Method for manufacturing oil casing with k55 steel grade steel plate hfw

A technology for oil casing and steel plates, applied in the field of steel pipe manufacturing, can solve the problems of work hardening effect, easy cracking of welding seams, and difficult welding, and achieve the effects of preventing deformation and cracking, improving welding performance and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

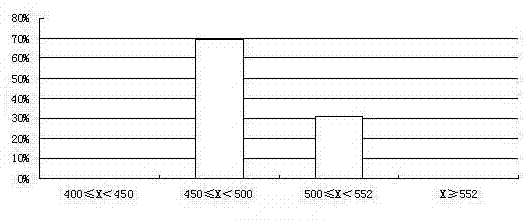

[0024] In order to make the steel pipe longitudinal tensile test results meet API 5CT standard requirements, which is conducive to the forming and welding of coils, the chemical composition and mechanical properties of coils are very strict when purchasing coils. The chemical composition of coils used in the present invention The weight content of the steel is: C 0.22~0.30%, Si 0.10~0.40%, Mn≤1.5%, P≤0.020%, S≤0.010%, K55 carbon equivalent ≤0.60%, and the balance is iron. can meet the above requirements.

[0025] The specific production process of steel pipe is as follows:

[0026] 1. The coil is uncoiled and leveled.

[0027] 2. Shear butt welding: first preheat the edge of the plate, anneal the weld seam after welding, remove the residual stress of the weld seam after welding, prevent deformation and cracking, and ensure that the welding butt joint will not be affected by force after entering the precision forming unit fracture.

[0028] 3. Base metal flaw detection: Ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com