Roll stand

A technology of steel rolling frame and arch frame, which is applied in the field of rolling stainless steel, and can solve problems such as unguaranteed, interference, and unreliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

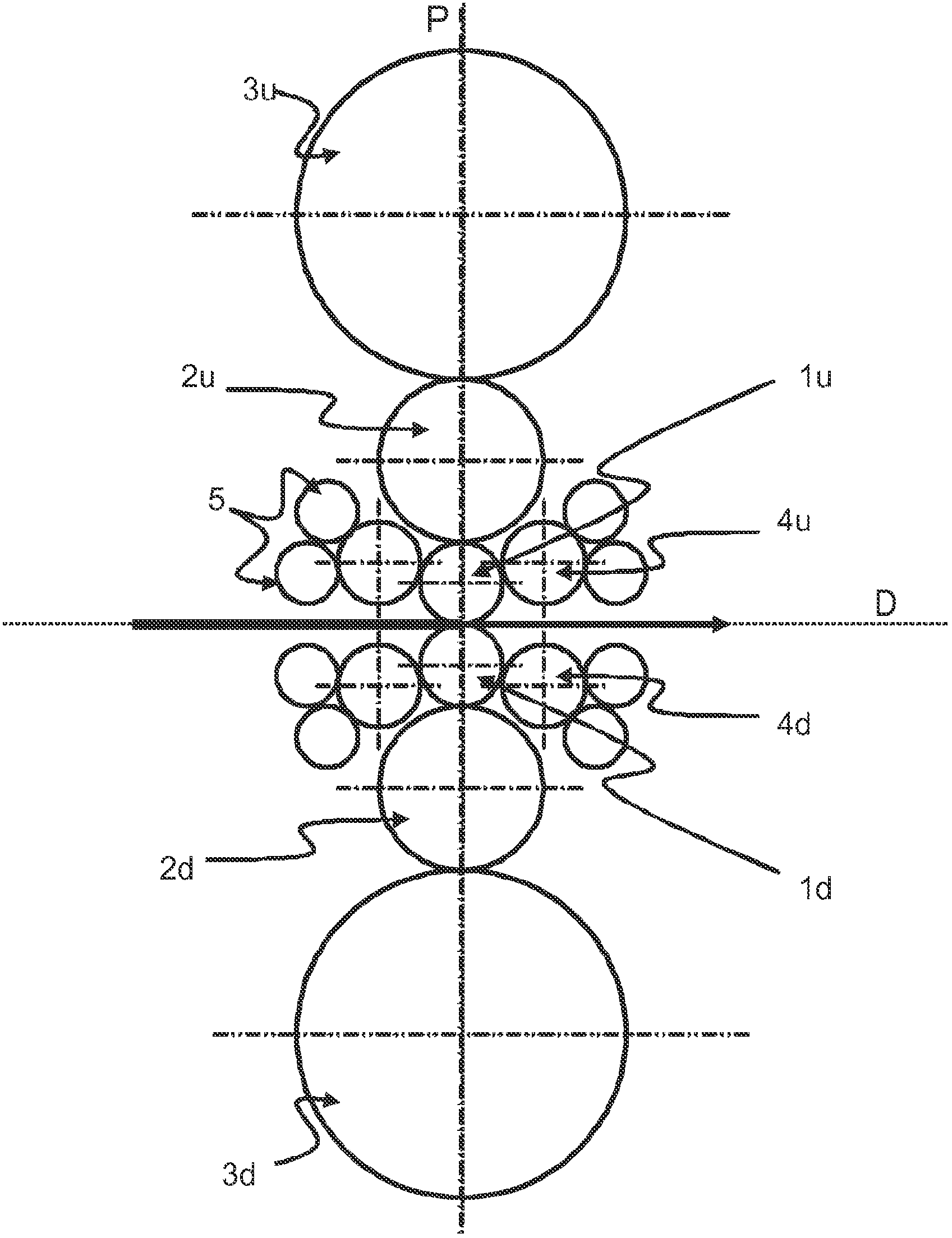

[0055] figure 1 An implementation example of a laterally supported six-roll type rolling stand according to the prior art is shown. Generally, a six-high rolling stand includes two working rolls 1u and 1d with smaller diameters, which are the upper working roll 1u located above the running plane D of the strip to be rolled, and the upper work roll 1u located above the strip to be rolled. The lower work roll 1d below the traveling plane D is moved. The strip to be rolled travels between two work rolls lu, ld supported vertically by a pair of intermediate rolls 2u, 2d, driven in particular by friction, which are themselves pressed against A pair of backup rolls 3u, 3d resting on the pair of intermediate rolls 2u, 2d is vertically supported. The work rolls 1u, 1d have a longitudinal axis of rotation in a plane substantially perpendicular to the plane of travel of the strip, commonly referred to as the clamping plane P. In the case of lateral support, each work roll is not only...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap