Novel debugging clamp plate mechanism

A pressure plate, a new type of technology, applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of inconvenient adjustment and use of the pressure plate, long auxiliary time for adjustment, passive and other problems, achieve good integration effect, improve passive problems, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

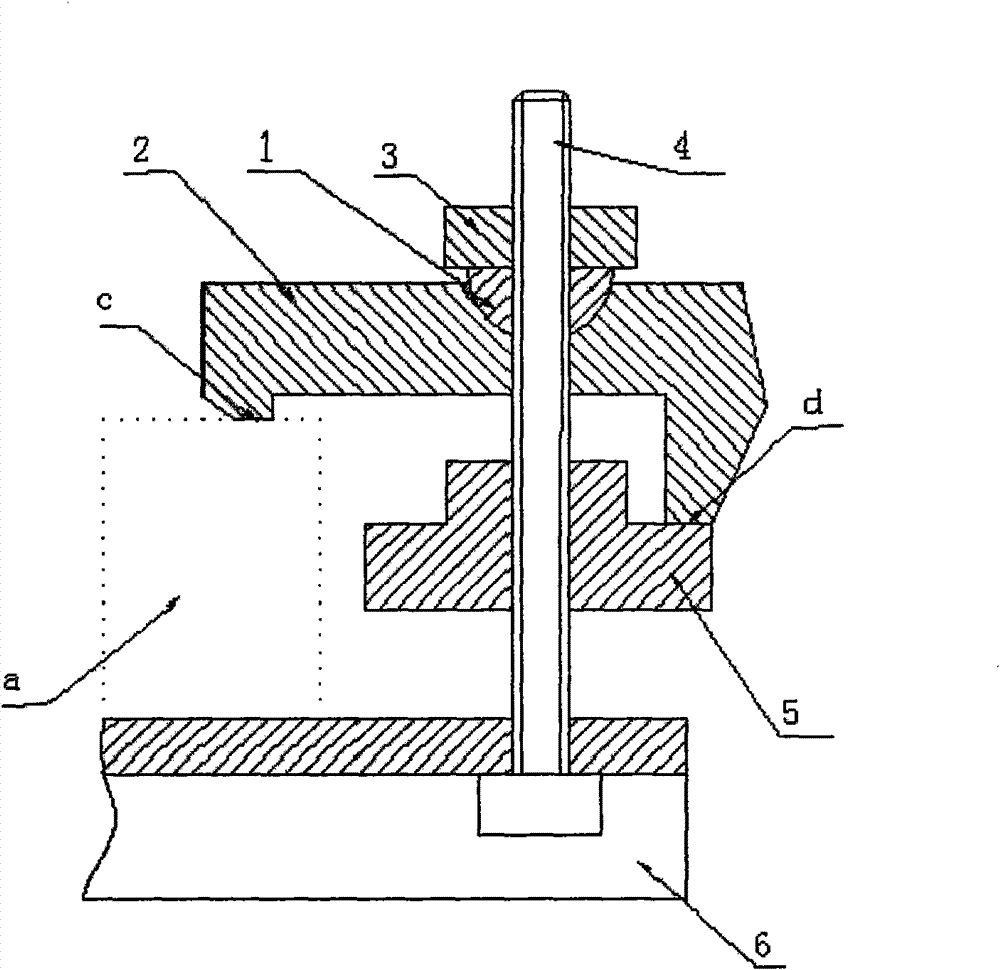

[0009] It consists of a spherical washer 1, an L-shaped pressure plate 2, a positioning nut 3, a T-shaped bolt 4, a stepped nut 5 and a worktable 6; it inserts the T-shaped head of the T-shaped bolt 4 into the T-shaped slot of the machine table 6 , according to the height of the workpiece a, adjust the stepped nut 5 against the end d of the L-shaped pressure plate 2, tighten the positioning nut 3 and clamp the workpiece a on the workbench 6 through the spherical washer 1 and the end c of the L-shaped pressure plate 2 Top: Tighten or loosen the adjustment positioning nut 3 and the step nut 5 to adjust the height of the L-shaped pressure plate clamping and fixing the workpiece a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com