Fault mode visual method based on three-dimensional model of product

A failure mode and three-dimensional model technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to intuitively understand the distribution of failure modes, low acquisition efficiency, and difficulty in understanding the specific location of product failure modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

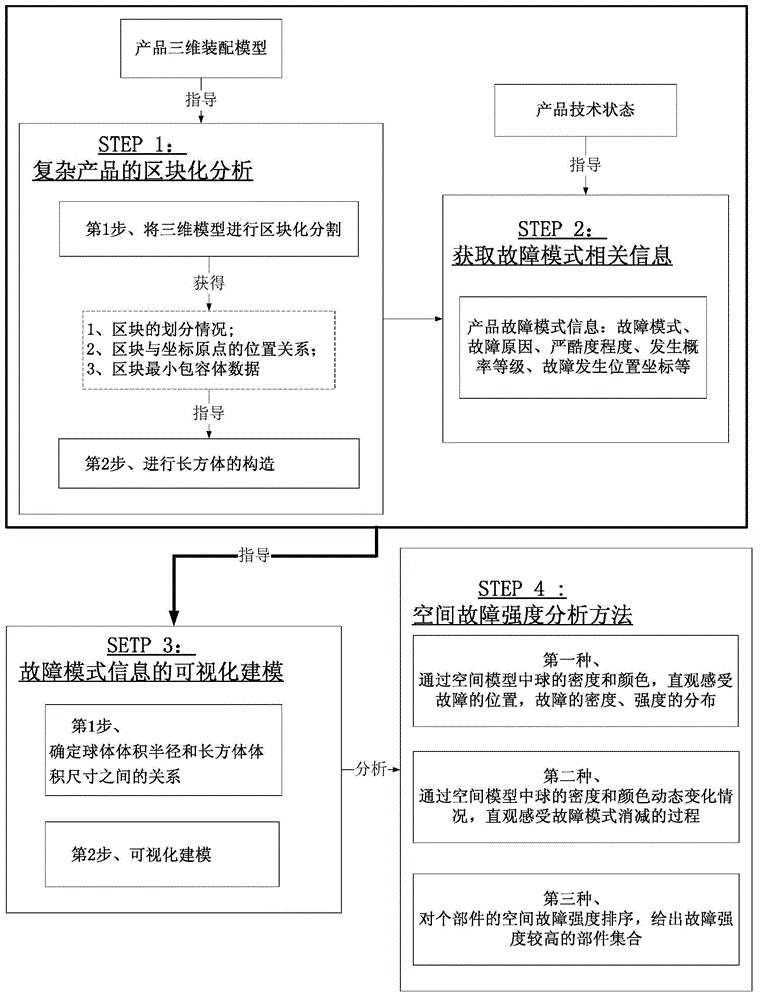

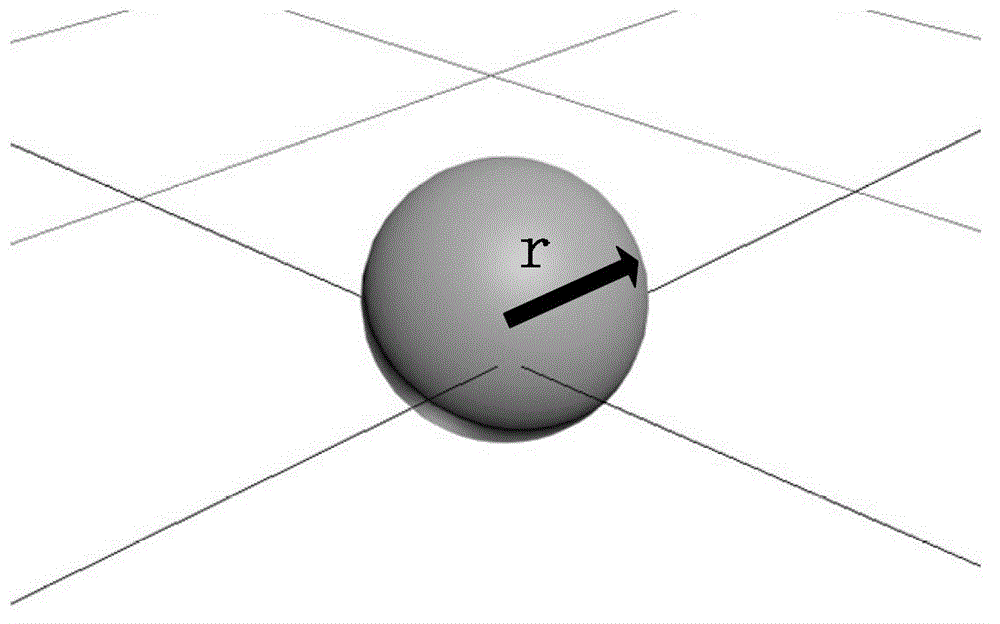

[0113] See Figure 8 , a failure mode visualization method based on a product three-dimensional model of the present invention, it is carried out according to the following four steps:

[0114] Step 1: Block analysis of complex products

[0115] Firstly, on the basis of the 3D assembly model of the product, the lowest agreed level of failure mode analysis is determined, and the 3D model is divided into blocks according to the lowest agreed level product, which are named block 1, block 2, and block 3 respectively. ...and so on. According to the actual situation of the product in space, the position coordinates of the center of each block relative to the coordinate origin (0,0,0) of the 3D model can be obtained respectively, that is, the coordinates of block 1 are (X 1 , Y 1 ,Z 1 ), the coordinates of block 2 are (X 2 , Y 2 ,Z 2 ), ... and so on.

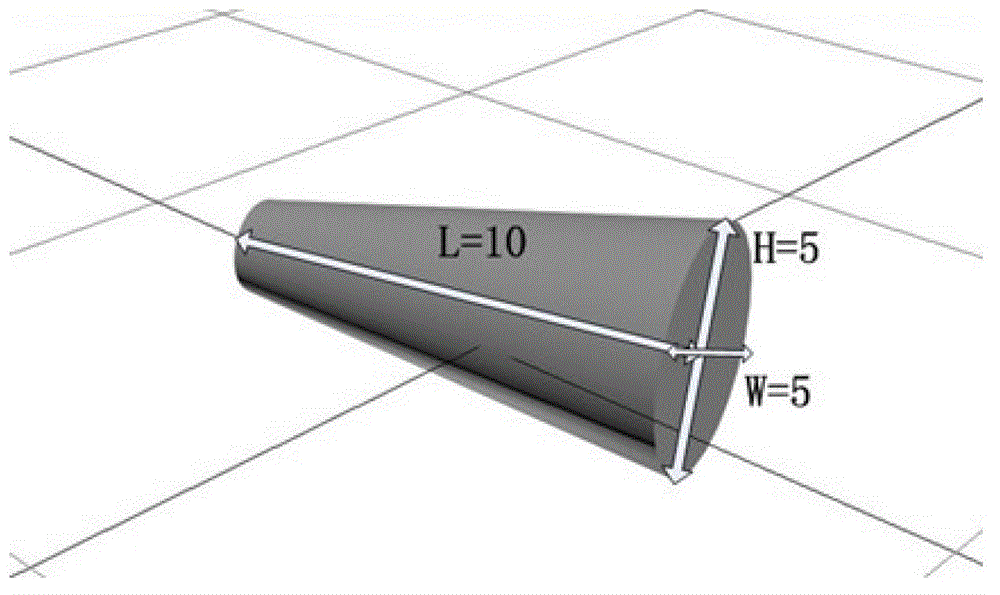

[0116] Then, carry out the construction of cuboid. First, a large cuboid needs to be established to represent the entire sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com