Transformer and its insulation cover

A transformer and insulating cover technology, applied in the field of transformers, can solve the problems of insufficient distance, inability to effectively isolate, increase the size of the winding frame 11, etc., and achieve the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The transformer and its insulating cover of the preferred embodiment of the present invention will be described below with reference to the relevant drawings, wherein the same components will be described with the same reference symbols.

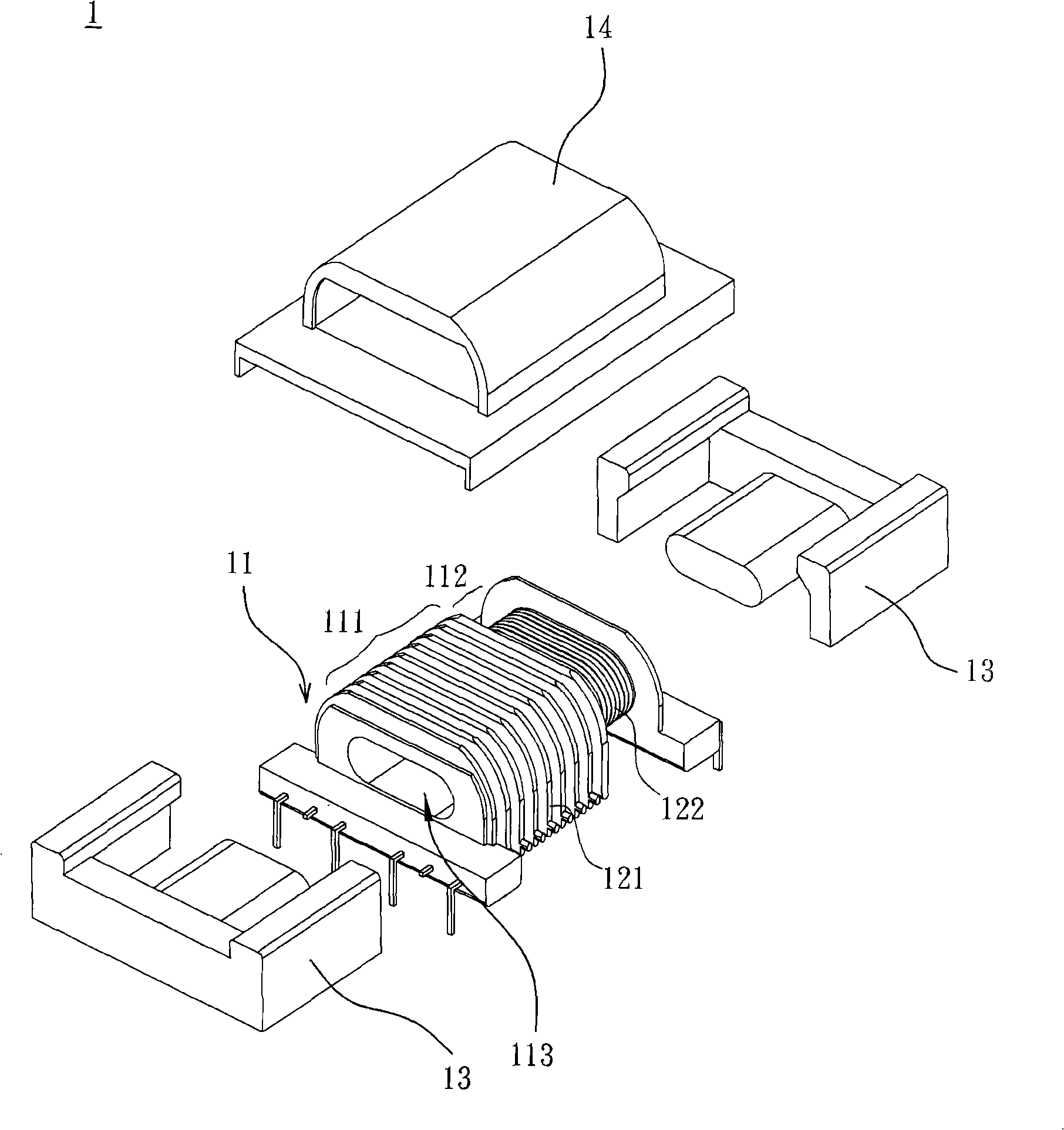

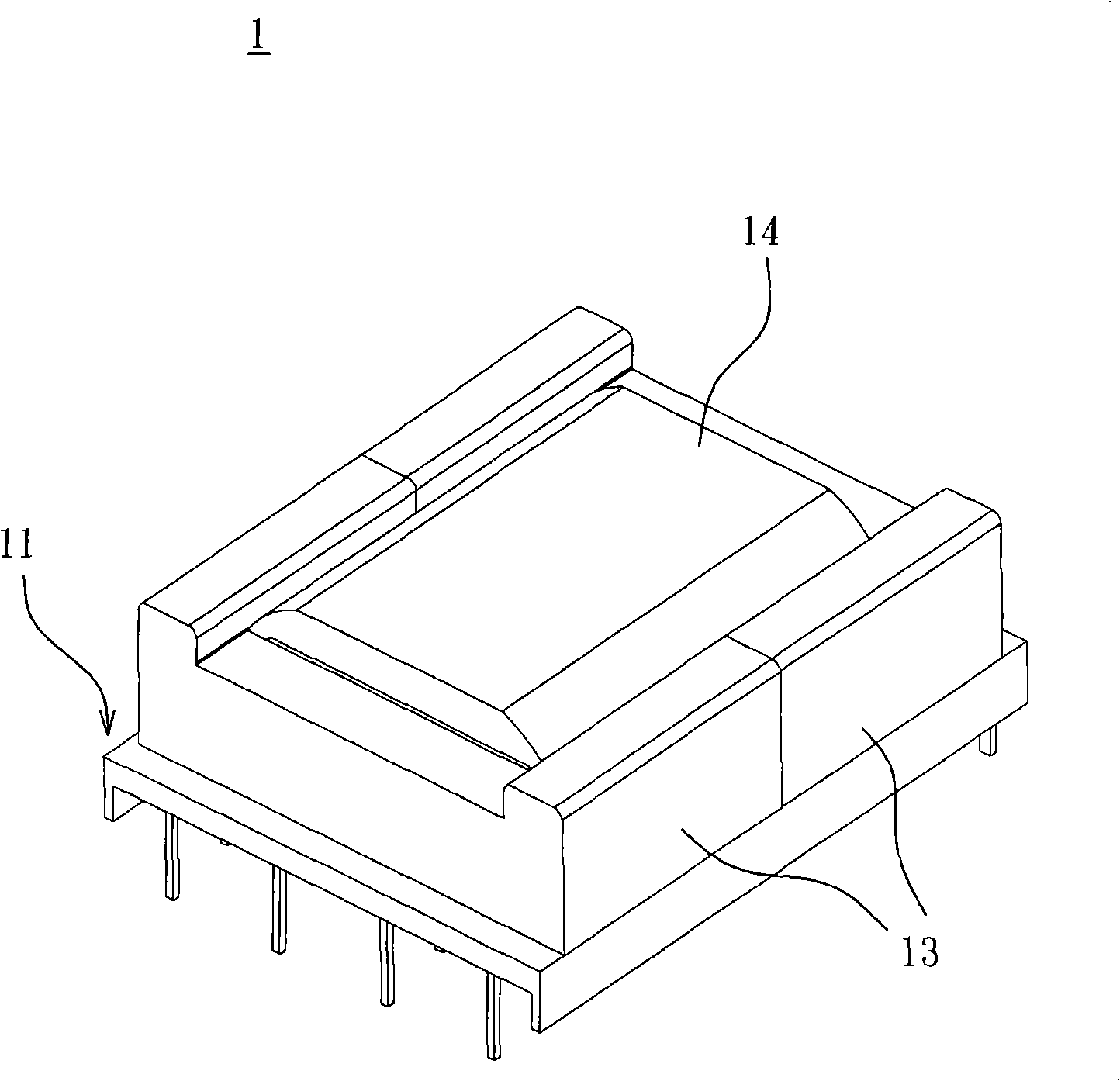

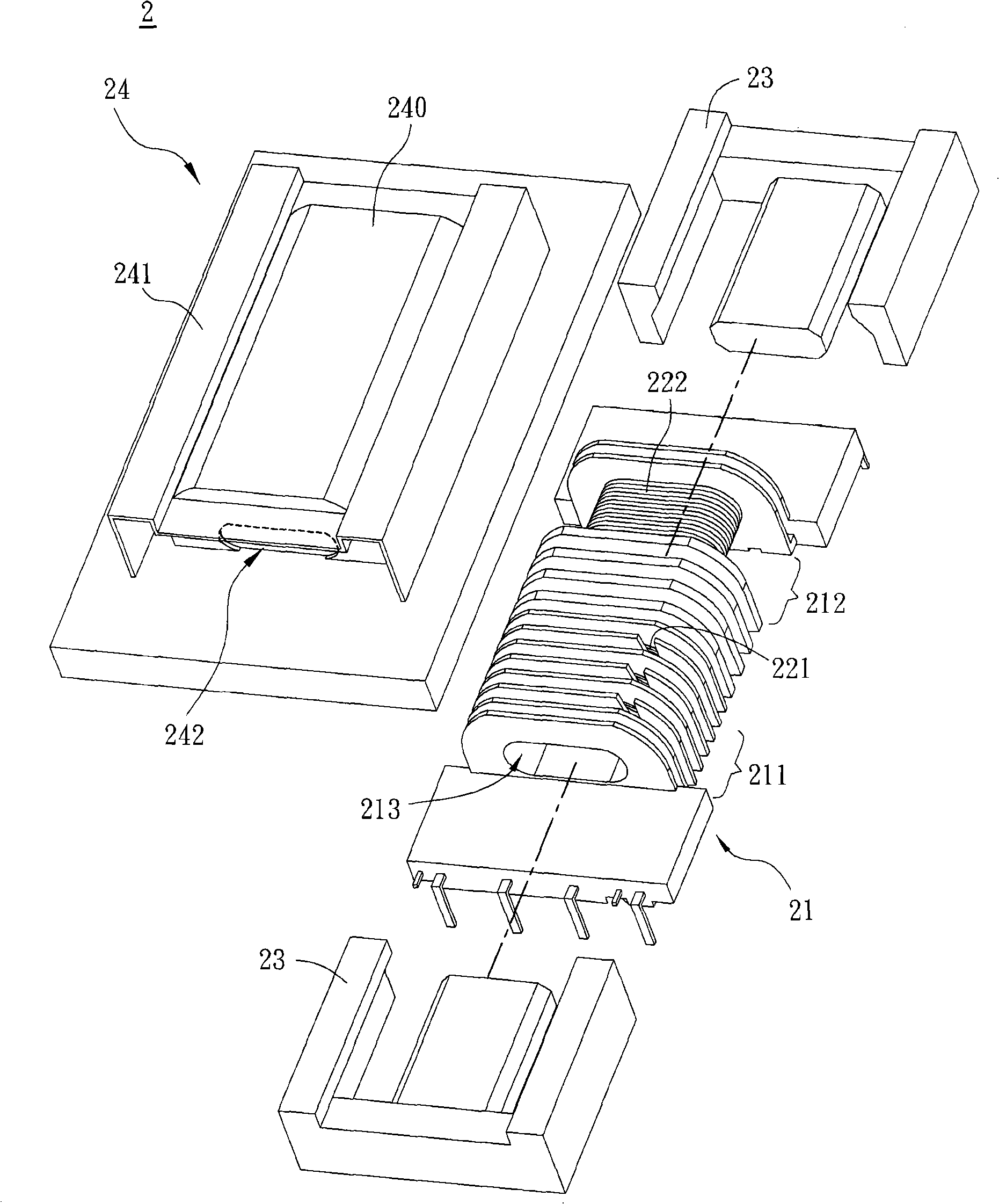

[0023] Please refer to image 3 and Figure 4 As shown, the transformer 2 of the preferred embodiment of the present invention includes a winding frame 21 , two sets of winding wires 221 , 222 , an iron core set 23 and an insulating cover 24 . The winding frame 21 has two winding areas 211 , 212 and a through hole 213 . The winding wire 221 is wound on the winding area 211 , and the winding wire 221 can be used as a primary side winding or a voltage input end. The winding wire 222 is wound on the winding area 212 , and the winding wire 222 can be used as a secondary side winding or a voltage output terminal. According to the actual application, the winding 221 can be changed into a secondary side winding, and the winding 222 can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com