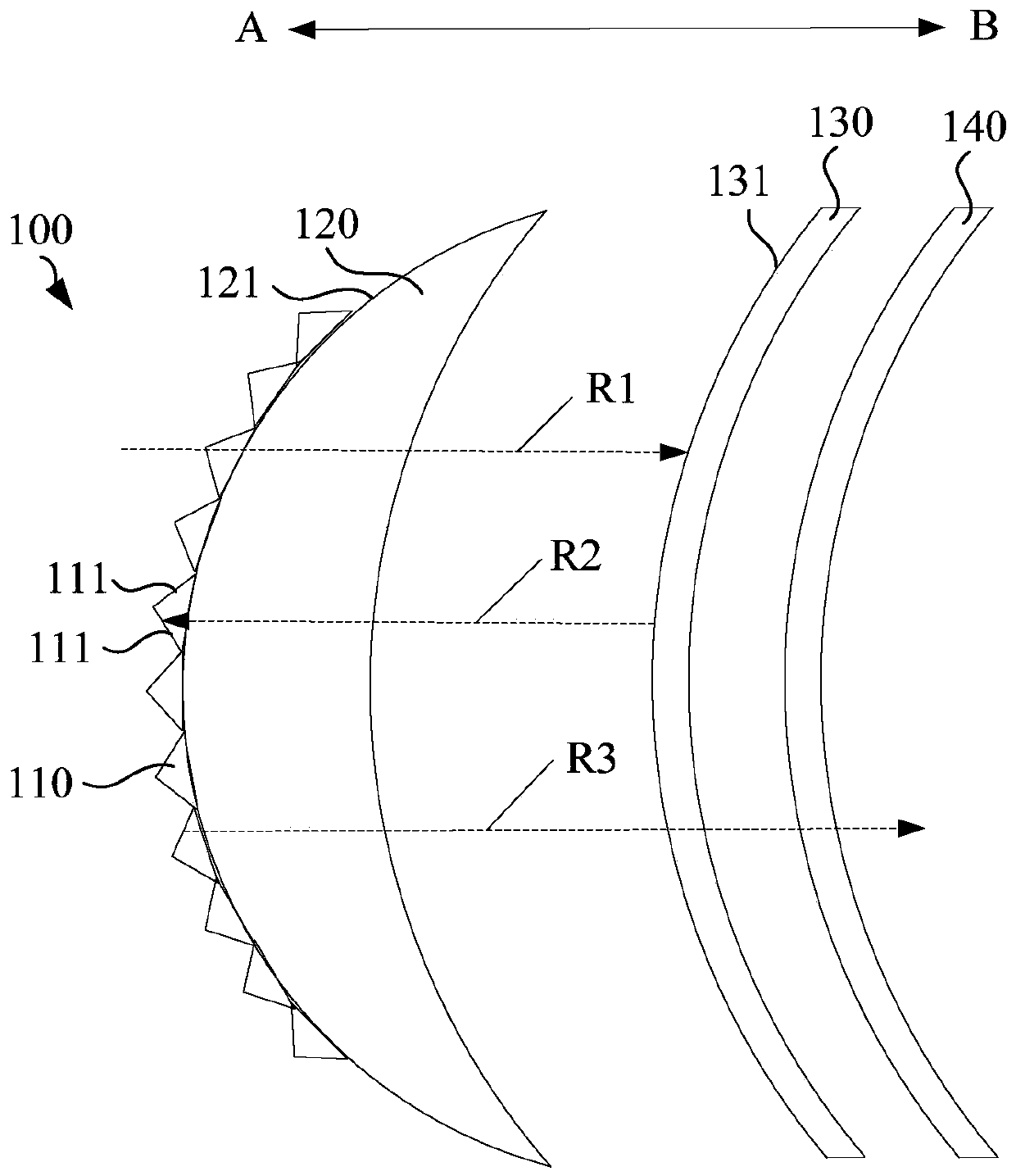

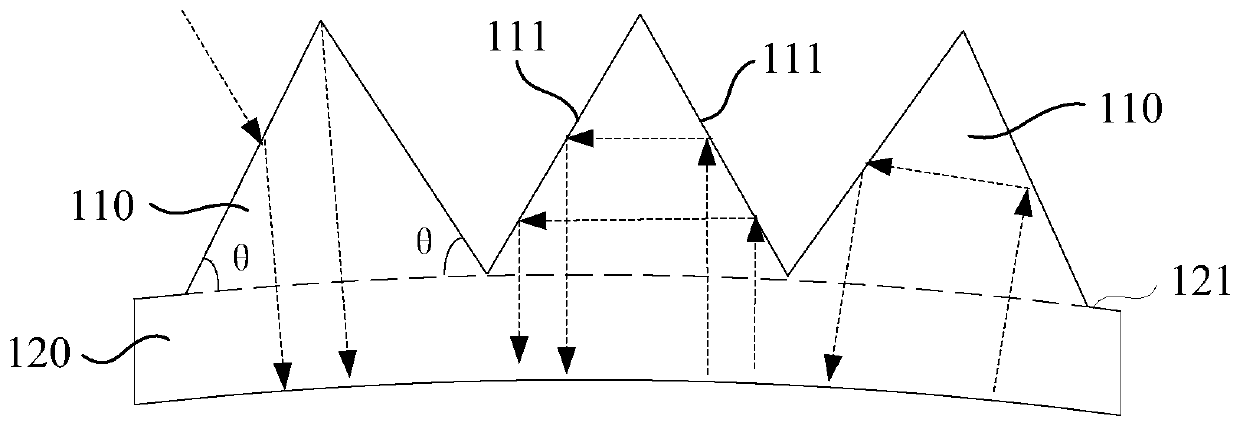

Antenna unit, mimo antenna and terminal

ActiveCN106935960BSmall sizeMiniaturizationSimultaneous aerial operationsRadiating elements structural formsTelecommunicationsMimo antenna

This patent application relates to the field of communication technology, and in particular to an antenna unit, MIMO antenna and terminal. The antenna unit can realize the miniaturization of the antenna unit while realizing the multi-band operation, and can reduce the size of the MIMO antenna when applied to the MIMO antenna, and can meet the requirements of the small size of the terminal when the MIMO antenna is applied to the terminal. design needs. An embodiment of the present patent application provides an antenna unit, the antenna unit includes: a clearance area, a support, and at least two branches; each branch is respectively arranged on the support; part of the projection of the support on the horizontal plane falls in the clearance area, and each The projection on the horizontal plane of one end of a stub used to connect the feed point is located outside the clear area, and the projection of the end on the horizontal plane is located inside the clear area.

Owner:HUAWEI TECH CO LTD

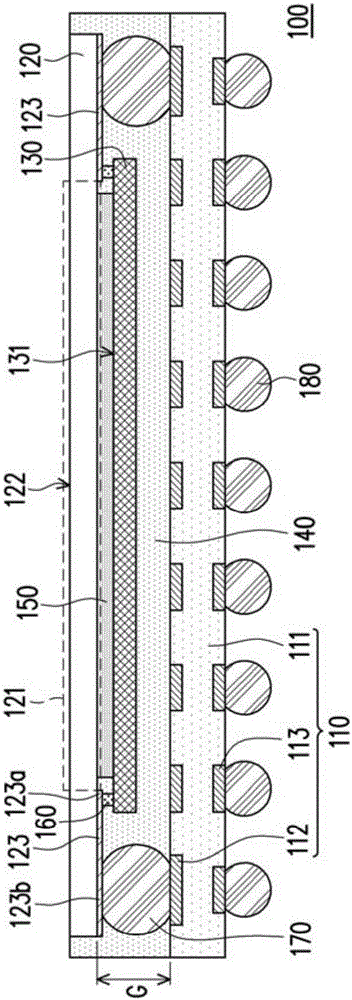

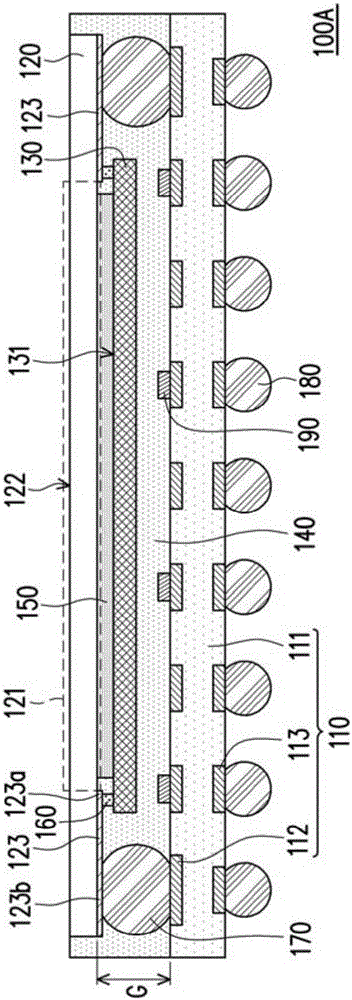

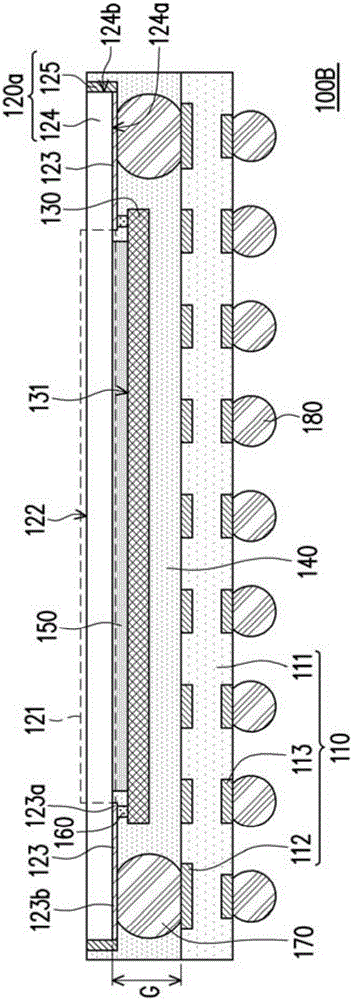

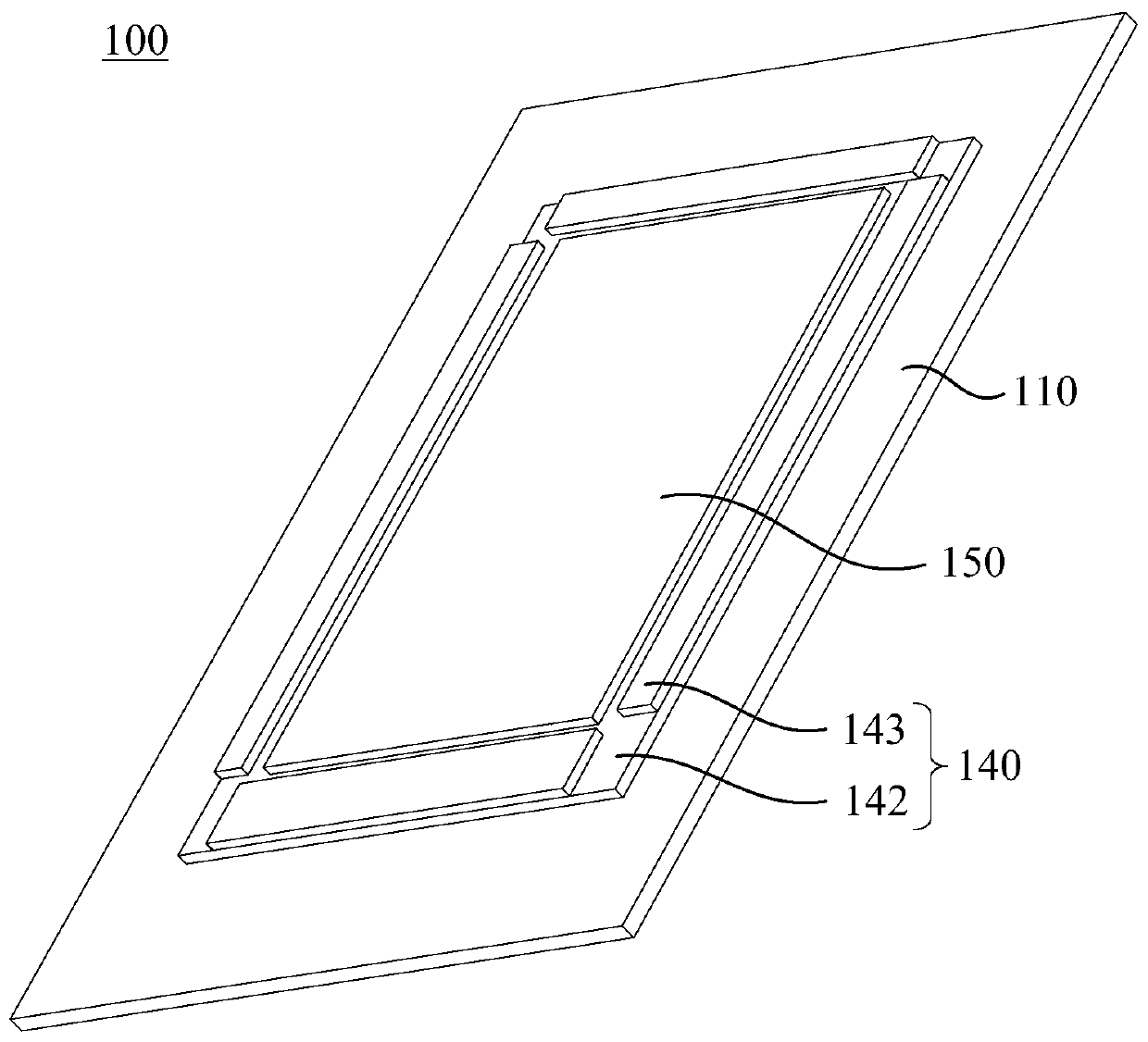

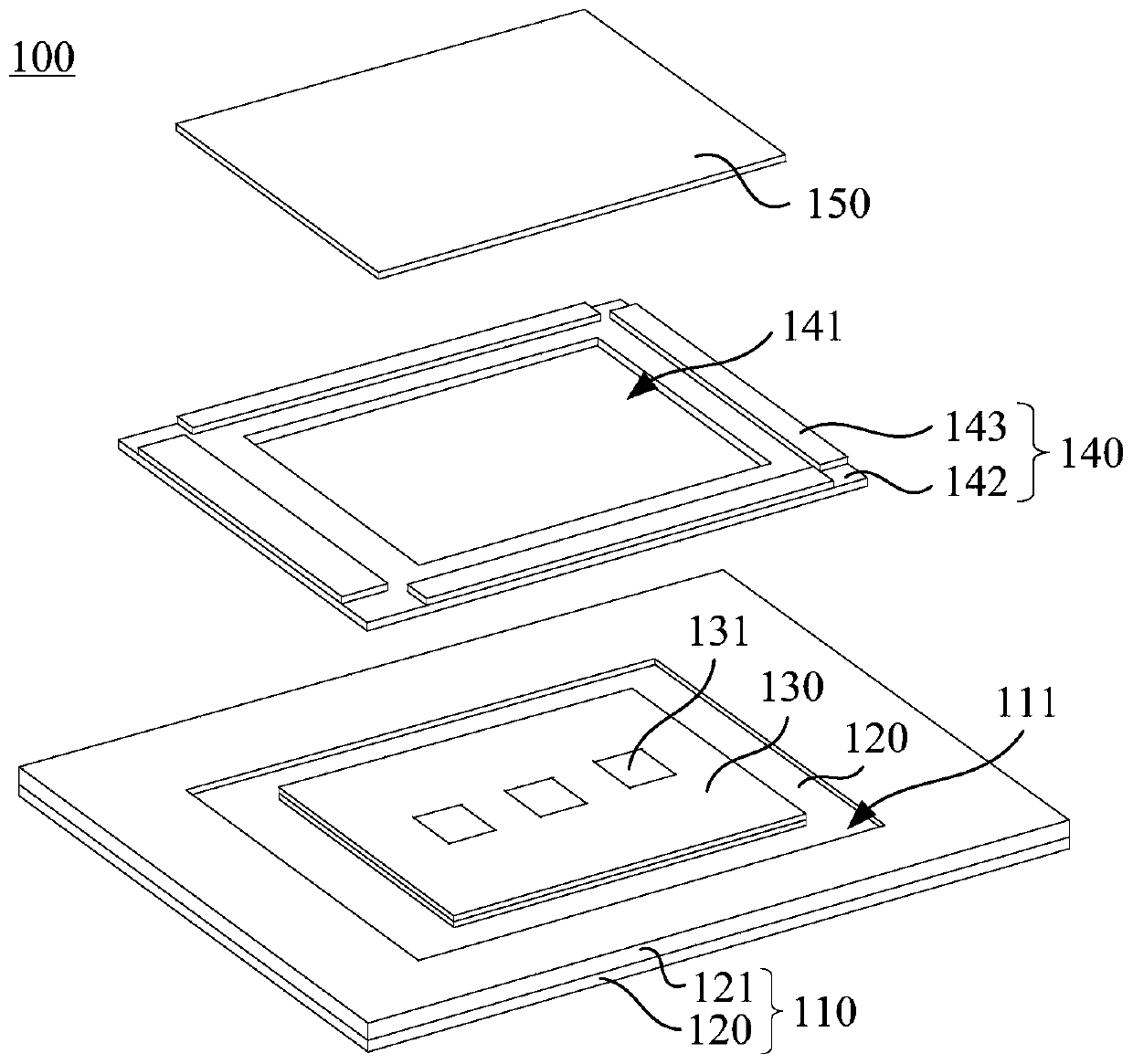

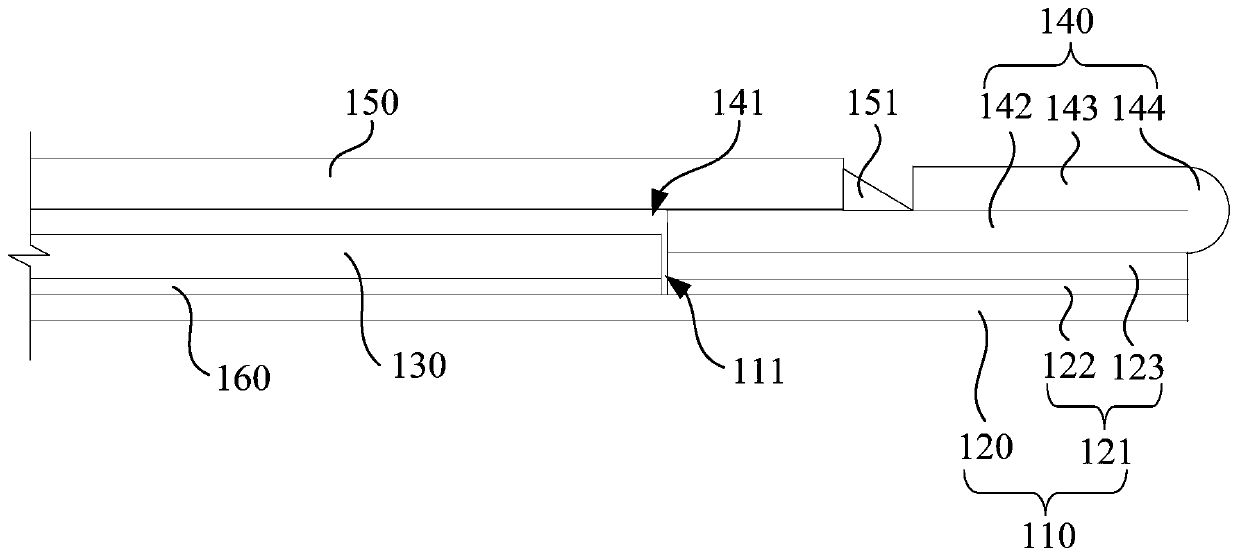

Optical fingerprint sensing packaging structure

InactiveCN107180217AReduce volumeThe overall thickness is thinPrint image acquisitionEngineeringFingerprint

The invention provides an optical fingerprint sensing packaging structure. The optical fingerprint sensing packaging structure includes a line carrier board, an optical component, a fingerprint sensing chip and packing glue. The optical component is electrically connected to the line carrier board; a gap is formed between the optical component and the line carrier board; and the optical component has a light-transmitting region. The fingerprint sensing chip is arranged in the gap, and is corresponding to the light-transmitting region of the optical component. The fingerprint sensing chip is electrically connected to the optical components. The packaging glue is arranged on the line carrier board, covers the optical component and the fingerprint sensing chip, and is exposed out of a light-output surface of the optical component. The size of the optical fingerprint sensing packaging structure is greatly reduced, the thickness is thin, and a micromation design demand can be met.

Owner:CHIPMOS TECH INC

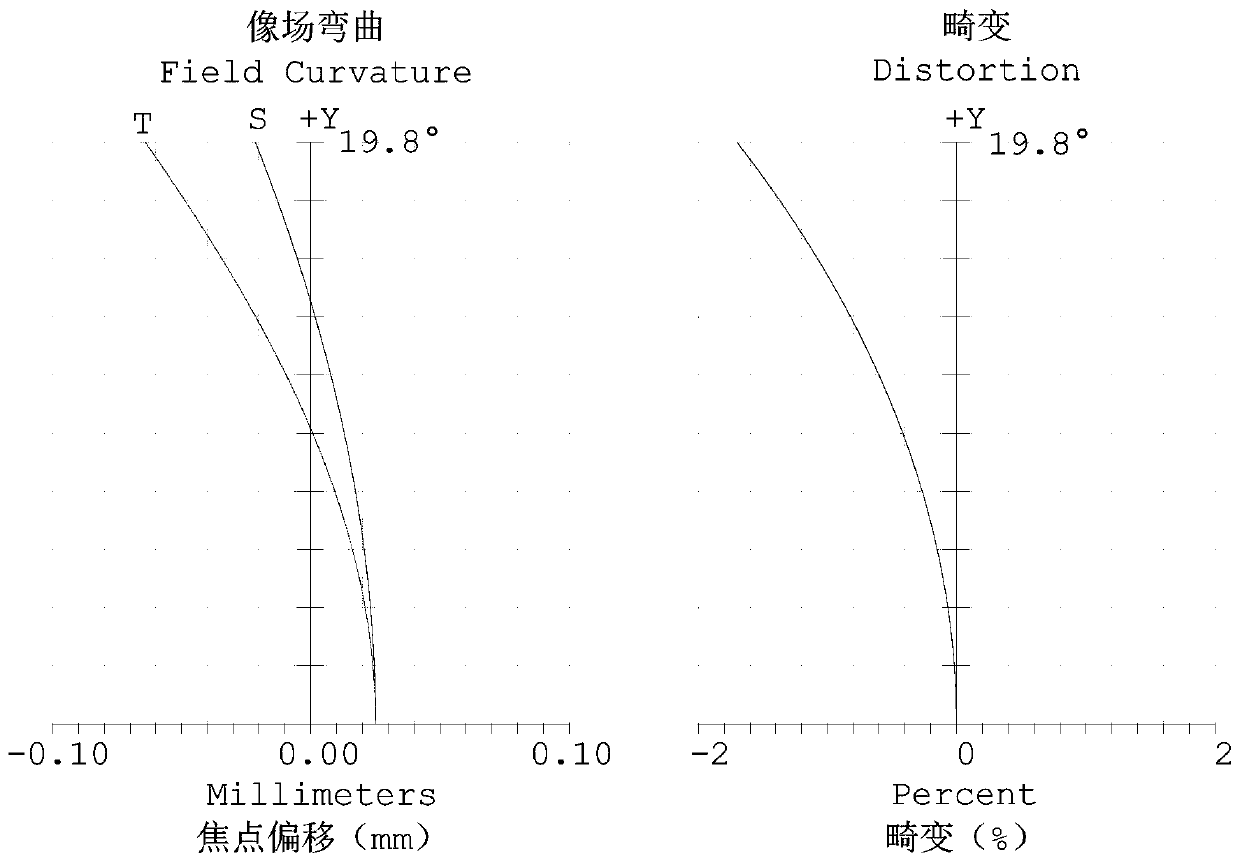

Optical systems, lens modules and electronics

ActiveCN113568150BMeet the needs of miniaturization designBig imageOptical elementsOphthalmologyOptical axis

An optical system, lens module and electronic equipment, the optical system sequentially includes from the object side to the image side along the optical axis: the first lens to the sixth lens with refractive power, wherein the first lens has positive refractive power, and the third lens has a positive refractive power. Lenses have negative refractive power. The object side of the first lens to the third lens is convex at the near optical axis, and the image side is concave at the near optical axis; the object side of the fourth lens and the image side of the fifth lens are both convex at the near optical axis. is a convex surface, and the image side of the sixth lens is concave at the near optical axis. The optical system satisfies the relation: 1.7

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

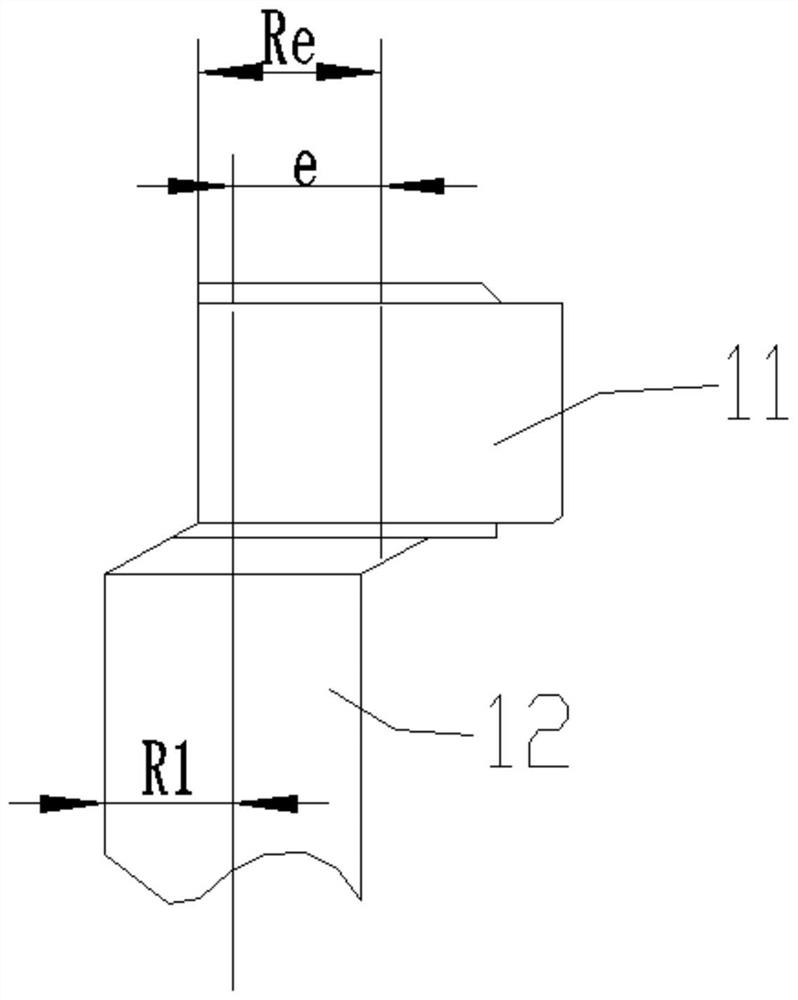

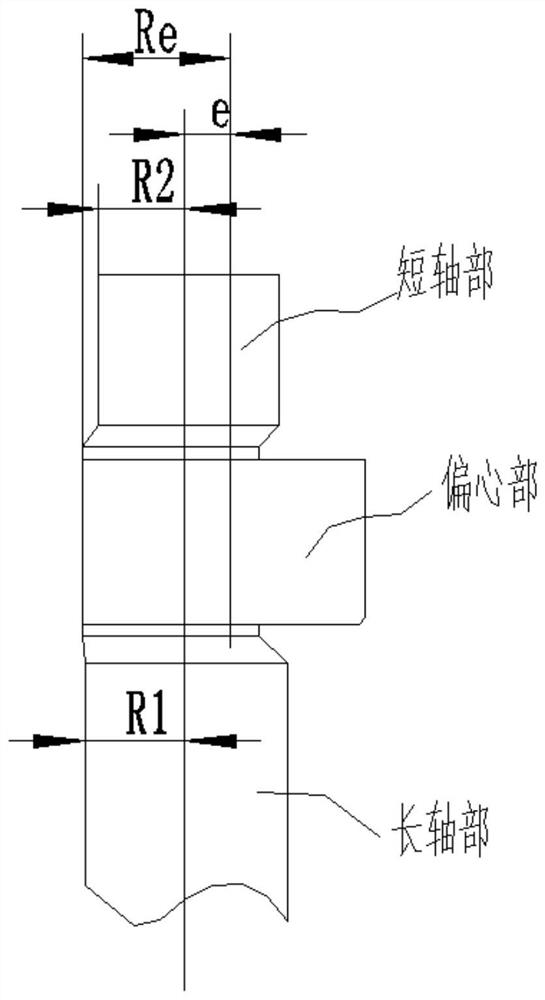

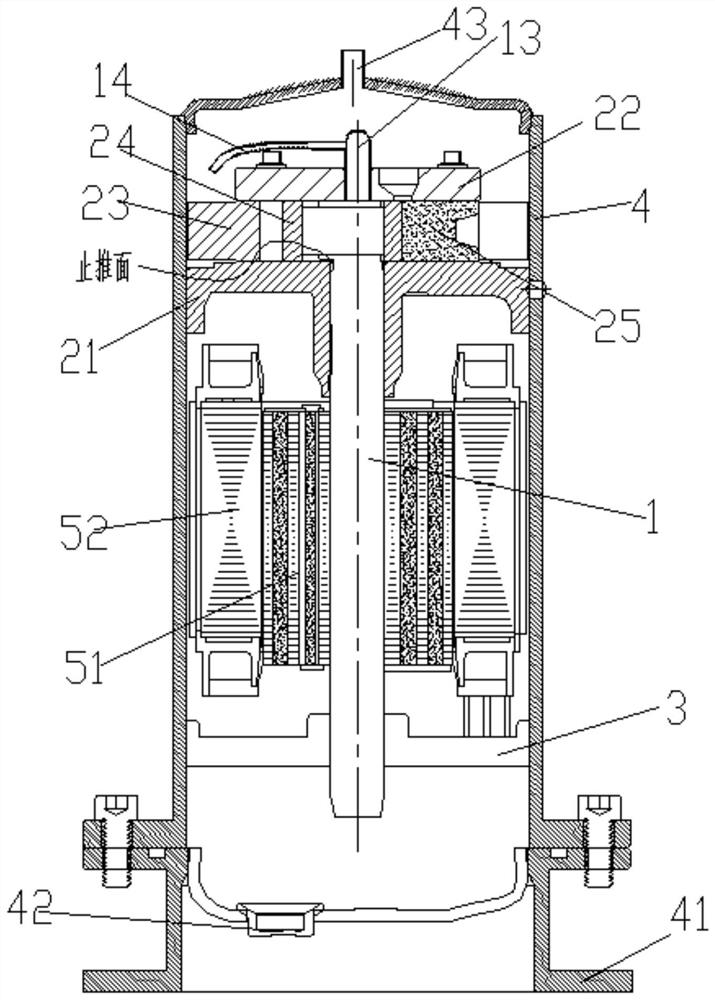

Crankshaft, rotor type compressor and air conditioner

PendingCN112746965AMeet the needs of large displacementMeet the needs of miniaturization designCompression machines with non-reversible cycleRotary/oscillating piston pump componentsControl theoryMechanical engineering

The invention provides a crankshaft, a rotor type compressor and an air conditioner. The crankshaft comprises an eccentric part and a rotating shaft section, wherein the rotating shaft section is located on a first end face of the eccentric part, and no protruding shaft section exists on a second end face of the eccentric part. According to the crankshaft, compared with a crankshaft in the prior art, the crankshaft is only provided with the rotating shaft section on one side of the eccentric part, so that the crankshaft objectively forms a short-shaft-free structure, therefore, the design on the aspect of a mounting structure of a roller is no longer subjected to condition limitation of min {R1, R2} in the prior art, and then the miniaturization design requirement of the compressor can be met while the large displacement requirement of the compressor is met.

Owner:GREE ELECTRIC APPLIANCES INC

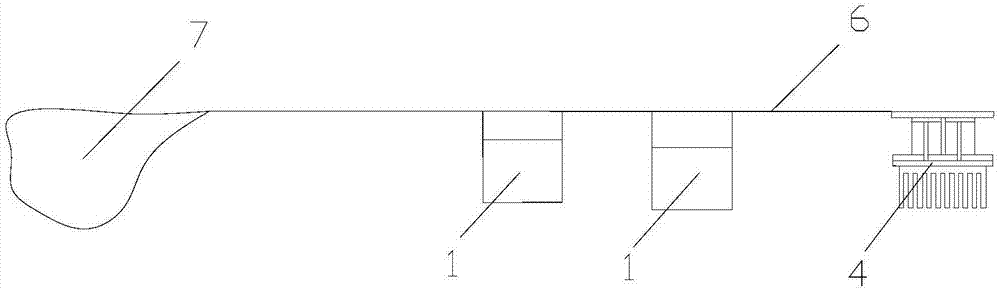

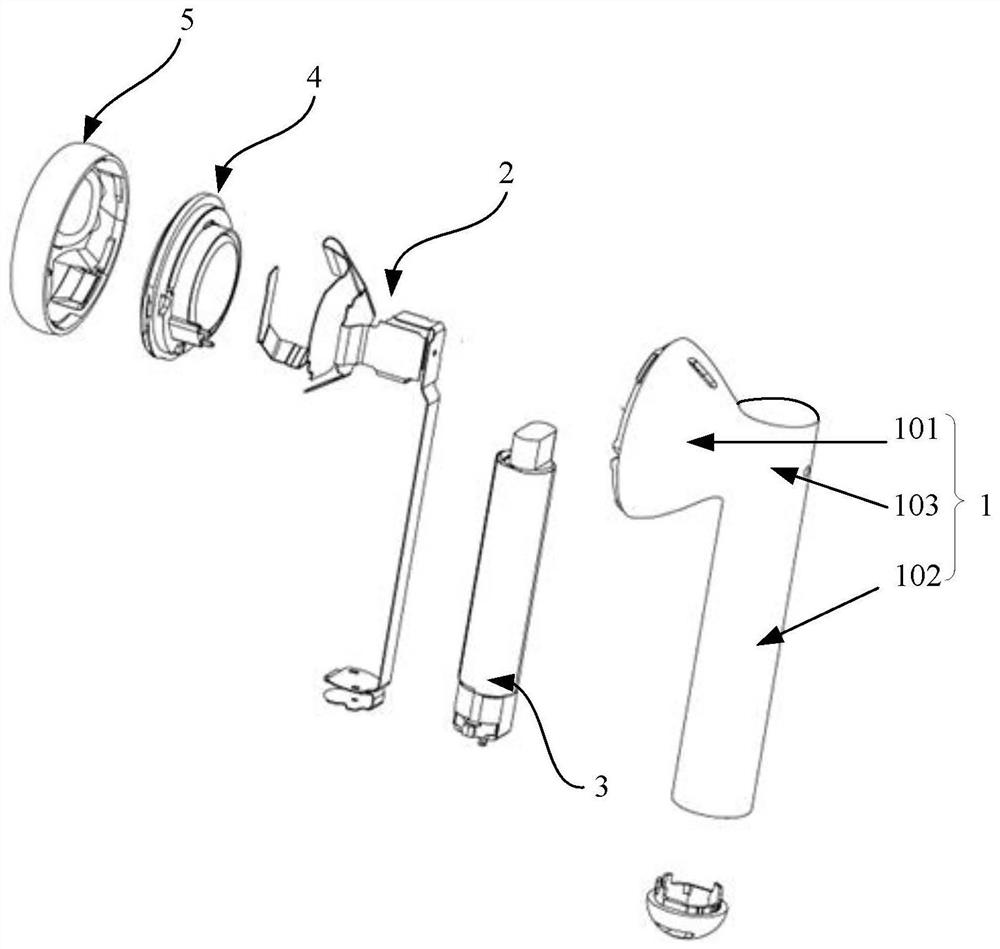

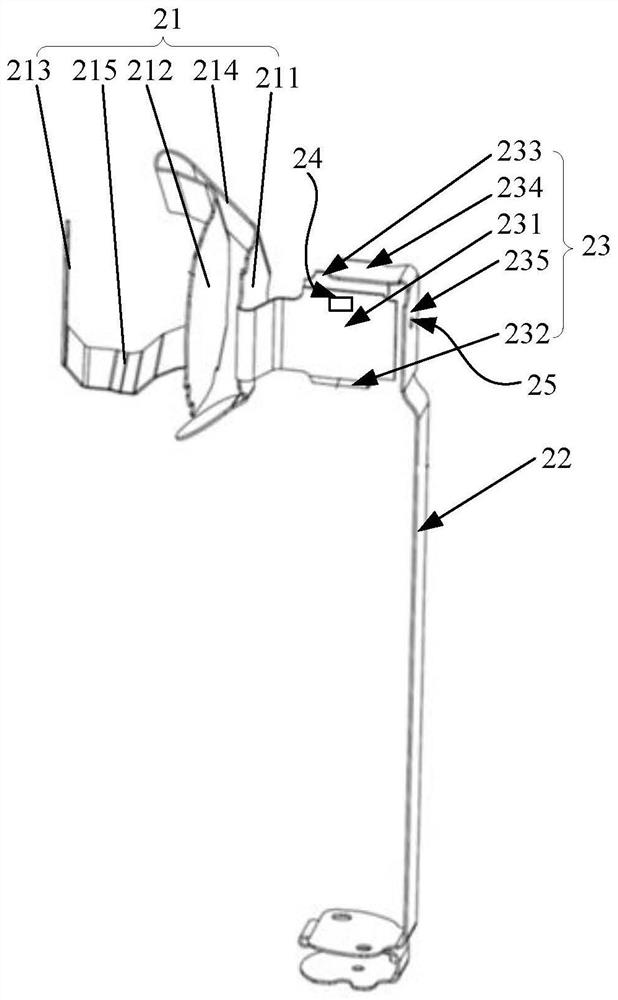

Antenna and Bluetooth wireless earphone

ActiveCN112582779AEfficient sending and receivingSmall footprintAntenna supports/mountingsRadiating elements structural formsTransceiverMiniaturization

The embodiment of the invention provides an antenna and a Bluetooth wireless earphone, and relates to the technical field of communication equipment. The antenna is arranged in the Bluetooth wirelessearphone, and a shell of the Bluetooth wireless earphone comprises an ear handle part, an ear plug part and a corner part, wherein a first circuit board is arranged in the ear plug part, a second circuit board is arranged in the ear handle part, the antenna comprises a first antenna arm, and the first antenna arm is laid on the first circuit board; the antenna also comprises a second antenna arm,the second antenna arm is laid on the second circuit board, and the first antenna arm and the second antenna arm are connected with the transceiver through a feed structure. According to the antenna and the Bluetooth wireless earphone provided by the embodiment of the invention, a bracket for arranging the first antenna arm and the second antenna arm does not need to be independently arranged, sothat the structure is simplified; meanwhile, the space occupied by the bracket is saved, and when the antenna is applied to the Bluetooth wireless earphone, the size of the Bluetooth wireless earphonecan be effectively reduced, so that the Bluetooth wireless earphone meets the miniaturization design requirement of electronic equipment.

Owner:HUAWEI TECH CO LTD

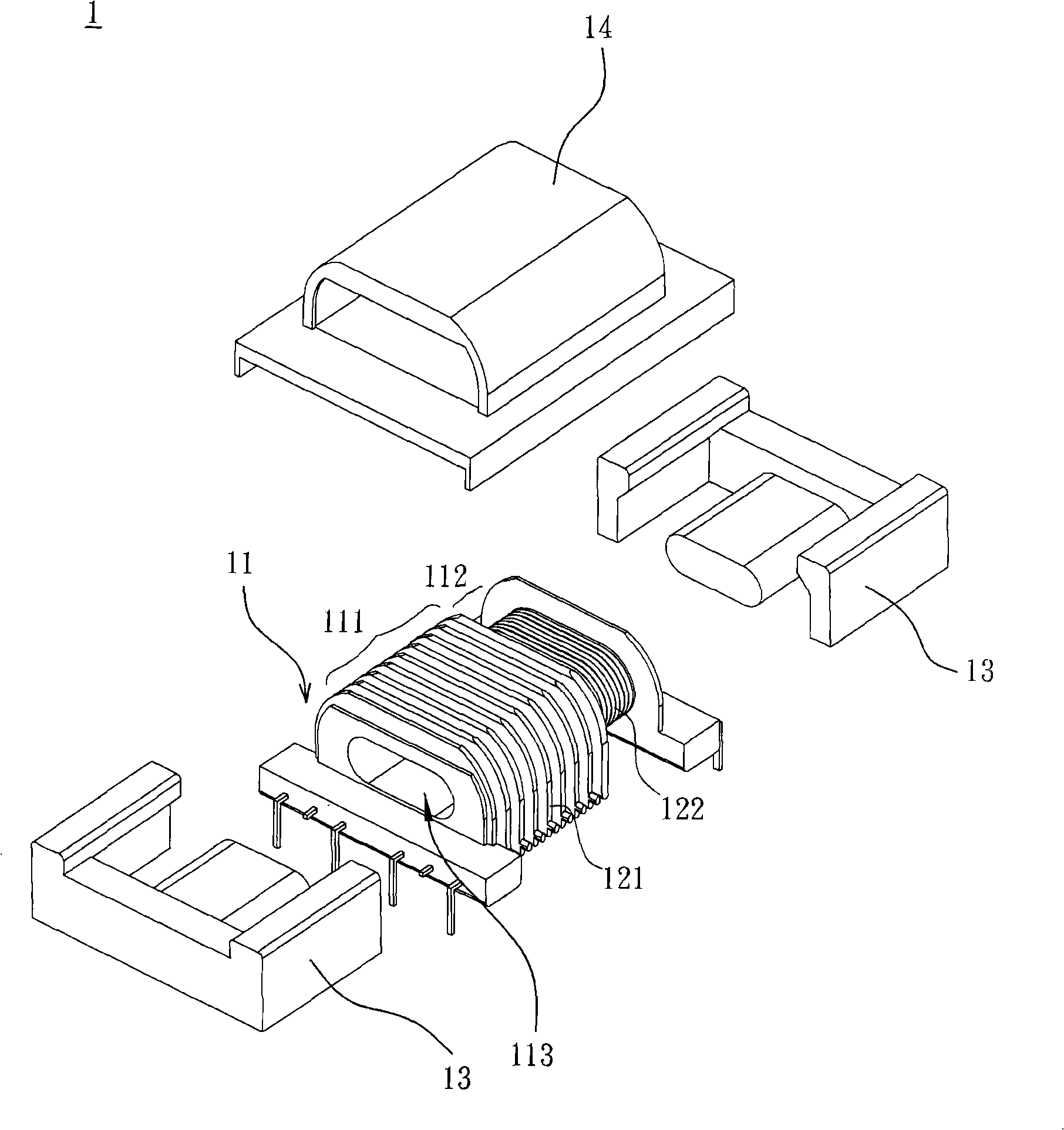

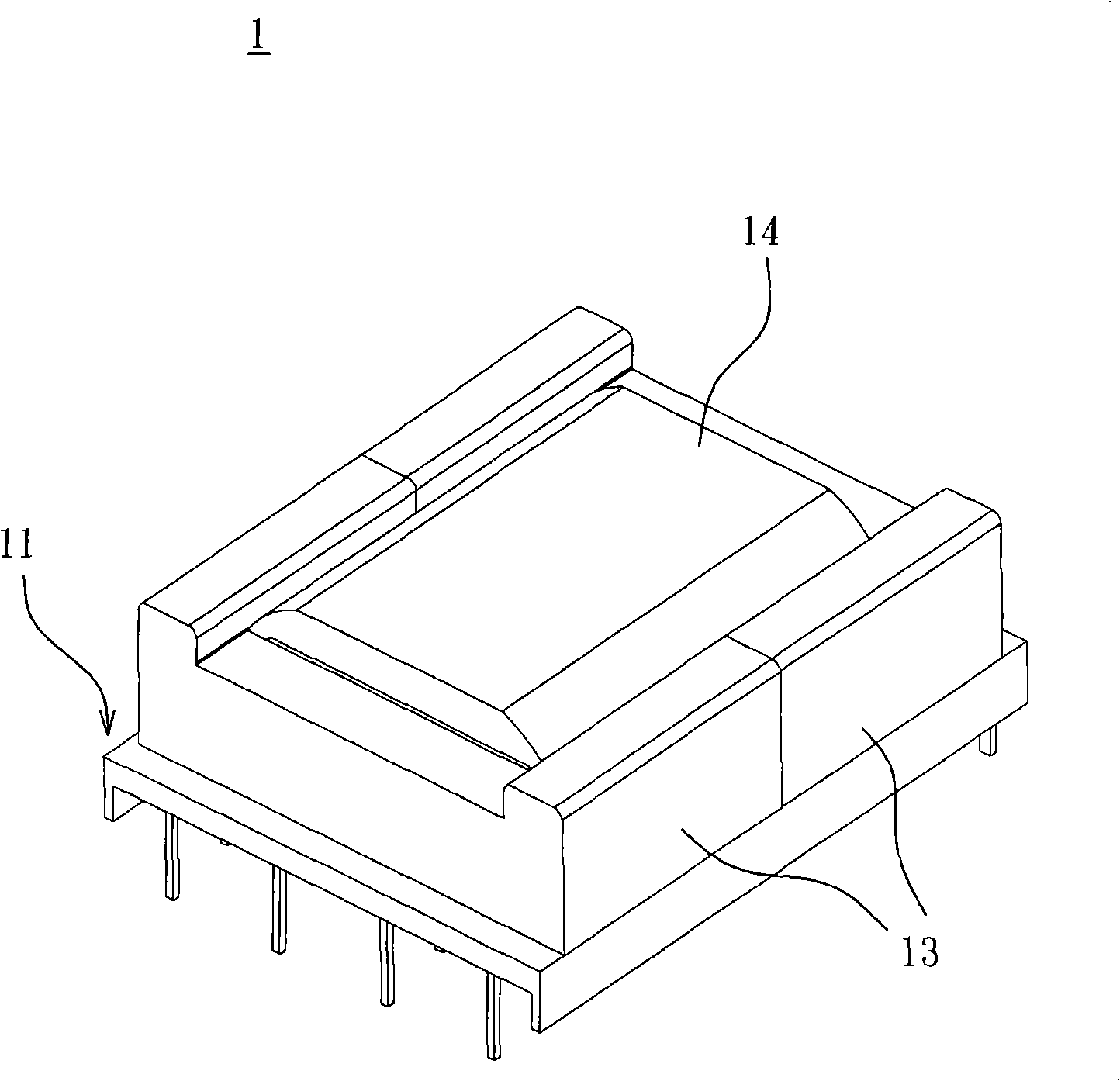

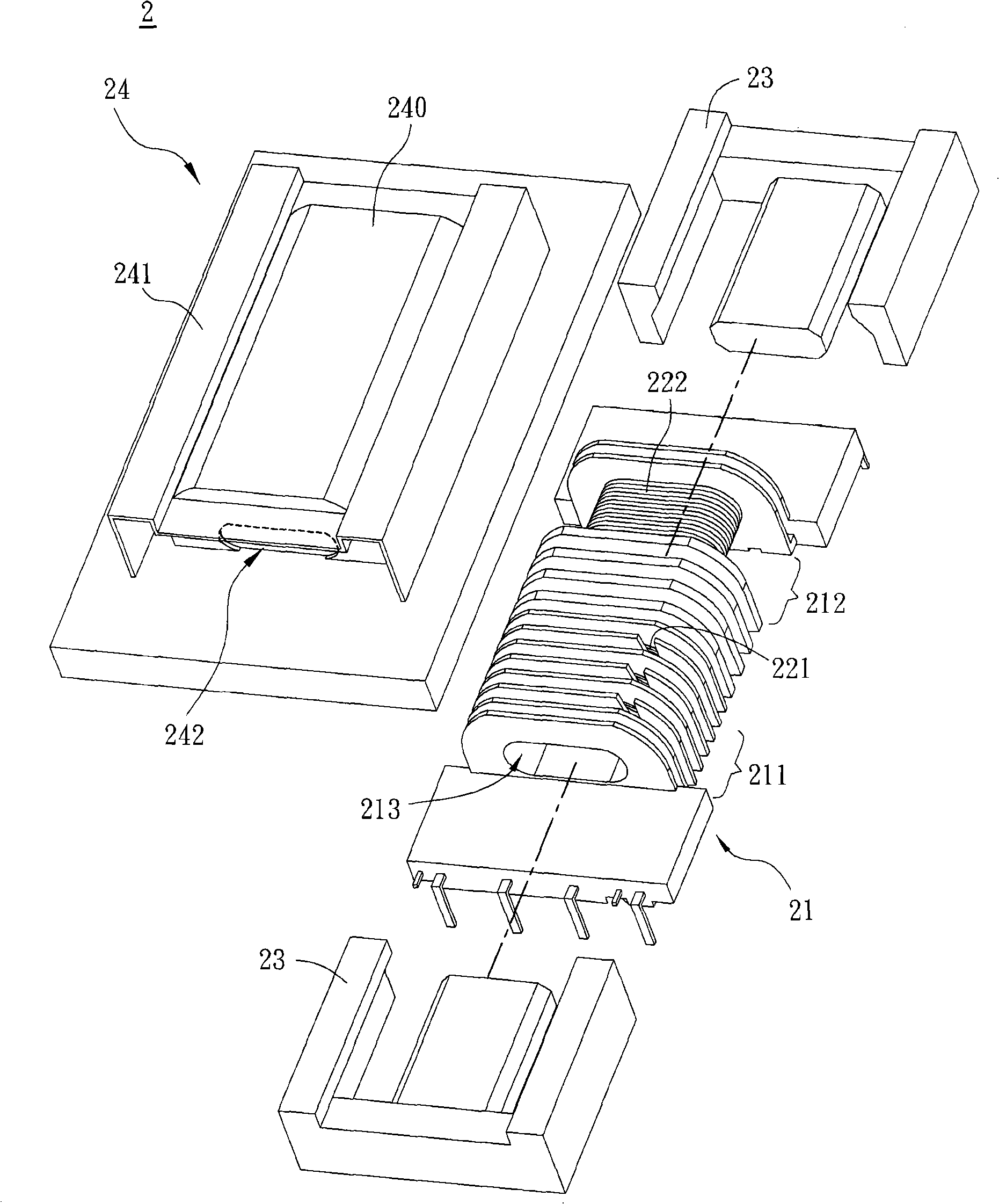

Transformer and its insulation cover

InactiveCN101320620ASmall sizeIsolated contactTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerEngineering

This invention discloses a transformer including a reel, a first winging, a second winging, a set of iron cores and an insulated cover. The reel includes a first winding area and a second winding area. The first winding is winded at the first winding area and the second winding is winded at the second winding area. The set of iron cores surrounds the first and second wiring. The insulated cover is covered at the reel and completely covers the set of the iron cores.

Owner:DELTA ELECTRONICS INC

Fingerprint identification module and electronic device

ActiveCN111144339AHigh strengthEasy to installPrint image acquisitionComputer hardwareFlexible circuits

The invention relates to a fingerprint identification module, which is characterized by comprising a flexible circuit board, a chip, a reinforcer and a cover plate, a base film layer and a combinationlayer which are stacked are arranged in the flexible circuit board, and a window is formed in the combination layer to expose part of the base film layer. The chip is arranged at the part, exposed out of the combined layer, of the base film layer. The reinforcer is arranged on the flexible circuit board, the reinforcer comprises a supporting part and an extending part, and the supporting part isarranged around the chip. The cover plate and the extending part are both arranged on one side, far away from the flexible circuit board, of the supporting part, and the cover plate covers the chip. And light can penetrate through the cover plate. The invention further relates to an electronic device comprising the fingerprint identification module. The size of the fingerprint identification module is small, and the requirement of miniaturization design can be met.

Owner:RECO TECH CHENGDU CO LTD

Optical system, lens module and electronic equipment

ActiveCN113568150AMeet the needs of miniaturization designBig imageOptical elementsOptical axisMiniaturization

The invention discloses an optical system, a lens module and an electronic device. The optical system includes the following parts in order from an object side to an image side along an optical axis: first to sixth lens elements having refractive power, wherein the first lens element has positive refractive power, and the third lens element has negative refractive power; the object-side surfaces of the first to third lenses are convex in a paraxial region, and the image-side surfaces of the first to third lenses are concave in a paraxial region; the object-side surface of the fourth lens element and the image-side surface of the fifth lens element are both convex in a paraxial region, and the image-side surface of the sixth lens element is concave in a paraxial region. The optical system satisfies the following relational expressions: 1.7 < EFL / Imgh < 2; wherein the EFL is the effective focal length of the optical system, and the Imgh is the image height corresponding to the maximum field angle of the optical system. Through reasonable design of the surface type and the refractive power of the first to the sixth lenses, the optical system satisfies the relational expression, so the optical system can realize a large-image-surface and high-definition telephoto shooting function while satisfying the miniaturization design.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Optical system, image capturing module and electronic device

PendingCN113741005AWith wide-angle characteristicsImprove image qualityOptical elementsOptic systemImage capture

The invention relates to an optical system, an image capturing module and an electronic device. The optical system includes: a first lens having negative refractive power; a second lens having refractive power, wherein the object side surface of the second lens is a convex surface; a third lens having positive refractive power, wherein the image side surface of the third lens is a convex surface; a fourth lens with negative refractive power; a fifth lens with positive refractive power; a sixth lens having positive refractive power, wherein the image side surface of the sixth lens is a convex surface; and a seventh lens having negative refractive power, wherein the object side surface of the seventh lens is a concave surface. The optical system satisfies the following conditions shown in the description, wherein f2 is the effective focal length of the second lens, and f1 is the effective focal length of the first lens. The optical system has the wide-angle characteristic and can meet the requirement of large-range shooting.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

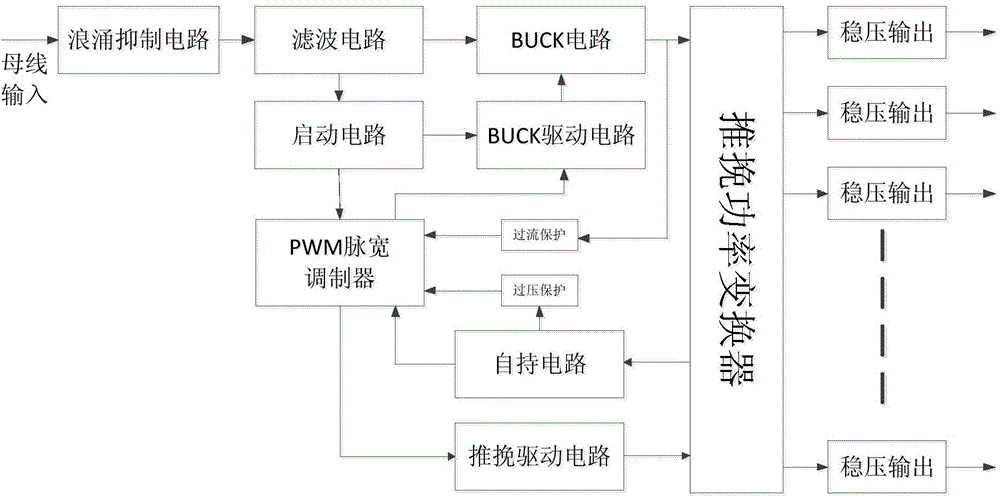

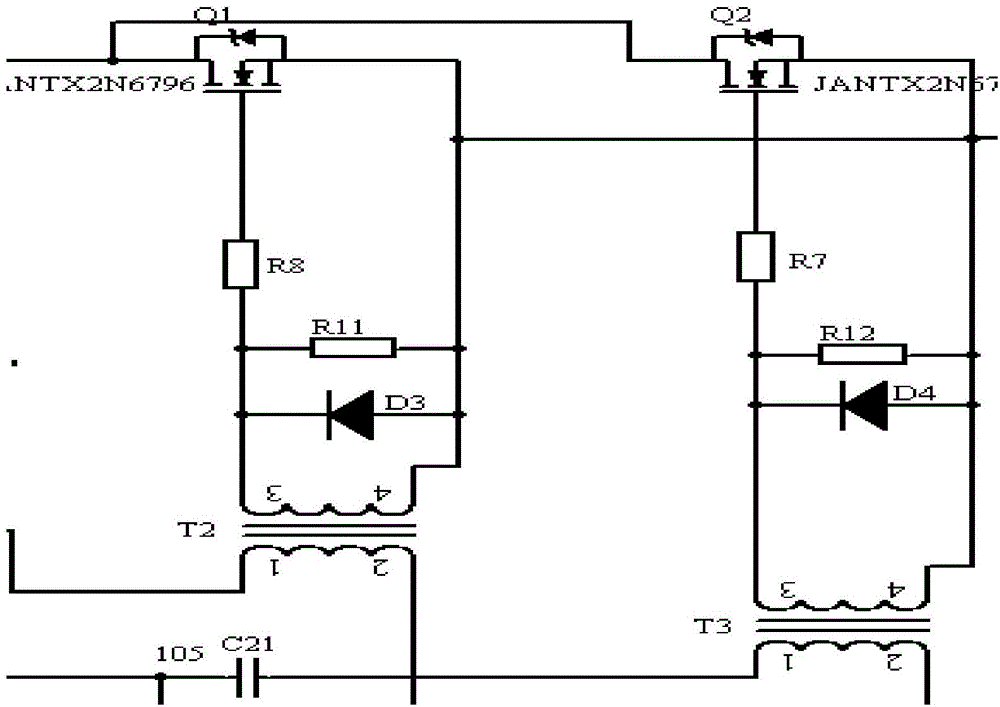

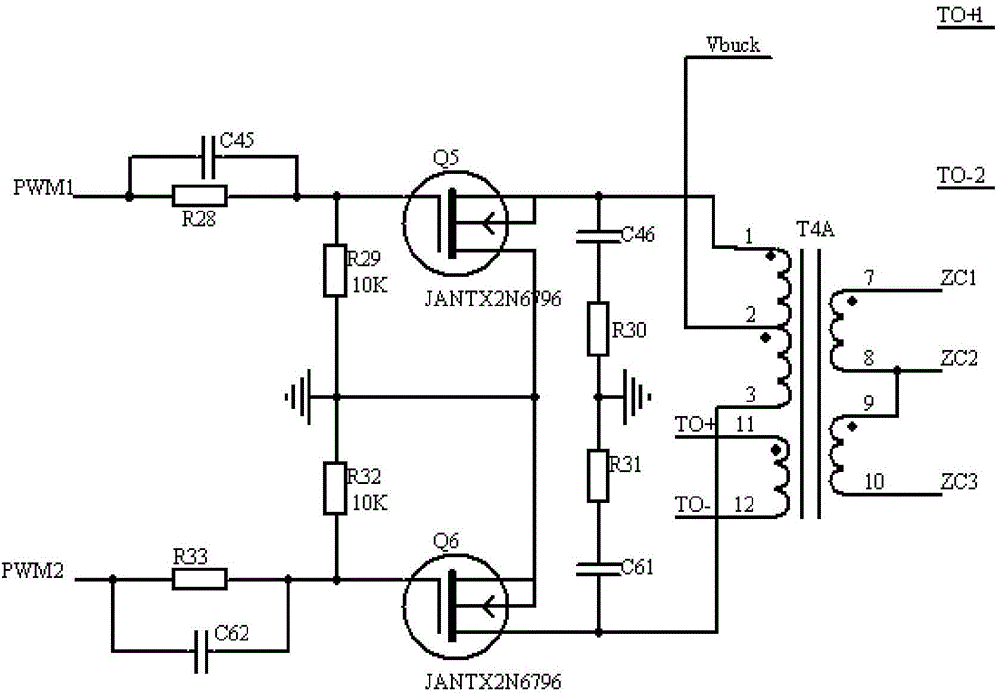

Multi-channel controllable isolated output secondary power module

InactiveCN105763068AMeet needsMiniaturizationDc-dc conversionElectric variable regulationPush pullComputer module

The invention relates to a multi-channel controllable isolated output secondary power module and belongs to the technical field of satellite power sources. The multi-channel controllable isolated output secondary power module is characterized in that the module includes a surge inhibiting circuit, an input filtering circuit, a BUCK drive circuit, a push-pull isolation power change circuit, a PWM control circuit and a rectification output circuit; after a 28V bus is connected to a secondary power source, the first filtering is performed by the input filtering circuit and then multi-channel isolation plus 12V power change is implemented through the BUCK drive circuit and the voltage reducing push-pull isolation power change circuit, and the rectification output circuit supplies power for an SE manager. The multi-channel controllable isolated output secondary power module provided by the invention has advantages of small size, low weight, simple structure, high safety, high reliability, good expansion capability, wide application range and the like and multi-channel rear-stage output can be realized.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com