Temperature-changing double-layer glass cup

A glass and double-layer technology, which is applied in the direction of drinking water vessels, etc., can solve the problems of no double-layer glass inner and outer walls showing the temperature change effect, destroying the chemical composition of the temperature-changing coating, and wearing off the temperature-changing coating, etc., to achieve structural Simple, low manufacturing cost, safe and hygienic to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

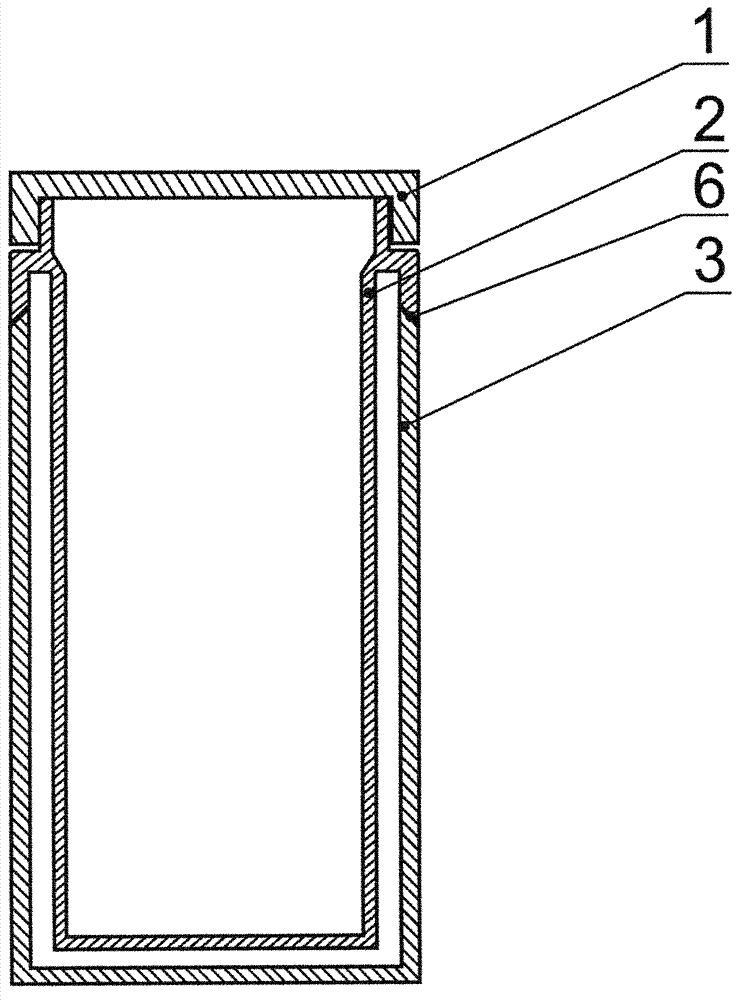

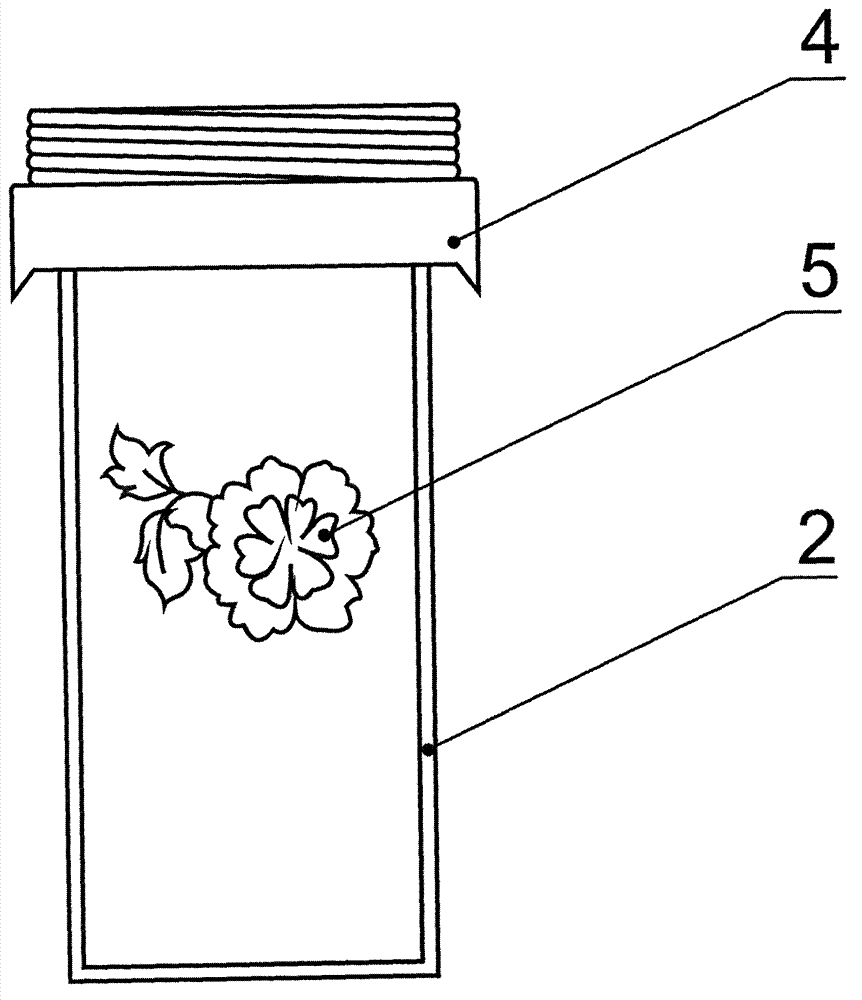

[0017] like figure 1 , figure 2 As shown, the present invention includes an outer cup (3), an inner cup (2) and a lid (1), the outer cup (3) and the inner cup (2) are both made of glass, and the outer wall of the inner cup (2) has a bottom temperature change coating, the induction temperature is 20℃; the bottom layer of temperature change paint has a second layer of temperature change paint, and the second layer has a temperature of 40℃; the second layer of temperature change paint has a third layer of temperature change paint, and the third layer of temperature change paint The temperature is 60°C; the third layer of temperature-change paint has a surface layer of temperature-change paint, and the surface induction temperature is 80°C; the bottom layer of temperature-change paint, the second layer of temperature-change paint, the third layer of tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com