Method and device for controlling voltage of LCD (liquid crystal display) based on ladder resistance network

A ladder resistor and control method technology, applied in the field of electricity, can solve problems such as large fluctuations in power supply voltage, LCD display ghosts, drops, etc., to achieve the effect of ensuring the display effect and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

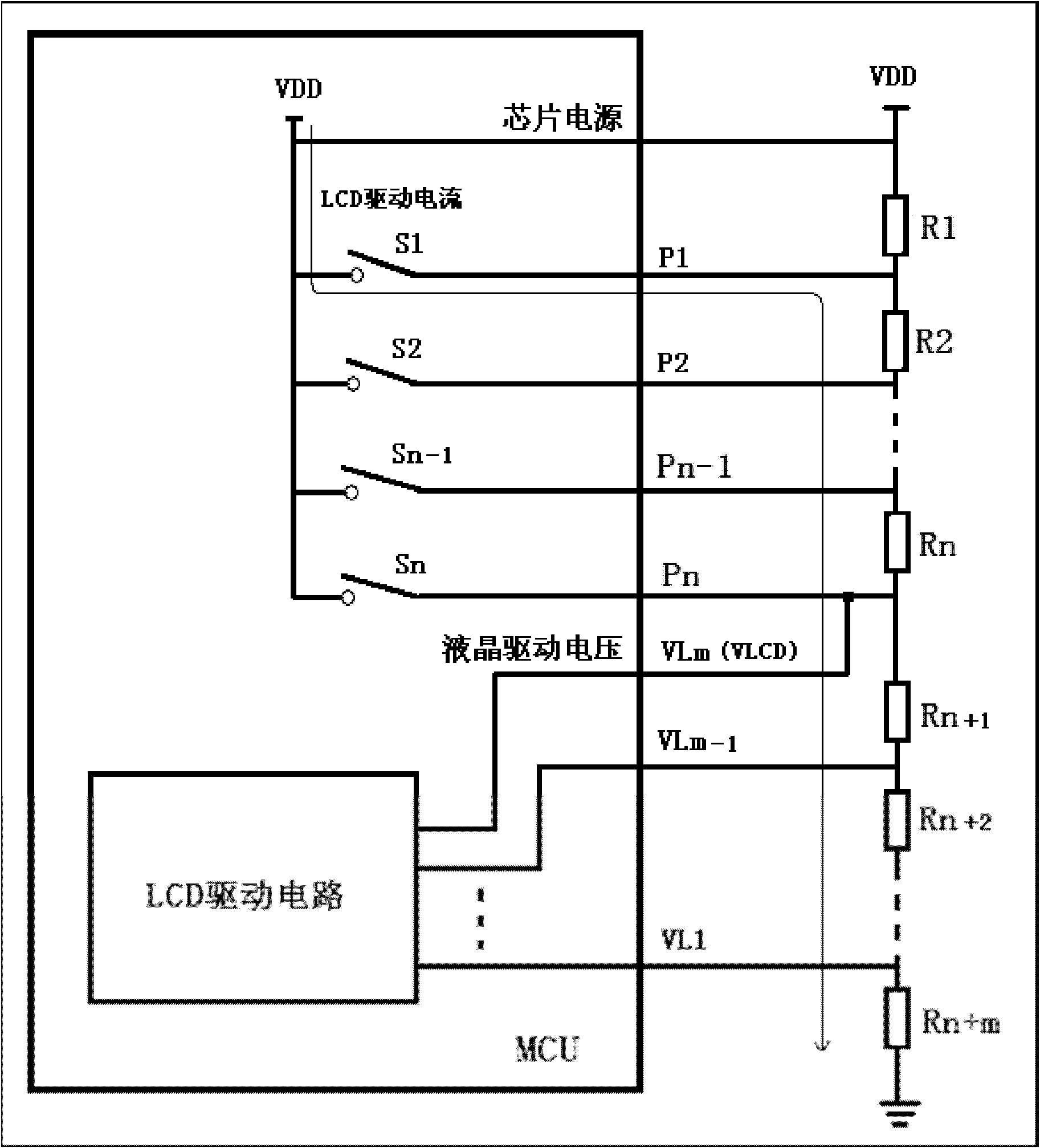

[0015] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

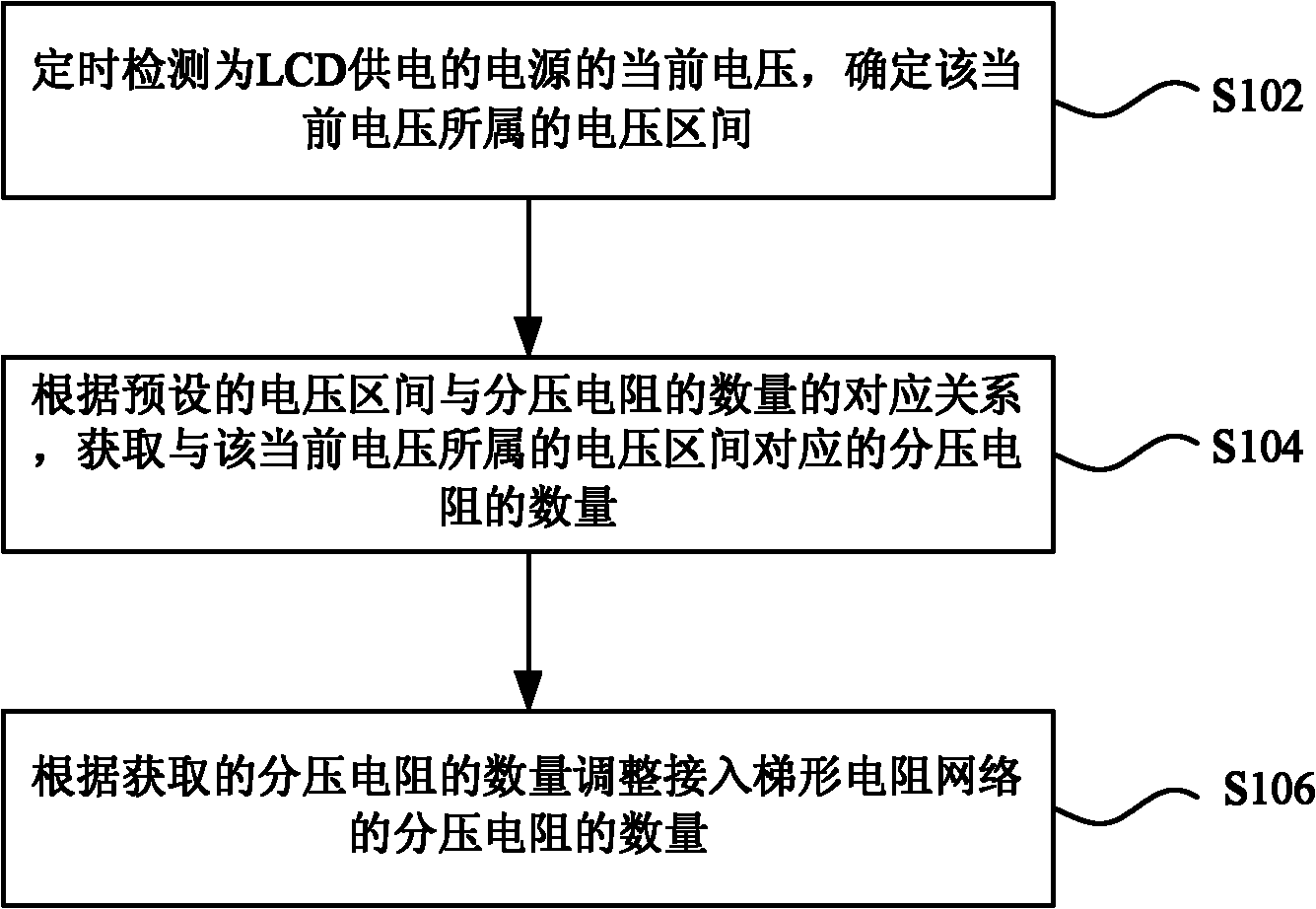

[0016] figure 1 It is a flowchart of a method for controlling LCD voltage based on a ladder resistor network according to an embodiment of the present invention, such as figure 1 As shown, the method mainly includes the following steps (step S102-step S106):

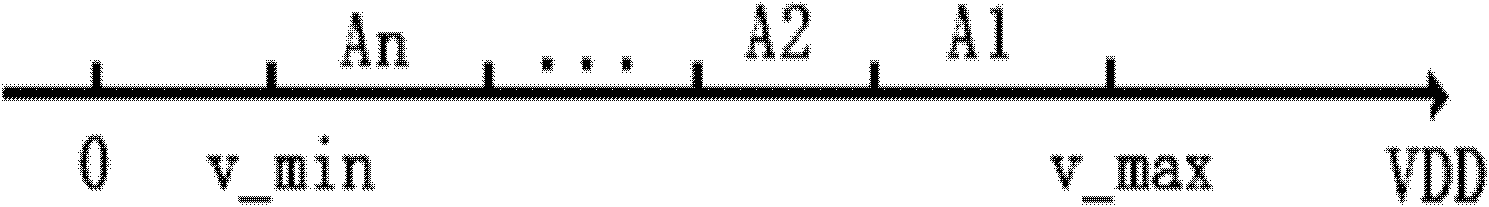

[0017] Step S102, regularly detect the current voltage of the power supply for the liquid crystal display (LCD), and determine the voltage interval to which the current voltage belongs;

[0018] In the embodiment of the present invention, before regularly detecting the current voltage of the power supply for the LCD, the VOP value of the LCD is adjusted through the process, wherein the VOP value after adjustment is smaller than the VOP value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com