Drilling system and method of operating a drilling system

A technology of drill string and drill floor, which is applied in the field of drilling system with standpipe, and can solve problems such as the inoperability of the steering gear and the maintenance of fluid pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

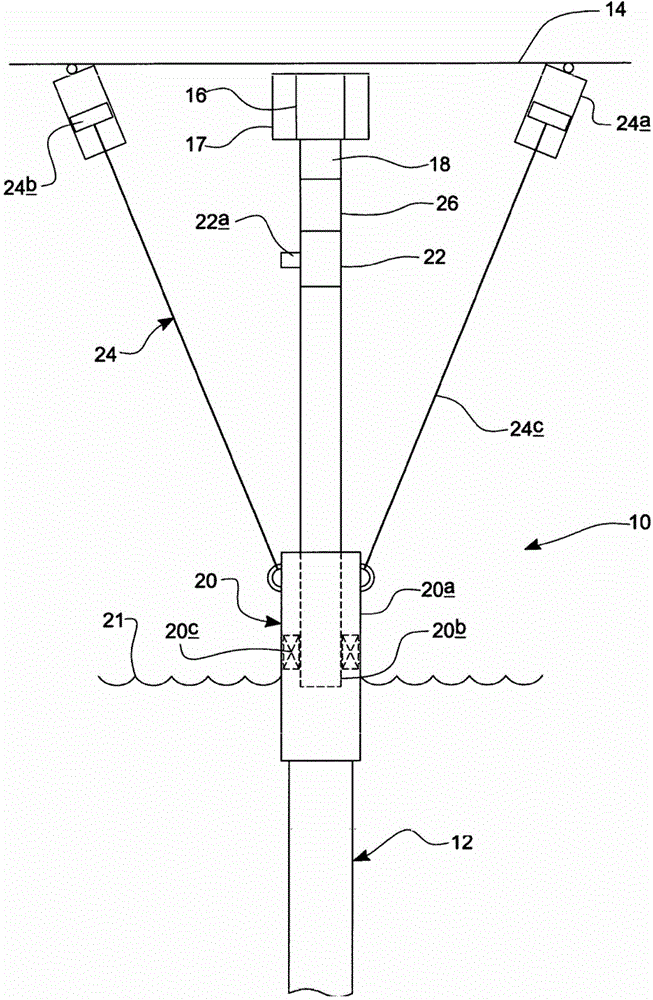

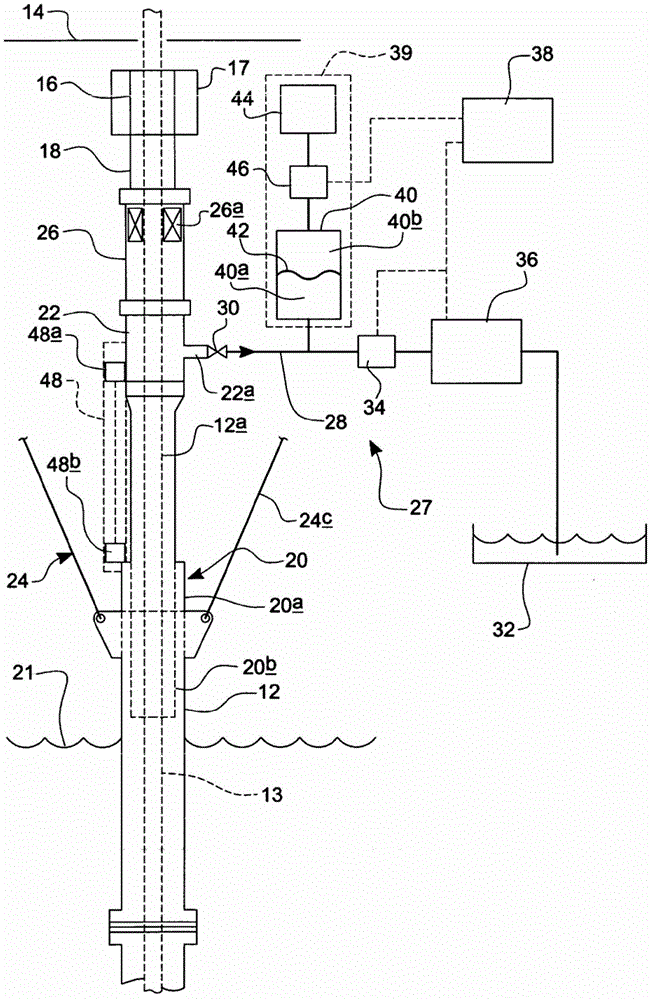

[0030] now refer to figure 1 , shows a riser system 10 comprising a riser 12, the lower end of which connects to a wellhead (not shown), in this example installed at the subsea surface at the wellhead by a blowout preventer (BOP) stack (not shown) or mud pipe. Such as figure 2 As shown, a drill string 13 extends from the wellbore, through the wellhead, the BOP stack, and down to the center of the riser 12 . The upper end of the riser 12 is connected to a drill floor 14 of the floating drilling rig, which is provided with equipment for driving the drill string, usually a rotary table or top drive (not shown). The riser assembly 10 is provided with a diverter 16 which provides an outlet for fluid from the riser 12 and is connected to the upper end of the riser 12 by a conventional ball or flexible joint 18. A ball or flexible joint 18 allows some angular movement of the riser 12 relative to vertical while still maintaining a substantially fluid seal between the riser 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com