Adjustable rubber bearing and its installation method and adjustment method

A rubber bearing, adjustable technology, applied in bridge materials, construction, bridge construction and other directions, to achieve the effect of long service life, easy installation, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

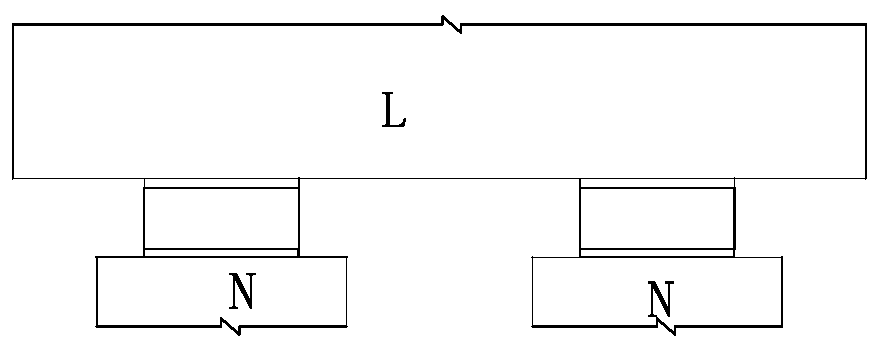

[0063] The basin type rubber bearing has the following structure.

[0064] The upper support plate 100, the upper support plate 100 is welded steel plate, such as Q235 steel plate welded, including the horizontal plate part and the surrounding steel plate, the surrounding steel plate is welded on the lower surface of the horizontal plate, forming an enclosed area I101 , this area is used to fit the sliding liner 102. Usually, the liner uses a polyurethane board. In the present invention, the sliding liner 102 is a composite structure, which is made of polyurethane and a lead core board. That is to say, a lead core board is compounded inside the polyurethane board, and the lead core board has good shock absorption performance. In one of the preferred modes, the polyurethane board is pre-bonded in the area I by using asphalt as an adhesive to form an integrated structure, which facilitates the installation process.

[0065] Rubber shock absorber 200, the rubber shock absorber 2...

Embodiment 2

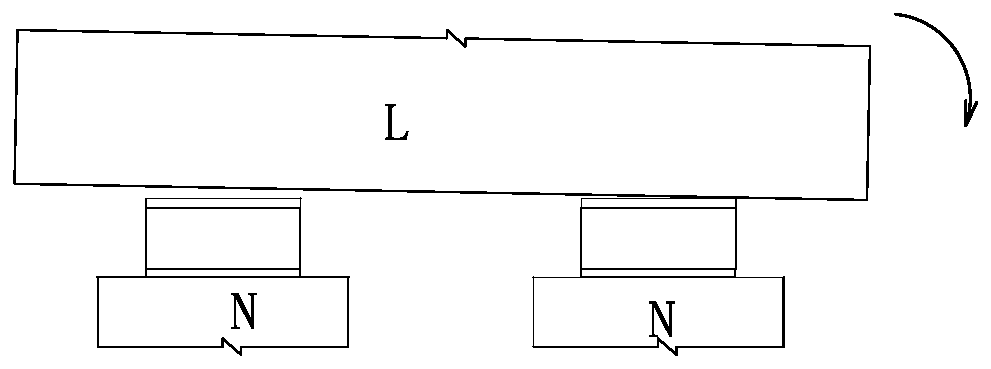

[0085] In this embodiment, the height of the surrounding steel plates in the upper and lower support plates is extended to form overlapping structures. The existence of overlapping structures can effectively ensure the safety of the upper and lower support plates, avoid slipping out, and form a safe For protection, under this structure, the elastic body setting on both sides can be omitted, further simplifying the structure setting.

Embodiment 3

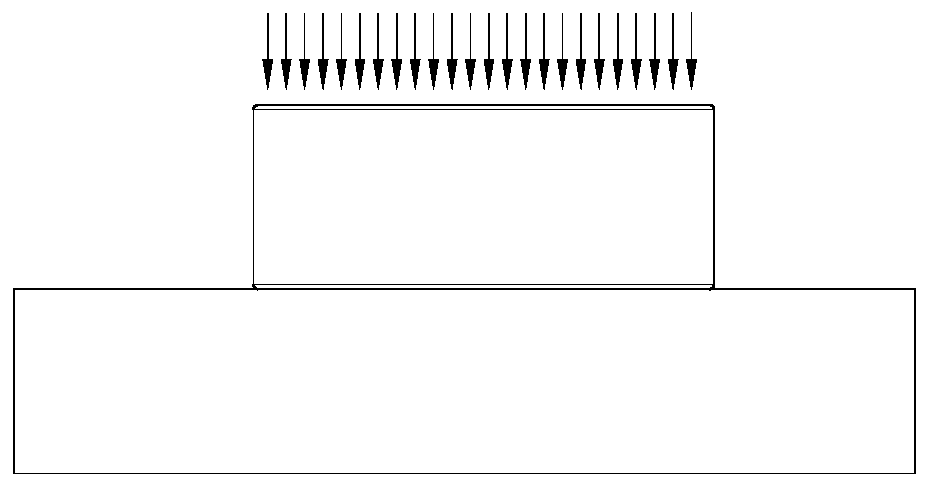

[0087] On the basis of Embodiment 1, the rubber shock absorber 200 is improved, and a through hole penetrating from top to bottom is provided in the rubber shock absorber. There are a plurality of through holes, which are evenly arranged inside the rubber shock absorber. A lead rod or brass rod 204 is inserted into each through hole. Since this metal rod has better rigidity than rubber, under non-vibrating conditions, the metal rod can share the weight of the bridge body, which can effectively reduce the The load bearing of the rubber improves the service life of the rubber bearing.

[0088] In this embodiment, considering the large deformation capacity of the rubber shock absorber, the height of the metal rod is about 10% to 5% lower than that of the rubber shock absorber, so that the combined advantages of the metal rod and the rubber material can be fully utilized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com