Automobile rearview mirror

A technology for automotive rearview mirrors and lenses, applied in the field of rearview mirrors, can solve the problems that the lens brackets and lenses are prone to shake, affect driving safety, and have poor stability, so as to eliminate hidden dangers of driving, avoid shaking, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

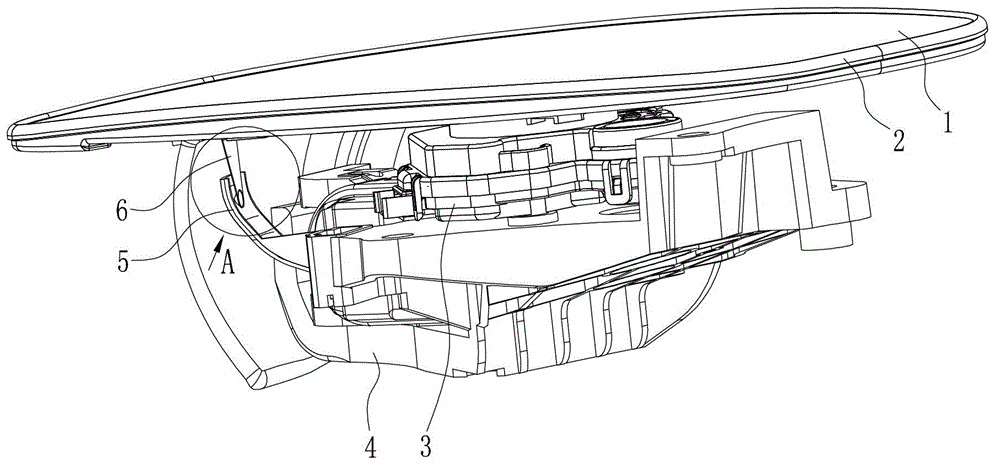

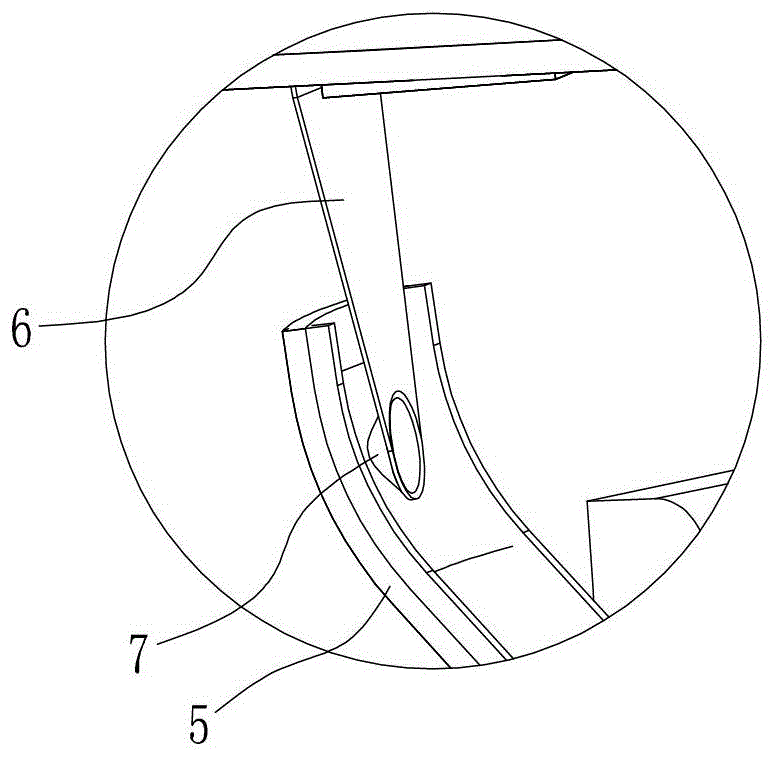

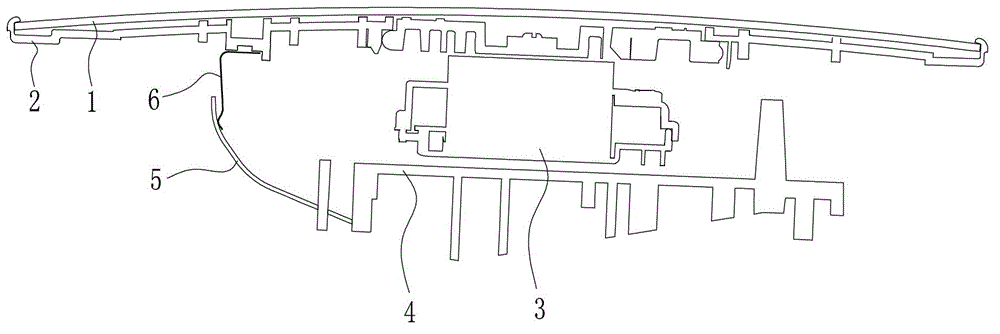

[0018] like figure 1 , figure 2 , image 3 , Figure 4 Shown, the present invention is made of lens 1, lens bracket 2, lens adjustment mechanism 3, adjustment mechanism bracket 4, support piece 5, reed 6 and cone head 7 etc. Wherein, the lens 1 is supported by the edge of the lens bracket 2, and the lens adjustment mechanism 3 is installed on the back of the lens bracket 2. The lens adjustment mechanism 3 is fixedly installed on the adjustment mechanism bracket 4, and the adjustment mechanism bracket 4 and the lens bracket 2 live separately in the both sides of eyeglass adjusting mechanism 3. The structure and working principle of the lens adjusting mechanism 3 are the same as those of the prior art, and will not be repeated here. The connection methods of the related parts of the lens 1, the lens bracket 2, the lens adjustment mechanism 3 and the adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com