Box-type member turn-over lifting appliance with oversized cross section and application method thereof

A cross-section and box-shaped technology, which is applied in the field of turning spreaders, can solve problems such as low safety factor, component deformation, and base material damage, and achieve the effects of improving work efficiency, using safety, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

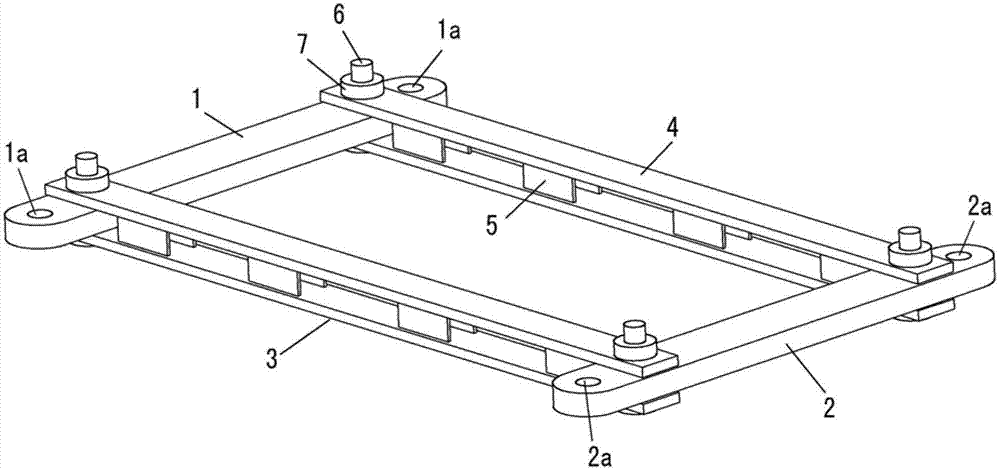

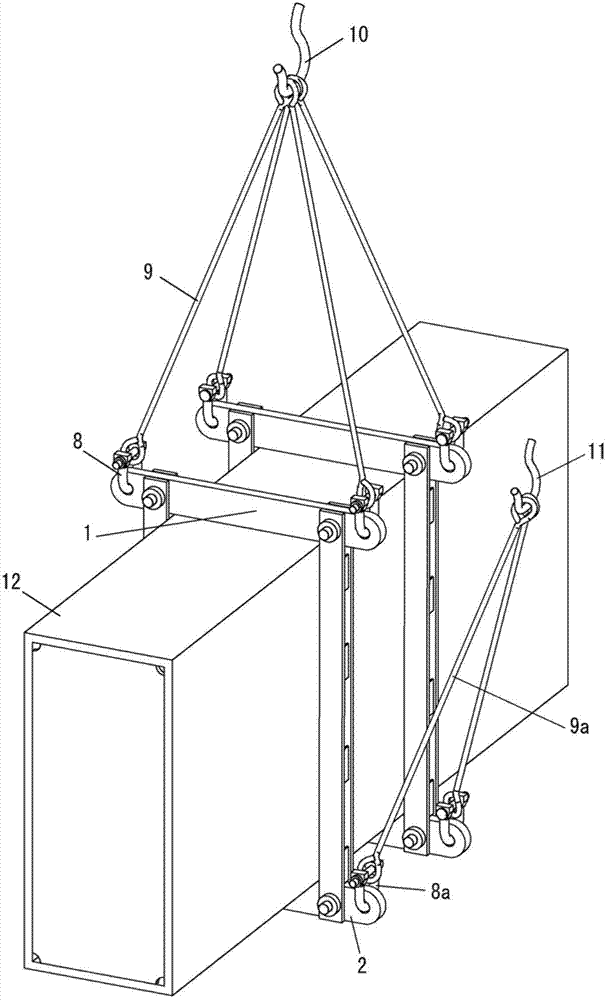

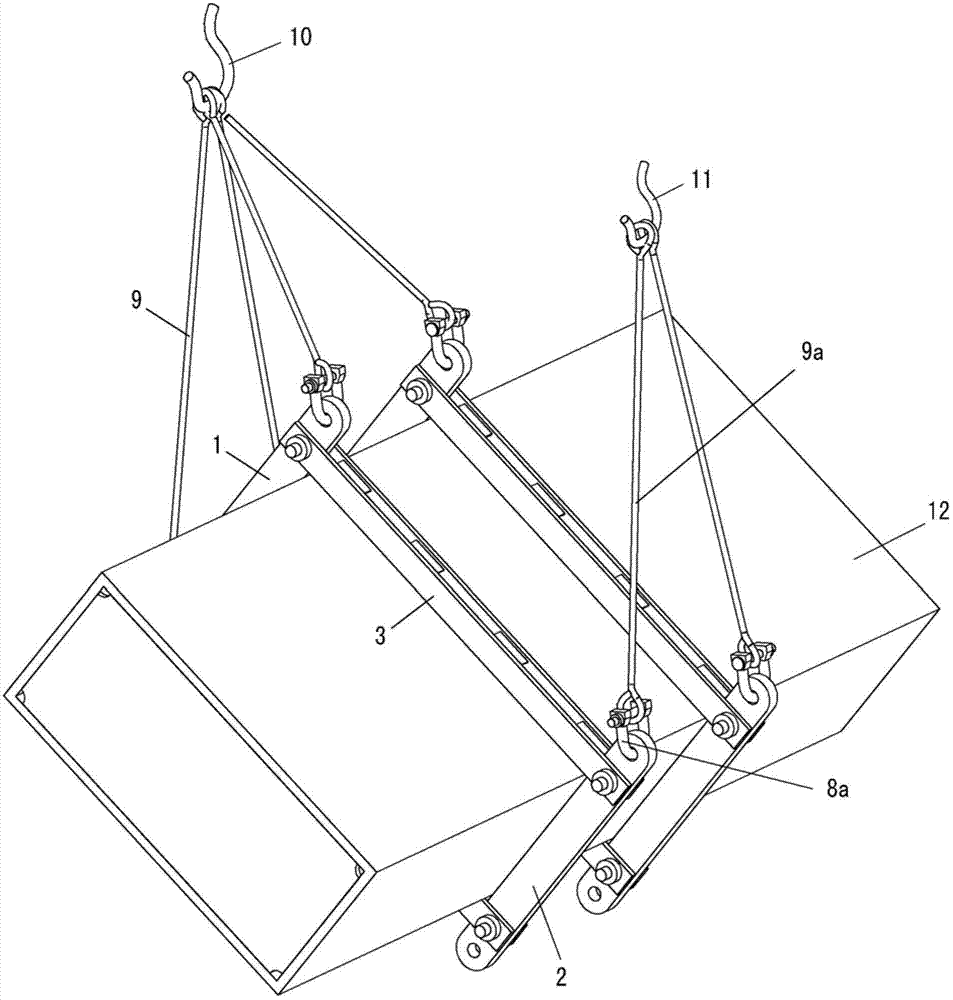

[0024] see figure 1 , the structural form of the oversized cross-section box-shaped member turning over spreader in this embodiment is: a "mouth"-shaped spreader is composed of an upper pole 1, a lower pole 2, and two left and right auxiliary poles 3; wherein, the upper pole 1, the lower pole The shoulder pole 2 is connected with the left and right auxiliary poles 3 through the pin shaft 6 and the pin shaft cap 7; the two ends of the upper pole 1 are respectively provided with the upper pole lifting holes 1a, and the two ends of the lower pole 2 are respectively provided with the lower pole Lifting hole 2a.

[0025] In specific implementation, the auxiliary shoulder pole 3 is composed of two splints 4 and a reinforcement 5 arranged between the two splints 4, and the splint 4 and the reinforcement 5 are welded as a whole; The shoulder pole 2 is clamped, and the structure of this splint makes the production of the auxiliary pole 3 more convenient. If a whole piece of steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com