Optical lens, camera module and electronic equipment

An optical lens and lens technology, applied in optics, optical components, instruments, etc., can solve problems such as the inability to meet the miniaturization design of optical lenses, the inability to meet customer shooting needs, the small amount of light entering the optical lens, etc., to shorten the total optical length, meet the Miniaturized design, the effect of improving the field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

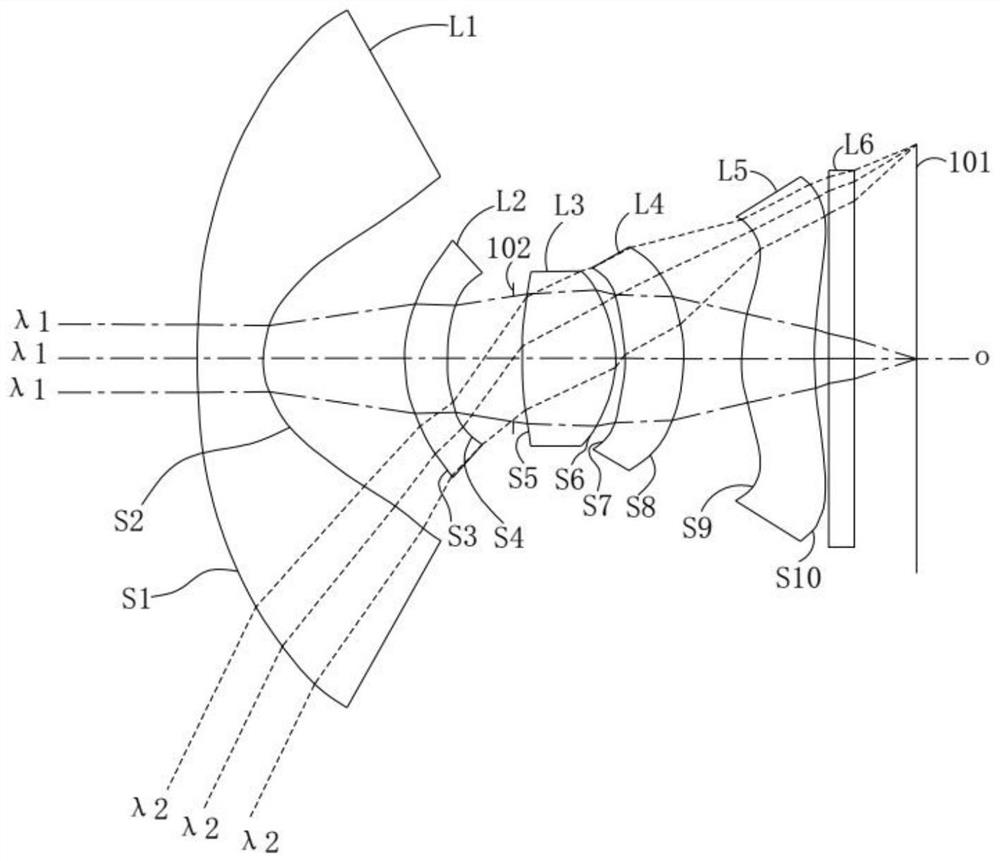

[0068] see figure 1 , the optical lens 100 includes a first lens L1, a second lens L2, a diaphragm 102, a third lens L3, a fourth lens L4, a fifth lens L5 and a filter arranged in sequence from the object side to the image side along the optical axis o L6. For the materials of the first lens L1 , the second lens L2 , the third lens L3 , the fourth lens L4 and the fifth lens L5 , please refer to the description of the above-mentioned specific embodiments, and details are not repeated here.

[0069] Further, the first lens L1 has negative refractive power, the second lens L2 has positive refractive power, the third lens L3 has positive refractive power, the fourth lens L4 has negative refractive power, and the fifth lens L5 has positive refractive power.

[0070] Furthermore, the object side S1 and the image side S2 of the first lens L1 are respectively convex and concave at the near optical axis o. The object side S3 and the image side S4 of the second lens L2 are respectivel...

no. 2 example

[0093] see Figure 4 , Figure 4 It is a schematic structural diagram of the optical lens 100 according to the second embodiment of the present application, and shows the optical paths of the first light beam λ1 and the second light beam λ2 . The optical lens 100 includes a first lens L1, a second lens L2, a diaphragm 102, a third lens L3, a fourth lens L4, a fifth lens L5 and a filter L6 arranged in sequence from the object side to the image side along the optical axis o . For the materials of the first lens L1 , the second lens L2 , the third lens L3 , the fourth lens L4 and the fifth lens L5 , please refer to the description of the above-mentioned specific embodiments, and details are not repeated here.

[0094] Further, in the second embodiment, the refractive power of each lens and the surface shape at the near optical axis o are respectively the same as the refractive power of each lens and its surface shape at the near optical axis o in the first embodiment .

[009...

no. 3 example

[0110] see Figure 7 , Figure 7 It is a schematic structural diagram of the optical lens 100 according to the third embodiment of the present application. The optical lens 100 includes a first lens L1, a second lens L2, a diaphragm 102, a third lens L3, a fourth lens L4, a fifth lens L5 and a filter L6 arranged in sequence from the object side to the image side along the optical axis o . For the materials of the first lens L1 , the second lens L2 , the third lens L3 , the fourth lens L4 and the fifth lens L5 , please refer to the description of the above-mentioned specific embodiments, and details are not repeated here.

[0111] Further, in the third embodiment, the refractive power of each lens and the surface shape at the near optical axis o are respectively the same as the refractive power of each lens and its surface shape at the near optical axis o in the first embodiment .

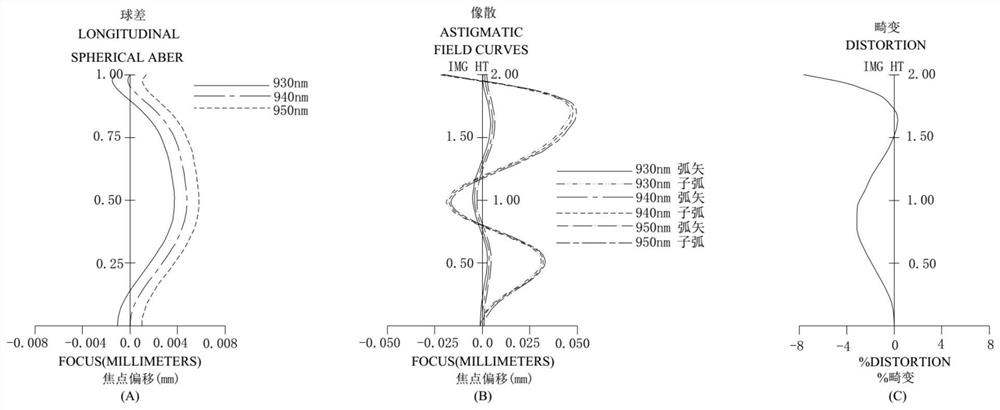

[0112] In the third embodiment, with the aperture number Fno=1.45 of the optical lens 100, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com