Crankshaft, rotor type compressor and air conditioner

A technology of rotor compressors, applied in the fields of rotor compressors, crankshafts, and air conditioners, which can solve the problems that compressors cannot meet the requirements of large displacement and miniaturization at the same time, and the installation structure of pistons is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

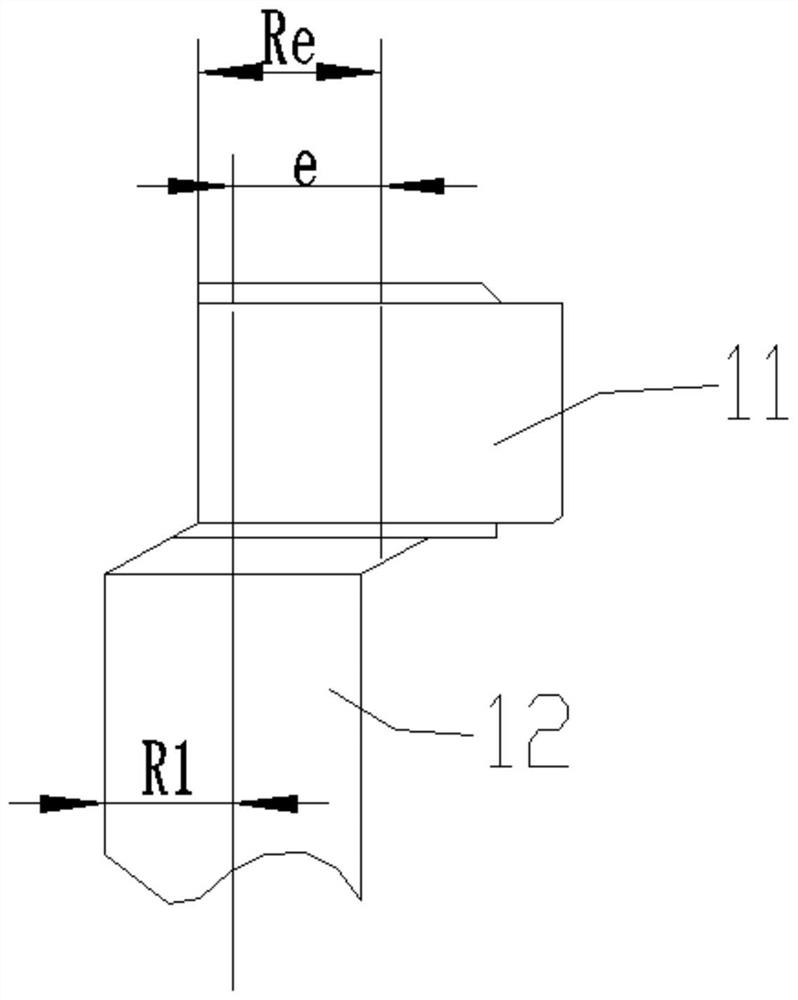

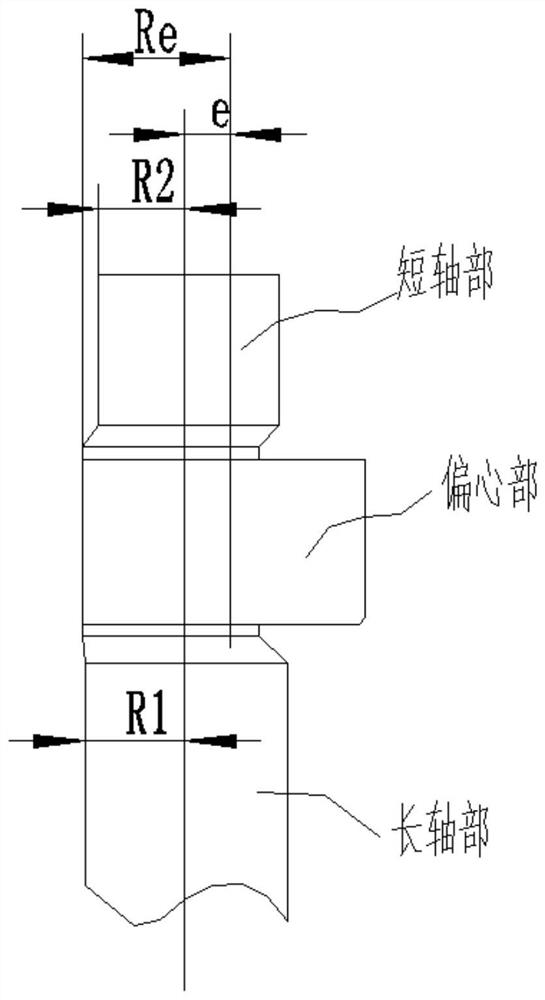

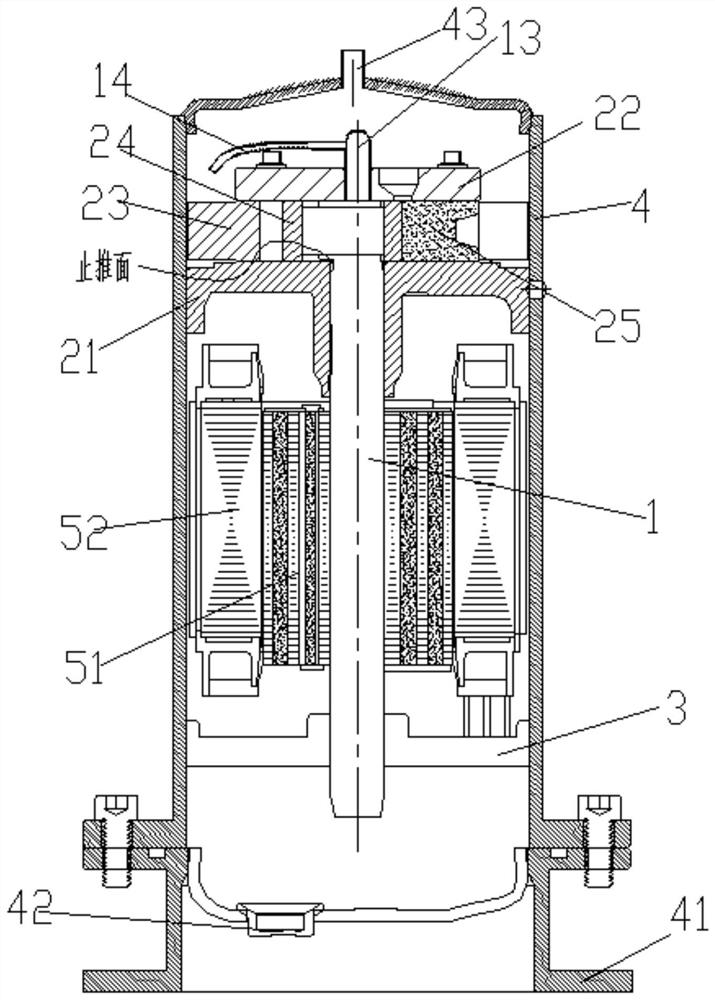

[0028] see in conjunction Figure 1 to Figure 9 As shown, according to an embodiment of the present invention, a crankshaft is provided, including an eccentric portion 11 and a shaft section 12, the shaft section 12 is located on the first end surface of the eccentric portion 11 and the second end surface of the eccentric portion 11 There is no protruding shaft section. In this technical solution, compared with the crankshaft in the prior art, the crankshaft is only provided with the rotating shaft section 12 on one side of the eccentric part 11 so that the crankshaft objectively forms a structure without a short shaft, so The design of the installation structure of the roller 24 (also known as the piston) is no longer limited by the min{R1, R2} conditions in the prior art, and thus can meet the compressor's large displacement requirements while meeting the compressor's requirements. miniaturization design requirements.

[0029] specific, figure 1 Shows the local structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com