Grid type control drum device of small fast neutron reactor

A grid type, fast neutron technology, applied in the control of nuclear reactions, reactors, reduction of greenhouse gases, etc., can solve the problems of large radial space, stuck, unfavorable device miniaturization, etc., to achieve small axial space, expansion Good adaptability, not easy to deform and get stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

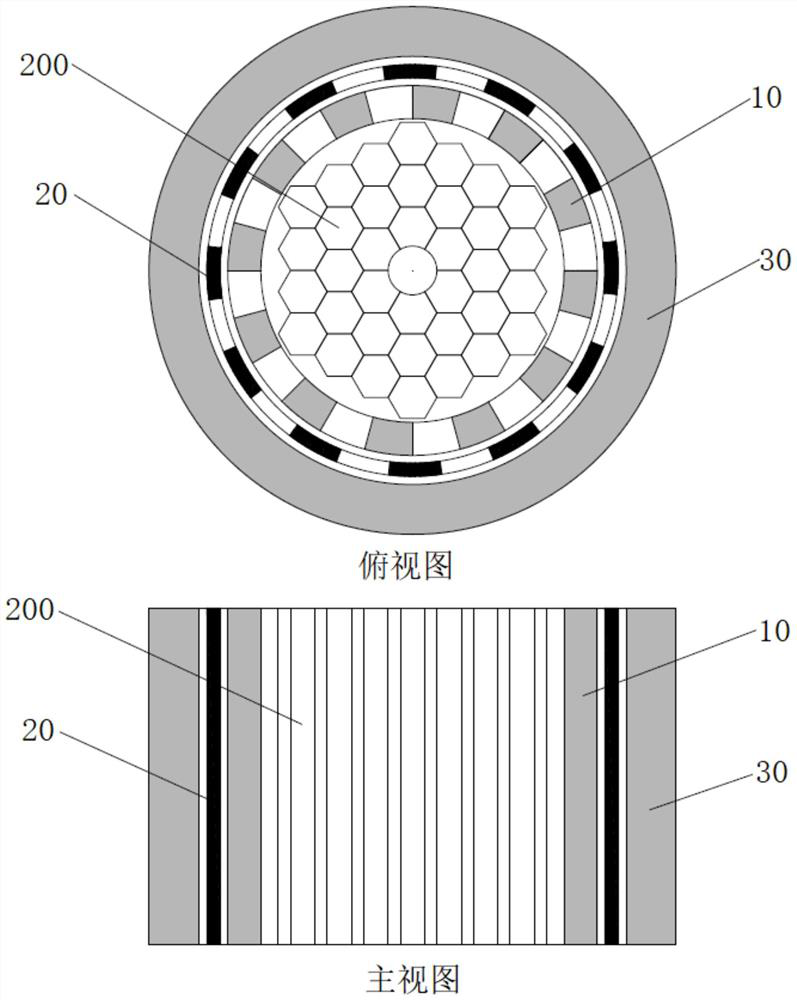

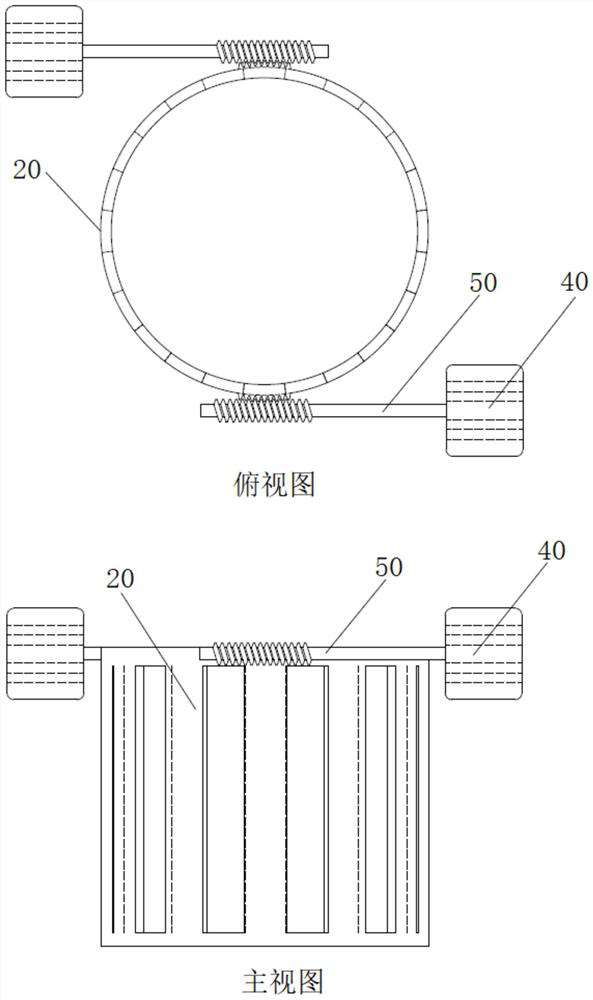

[0025] Such as figure 1 As shown, a small fast neutron reactor grid control drum device provided by the present invention consists of an inner reflector arranged around the core, a grid control drum, an outer reflector, a drive motor and a worm. The first layer outside the core is the internal reflection layer, which is cylindrical and grid-shaped, and its position is fixed and cannot be rotated. The main material of the reflection layer is BeO, which is encapsulated by a radiation-resistant metal cladding, and the gap between the grids is hollow; the middle layer It is a grid-type control drum, which is cylindrical and grid-shaped, and can rotate at a certain angle under the drive of the drive motor. The main material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com